PARTIAL

advertisement

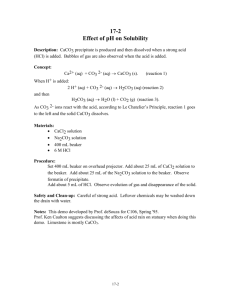

G. Lopes, A. Ferreira, A. P. Gonçalves and J. B. Branco Instituto Tecnológico e Nuclear, Estrada Nacional 10, 2686-953 Sacavém, Portugal Unidade de Ciências Químicas e Radiofarmacêuticas The applications of molten salts have been well recognized for more than a century. In spite of the use of high temperature corrosive liquids, molten salts offer unique opportunities. Low temperature multi component molten salts, as well as room temperature ionic liquids have been developed for materials processing. Currently, molten salts are finding applications in fuel cell technology, in the field of separation processes of minor actinides from the rest of the fission products that are contained in the irradiated nuclear fuel, for the direct catalytic conversion of methane under mild conditions and the partial oxidation of methane to synthesis gas [1]. Here, we report the synthesis, characterization and behaviour for the partial oxidation of methane of potassium-cerium (K-Ce) molten carbonates. All experiments were carried out using an K2CO3-Li2CO3 (50:50 wt.%) eutectic mixture (T=600 ºC) as solvent and the cerium molten carbonates prepared by the addition to this mixture of an appropriate amounts of Ce2(CO3)3 (5 and 15 wt.%). The molten salts were characterized by Differential Scanning Calorimetry (PAC-ATD ADI prototype, DSC recorded under argon-50 mL/min, 20 oC (hold 15 min) until 1000 oC at a 10 oC/ min heating rate), X-Ray Powder Diffraction (XRD, reflection geometry with a PANalitycal X’Pert Pro diffractometer using Cu, ka monochromatic radiation l=1.5406 Å), Infrared Spectroscopy (IR, recorded on a Bruker spectrometer with samples mounted as Nujol mulls) as well as Elemental Analysis (C,H,N, S and O, performed on a CE instrument EA1110 automatic analyzer). DSC tests before catalytic test XRD patterns for the molten salts ΔT (ºC) Intensity (a. u.) 0 300 350 400 450 500 550 600 650 Li2CO3-K2CO3-Ce2(CO3)3 (5%) Li2CO3-K2CO3-Ce2(CO3)3 (15%) 600 700 T (ºC) -0.5 XRD tests were performed before and after the catalytic tests. The melting of the salts leads to the CeO2 formation. -1 -1.5 -2 -2.5 500 400 300 T = 485 ºC -3 200 -3.5 -4 Phase diagram for the eutectic mixture T = 504 ºC 100 Li2CO3 K2CO3 T = 506 ºC -4.5 Li2CO3-K2CO3 -5 Li2CO3-K2CO3-Ce2(CO3)3 (5%) CeO2 0 Li2CO3-K2CO3-Ce2(CO3)3 (15%) 20 30 40 50 60 70 80 2 Theta (degree) Melting temperatures between 484 ºC and 506 ºC; The addition and increase of cerium % decreases the transition temperature IR results for the molten salts DSC tests after catalytic test Transmittance (%) ΔT (ºC) 0 100 300 350 400 450 500 550 600 650 700 90 T (ºC) -0.5 80 -1 70 60 T = 496 ºC -1.5 50 New features are not seen before and after the catalytic reaction. Slight contraction of the CeO2 lattice is observed. -2 -2.5 -3 40 30 20 10 T = 502 ºC -3.5 ν(C=O) 878 cm-1 0 T = 506 ºC -4 ν(C-O) 1056 cm-1 Li2CO3-K2CO3 Li2CO3-K2CO3-Ce2(CO3)3 (5%) 3700 3200 2700 2200 1700 1200 700 Wavenumber (cm-1) Li2CO3-K2CO3-Ce2(CO3)3 (15%) Li2CO3-K2CO3-Ce2(CO3)3 (5%) Li2CO3-K2CO3-Ce2(CO3)3 (15%) Characteristic bands of CO3. The study of the Gas Hourly Space Velocity (GHSV, mL of CH4 / g of catalyst. h) and CH4 /are O2 molar ratiobefore was undertaken. New features not seen and after The outlet gas composition was analyzed on-line by gas chromatography (GC) with a thermal conductivity detector (TCD). Catalyst activity was defined as the number of mL of methane converted per g of catalyst and per hour (mLCH4/g.h), m≈25 g. the catalytic reaction. Conv. CH4 (%) Conv. CH4 (%) 14 Slight contraction of the CeO2 lattice is observed. 9 8 12 Selectivity (%) 46.7 50 45 7 10 42.6 40 6 Li2CO3-K2CO3-Ce2(CO3)3 (15%) 35 8 5 30 4 6 25 3 20 4 2 2 0 2500 1 10 0 3500 4500 5500 6500 7500 8500 0 1 2 GHSV (mL/g.h) Li2CO3-K2CO3 Li2CO3-K2CO3-Ce2(CO3)3 (5%) 3 4 5 6 7 8 9 CH4/O2 molar ratio Li2CO3-K2CO3-Ce2(CO3)3 (15%) Effect of GHSV at CH4/O2 molar ratio = 2 Lower GHSV and CH4/O2 molar ratio influences the catalyst activity. CO2 is the only product of the reaction. 10.2 15 Li2CO3-K2CO3 Li2CO3-K2CO3-Ce2(CO3)3 (5%) 0 Sel. CO Li2CO3-K2CO3-Ce2(CO3)3 (15%) Effect of CH4/O2 molar ratio at GHSV= 8520 Sel. CO2 Sel. C2 Sel. C3 Selectivity results for GHSV = 2863 and CH4/O2 molar ratio = 2 Conversion of methane increases with the increase of the cerium amount. [1] a) B. Mishra et al., Journal of Physics and Chemistry of Solids, 2005, 66, 396; b) T.R. Griffiths et al., Journal of Alloys and Compounds, 2006, 418, 116; c) J.J. Peng, et al., Applied Catalysis A: General, 2000, 201, L55; d) Y.G. Wei, et al., Journal of Natural Gas Chemistry, 2007, 16, 6. 0.4 5 Molten carbonate with 15% Ce is the only that shows selectivities to hydrocarbons This work was supported by FCT, under contract number PTDC/QUI/72290/2006