bte 1013 test 2 revision dec2011

advertisement

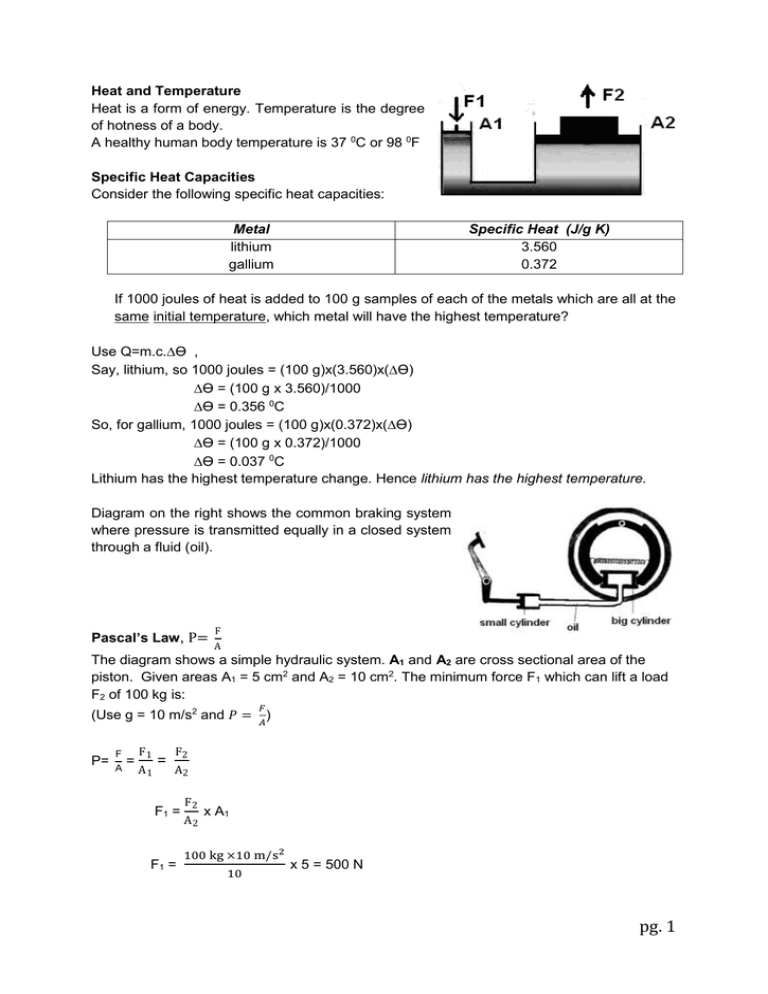

Heat and Temperature Heat is a form of energy. Temperature is the degree of hotness of a body. A healthy human body temperature is 37 0C or 98 0F Specific Heat Capacities Consider the following specific heat capacities: Metal lithium gallium Specific Heat (J/g K) 3.560 0.372 If 1000 joules of heat is added to 100 g samples of each of the metals which are all at the same initial temperature, which metal will have the highest temperature? Use Q=m.c.Ө , Say, lithium, so 1000 joules = (100 g)x(3.560)x(Ө) Ө = (100 g x 3.560)/1000 Ө = 0.356 0C So, for gallium, 1000 joules = (100 g)x(0.372)x(Ө) Ө = (100 g x 0.372)/1000 Ө = 0.037 0C Lithium has the highest temperature change. Hence lithium has the highest temperature. Diagram on the right shows the common braking system where pressure is transmitted equally in a closed system through a fluid (oil). Pascal’s Law, P= F A The diagram shows a simple hydraulic system. A1 and A2 are cross sectional area of the piston. Given areas A1 = 5 cm2 and A2 = 10 cm2. The minimum force F1 which can lift a load F2 of 100 kg is: 𝐹 𝐴 (Use g = 10 m/s2 and 𝑃 = ) P= F A = F1 A1 = F2 A2 F1 = F1 = F2 A2 x A1 100 kg ×10 m/s2 10 x 5 = 500 N pg. 1 Machine and Engine Power A machine is is a device that can change magnitude or line of action, or both magnitude and line of action of a force ie. reduces human effort. Engine power can be measured with a dynamometer/ dyno. The actual engine power that actually reaches the output shaft or flywheel of an engine is also known as brake power. Formula for engine power: Indicated mean effective pressure, imep= (effective area of indicator diagram/base length of the diagram)×constant *constant is given in test/exam. Indicated power (ip) is the power that is developed inside the engine cylinders Example calculation: In a test, a single-cylinder 4-stroke engine develops a mean effective pressure of 5 bar at a speed of 3000 rev/min. The length of the engine stroke is 0.12 m and the cross-sectional area of the cylinder bore is 0.008 m2. Calculate the indicated power of the engine in kW. The engine is single-cylinder 4-stroke, so there is one working stroke for every two revolutions. N, the number of working strokes per second N = 3000÷60/2 = 25; P = 5 bar = 500 000 N/m2, l = 0.12 m; a = 0.008 m2. Substituting these values in the formula gives indicated power, ip = 500 000 × 0.12 × 0.008× 25/1000 kW = 12 kW Heat, Specific Heat Capacity and Latent Heat You may use Q=m.c. Ө and Q=m.Lf 1. Calculate the temperature change, ɵ, of 3 kg of aluminium when supplied with 5000 J of heat? Given the specific heat capacity of aluminium is 950 J kg-1 0C -1. Solution: Use Q=m.c.Ө. So 5000 = 3 x 950 x Ө Ө = 5000/(3x950) Ө = 1.75 0C 2. Calculate the amount of heat, Q required to change 10 kg of ice into liquid water at 0°C, given the specific latent heat of fusion is 335,000 J/kg. Solution: Q=m.Lf Q = 10 x 335000 Q = 335,000 J Q = 3.35 x 105 J pg. 2 3. Calculate the amount of heat required to convert 5.0 kg of water at 20°C to steam at 100°C. The specific heat capacity of water in this temperature range is 4200 J kg-1 0C-1 and the specific latent heat at 100°C for liquid to vapour is 2,257,000 J/kg. Solution: Total heat, Qtotal = m.c.Ө + m.Lf Qtotal = [5x4200x(100 – 20)] + [ 5 x 2,257,000] Qtotal = 1,680,000 J + 11,285,000 J Qtotal = 12,965,000 J = 12,965 kJ = 1.2 x 107 J Machine Terms: Mechanical advantage; Velocity ratio/ movement ratio; Machine efficiency A simple machine raises a load of 160 kg through a distance of 1.6 m. The effort applied to the machine is 200N and moves through a distance of 16 m. Taking g as 9.8 m/s2, determine: a) the force ratio, b) movement ratio/ velocity ratio, and c) machine efficiency (in percentage) Solutions: a) Force ratio = Load/effort = 160kg/200 N = (160 x 9.8) N/200 N = 7.84 b) Velocity ratio (movement ratio) = distance moved by effort/distance moved by the load = 16 m/1.6 m = 10 c) Efficiency = (force ratio/ velocity ratio) x 100% = (7.84/10) x 100 = 78.4% Gears in engine Use this ratio: 𝑆𝑝𝑒𝑒𝑑 𝑜𝑓 𝑑𝑟𝑖𝑣𝑒𝑟 𝑆𝑝𝑒𝑒𝑑 𝑜𝑓 𝑓𝑜𝑙𝑙𝑜𝑤𝑒𝑟 = 𝑡𝑒𝑒𝑡ℎ 𝑜𝑛 𝑓𝑜𝑙𝑙𝑜𝑤𝑒𝑟 𝑡𝑒𝑒𝑡ℎ 𝑜𝑛 𝑑𝑟𝑖𝑣𝑒𝑟 A driver gear on a shaft of a motor has 35 teeth and meshes with a follower having 98 teeth. If the speed of the motor is 1400 revolutions per minute, find the speed of rotation of the follower. Solution: Speed of driver = speed of follower teeth on follower teeth on driver 1400 / speed of follower = 98/35 Speed of follower = (1400 x 35)/98 = 500 rev/min pg. 3 A compound gear train similar to that shown in last figure consists of a driver gear A, having 40 teeth, engaging with gear B, having 160 teeth. Attached to the same shaft as B, gear C has 48 teeth and meshes with gear D on the output shaft, having 96 teeth. Determine; (a) the movement ratio of this gear system (b) the efficiency ratio when give, the force ratio is 6 (a) The speed of D = speed of A x TA/TB x TC/TD movement ratio = NA/ND = TB/TA x TD/TC = 160/40 x 96/48 =8 (b) The efficiency = (force ratio/movement ratio) x 100% = 6/8 x 100 = 75% ENGINE POWER Use these equations: 1. Indicated Mean Effective Pressure, IMEP = effective area of indicator diagram base length of the diagram × 𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡 2. Indicated power (IP) = (P ×l×a×N)/1000 (in kW) where P = mean effective pressure in N/m2, l = length of engine stroke in m, a = cross sectional area of cylinder bore in m2, N = number of working strokes per second. An indicator diagram taken from a single-cylinder 4-stroke engine has an effective area of 600 mm2. If the base length of the indicator diagram is 60 mm and the constant is 80 kPa/mm, calculate the indicated mean effective pressure. Solution: Indicated mean effective pressure or (imep)= (effective area of indicator diagram/base length of the diagram)×constant imep = (600/60)×80 kPa/mm imep = 800 kPa = 8 bar In a test, a single-cylinder 4-stroke engine develops a mean effective pressure of 5 bar at a speed of 3000 rev/min. The length of the engine stroke is 0.12 m and the cross-sectional area of the cylinder bore is 0.008 m2. Calculate the indicated power of the engine in kW. Solution: The engine is single-cylinder 4-stroke, so there is one working stroke for every two revolutions. N, the number of working strokes per second, N = (no. of cylinders/2)x(no.of revolutions/second)= (4/2)x[(3000 revs/minute)x(1 minute/60 seconds)] = 100; P = 5 bar = 500 000 N/m2, l = 0.12 m; a = 0.008 m2 Substituting these values in the formula gives ip = (500 000) × (0.12) × (0.008) × (100) W = 48000 W = 48 kW pg. 4