Medical Device Engineering

advertisement

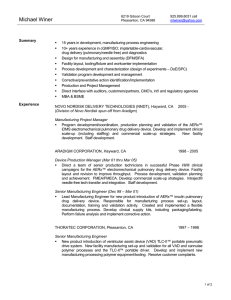

Jim Niederjohn April 2, 2014 Discuss the role that engineers play in the medical device industry Jim’s Background ◦ Education ◦ Career History ◦ Medical Devices & Projects Medical Device Engineering Advice ◦ Engineering Roles & Responsibilities ◦ How to develop and release a medical device to market ◦ Career ◦ College Questions Moved to Newark, CA in 1984 Graduated from Newark Memorial High School in 1990 Graduated from CSU Chico in 1994 ◦ BS Mechanical Engineering Graduated from Santa Clara University in 2000 ◦ MBA A *medical device is "an instrument, apparatus, implement, machine, contrivance, implant, in vitro reagent, or other similar or related article, including a component part, or accessory which is: recognized in the official National Formulary, or the United States Pharmacopoeia, or any supplement to them, intended for use in the diagnosis of disease or other conditions, or in the cure, mitigation, treatment, or prevention of disease, in man or other animals, or intended to affect the structure or any function of the body of man or other animals, and which does not achieve any of its primary intended purposes through chemical action within or on the body of man or other animals and which is not dependent upon being metabolized for the achievement of any of its primary intended purposes." *http://www.fda.gov/aboutfda/transparency/basics/ucm211822.htm ‘00 Startup 95 CRYOVASCULAR SYSTEMS Acquisition Big company ’05 Acquisition ’10 ‘15 Manufacturing Engineer (1994 – 1998) ◦ Support all activities related to building product ◦ Make sure that the production line is meeting throughput and yield goals ◦ Skills developed Product assembly knowledge Problem solving / troubleshooting – root cause analysis Fixture Design Process Development & Optimization Design of Experiments (DOE) Manufacturing Documentation Engineering Change Orders (ECO) Product non-conformities and dispositioning Protocol and report writing R&D Project Engineer (1998 – 2001) ◦ Perform development activities to release products to market ◦ Skills developed Component design Injection molding familiarity Project planning / Schedule development Coordination of activities with other team members Product Qualification familiarity Biocompatibility testing Sterilization Validation Design Verification (DV) testing Accelerated Aging DV testing Design Validation testing Manufacturing Process Validations Packaging Validation Regulatory requirements for gaining approval R&D Manager (2001 –2003) ◦ Project Manager responsible for releasing products to market ◦ Supervise team of R&D engineers & technicians ◦ Lead team of cross functional resources ◦ Skills developed General Project Management Getting “buy in” on decisions Setting expectations when working with others Holding individuals accountable Developing (Coaching & mentoring) team CRYOVASCULAR SYSTEMS Manufacturing / Project Manager (2003 –2007) ◦ Production supervisor responsible for achieving manufacturing goals ◦ Supervise production operators and mfg. engineers ◦ Oversee development of Next Generation Device Process Development Manager (2007 – 2009) ◦ Manage team of process development engineers and technicians Develop manufacturing processes for new products Perform all manufacturing deliverables to qualify device R&D Manager (2009 – present) ◦ Manage team of R&D Engineers and technicians Develop and release new products to market ◦ Employee Career Development ◦ Skills developed Design For Manufacturability Larger scale program management Strategic level planning for product pipeline “Off Pump” Coronary Artery Bypass (OPCAB) Grafting – Minimally Invasive approach Stabilizer Blower / Mister Xpose Coronary Shunt Cryoplasty Catheter ◦ “Cooling therapy” treatment for blocked leg arteries RF Ablation Catheter ◦ Treatment to destroy small areas of heart tissue to prevent abnormal heartbeats UROLIFT System ◦ Deliver implant(s) to relieve prostate obstruction and open the urethra directly by retracting the obstructing prostatic lobes MitraClip – Percutaneous mitral valve repair ◦ Treatment of Mitral Regurgitation (MR) - blood flows backward from the heart’s left ventricle to the right ventricle MitraClip System MitraClip Research & Development Engineer - - Research: Identify a clinical need and evaluate concepts to meet need Development: Develop a concept into a device and release to market - Solid modeling (CAD) to design parts - Build & test prototypes - Interfacing with customers (physicians) - Solving technical issues - Qualification testing of product Sustaining: Run the business design changes to existing products - Corrective and Preventive Action (CAPA) projects - Same as Development (above) - - Manufacturing Engineer Sustaining: Support manufacturing line to achieve throughput and yield goals - Address manufacturing line down issues - Continuous improvement projects to reduce costs (improve cycle time, reduce # of rejects, etc.) & improve reliability New product support: Develop manufacturing processes to support new product development - Fixture & equipment design - Process capability studies / DOE’s - Qualification testing of processes - Developing manufacturing documentation - - Quality Engineer Sustaining: Audit and monitor the quality of product built to ensure that it is meeting the customer’s expectations and all the internal requirements - Address non-conformities with components and assemblies (incoming inspection & production) - Monitor product performance based on complaint analysis - Corrective and Preventive Action (CAPA) projects - Support audits by regulatory bodies Projects / New Products: support development teams who are making design / process changes - Compliance to internal procedures for making changes - Risk Management / Failure Mode Effects Analysis - - Supplier Quality Engineer Sustaining: Audit and monitor supplier performance and ensure that they have capable processes that produce components that meet all the requirements - Address line down issues related to component issues - Perform supplier audits Projects / New Products: Develop and qualify suppliers for design changes / new products - Develop robust and capable inspection methods - Supplier capability assessments - Qualification testing of supplier processes - Project Manager Manage activities to achieve program goals - Develop and execute on project plans to achieve project timeline - Facilitate cross functional team activities - Manage high risk activities related to the project and develop plans to address - Communicate project status to management 5 Design Control Phases ◦ “PASS” gates to move on to the next phase Concept Development • Define clinical need • Identify goals • Identify and evaluate concepts • Recommendation for further development Design Freeze • Finalize specifications • Converge to one concept • Finalize design and show evidence of achieving requirements Design Verification & Validation • Complete functionality testing Manufacturing Readiness • Complete full process validation testing Market Launch • Complete all design control requirements • Gain regulatory approval • Build product for launch Early Years (1st couple of years out of school) Be a sponge – learn as much as you can! Set daily / weekly goals for yourself (i.e. complete task X by Friday) & prioritize based on importance Put your personal life “on hold” when you are working Be clear on your manager’s expectations and understand what is important to him/her Be pro-active and do more than what is expected Develop good working relations with the team you are working with Find a mentor (engineer) and meet semi-regularly to get input and feedback Don’t be afraid to make a mistake… you’ll learn from it Force yourself to do the things that are hard for you Find out what you really like to do College College Early Years (1st couple of years out of school) Be a sponge – learn as much as you can! Set daily / weekly goals for yourself (i.e. complete task X by Friday) & prioritize based on importance – attend classes, complete assignments on time Put your personal life “on hold” when you are working on school projects Be clear on your manager’s expectations and understand what is important to him/her you Be pro-active and do more than what is expected Develop good working relations with the team you are working your classmates with professor Find a mentor (engineer) and meet semi-regularly to get input and feedback Don’t be afraid to make a mistake… you’ll learn from it Force yourself to do the things that are hard for you Find out what you really like to do Do homework and assignments with a team of 3 to 4 people Go to your professor’s office hours Enjoy the college experience!