Chapter 8

advertisement

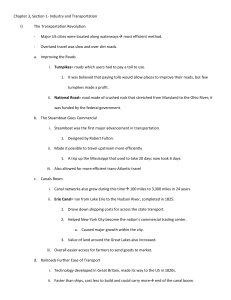

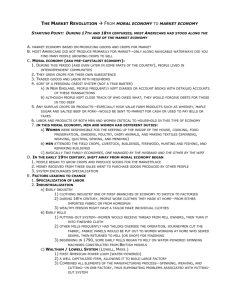

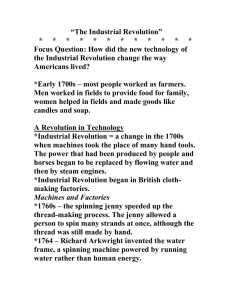

Chapter 13 Industrial Growth in the North (1790 - 1860) Chapter 13 Industrial Growth in the North (1790 - 1860) Section 1 The Industrial Revolution and America The Industrial Revolution Period of rapid growth in the use of machines in manufacturing and production In the early 1700s, most people in Europe and the United States were farmers First industry to fully mechanize – textiles Richard Arkwright patented the water frame (ran on water power) The speed of cloth making increased when workers could produce dozens of threads at the same time, using the water frame Samuel Slater Before he came to America, he was a skilled mechanic in Britain Immigrated to U.S. from Britain bringing with him knowledge of how to build machines even though Parliament had passed a law making it illegal to leave the country with mill machines or plans The first successful textile mill in the United States was established in 1790 at Pawtucket, Rhode Island Built by Slater, Smith Brown, and William Almy Samuel Slater (continued) American businesspeople began building more textile mills after observing the successful partnership between Slater, Brown, and Almy Eli Whitney’s Manufacturing Breakthrough Contributed concepts of mass production and interchangeable parts to American industry Workers could more easily assemble products and replace defective parts if the products had interchangeable parts War of 1812 and Manufacturing Before the War of 1812, Americans were reluctant to build new factories and machinery because British manufacturers could produce large amounts of goods and charge lower prices During the war, many began to realize they relied too much on foreign goods Chapter 13 Industrial Growth in the North (1790 - 1860) Section 2 Changes in Working Life Rhode Island System Used in the Pawtucket mill by Samuel Slater Entire families provided labor and were hired to move to the mill towns and work in the mills The Lowell System Hired young unmarried women from local farms instead of families (Lowell girls) The first textile mill using the Lowell system was built in Waltham, Massachusetts in 1814 Success led to bigger mill in town later named Lowell Young women for across New England went to work in the Lowell mills The typical female employee in the Lowell mills stayed for about 4 years The Lowell Offering wrote about the lives of mill workers Workers Organize Craftspeople (made goods by hand) felt threatened by the spread of factories The spread of factories resulted in lower salaries for workers hired by shop owners Increased competition for factory jobs in the 1840s was the result of the Panic of 1837 and a wave of immigration Factory workers formed unions Most employers against – would not hire union member Workers Organize (continued) To convince business owners to listen to them, workers sometimes staged strikes, refusing to work until employers met union demands Early strikes by union members were not very successful because judges and police usually supported companies against striking union members Labor Reform Efforts Van Buren (1840) granted 10 hour work day to many federal employees At the same time that government employees worked 10-hour days, most private employees put in 12-14 hours, six days a week Connecticut, Maine, New Hampshire, Ohio, Pennsylvania and others passed 10 hour work day laws Company officials in the U.S. avoided laws requiring a 10 hour workday by requiring workers to sign special contracts with longer hours The first successful textile mill in the United States was established in a. the early 1790s at Pawtucket, Rhode Island. b. 1769 by Richard Arkwright. c. Waltham, Massachusetts, by Francis Cabot Lowell. d. Lowell, Massachusetts, by Samuel Slater. Parliament passed laws making it illegal to a. sell cloth to foreign countries. b. run factories using the Rhode Island system. c. use interchangeable parts in gun manufacture. d. leave the country with mill machines or plans. The practice of hiring entire families to work in factories became known as a. the Rhode Island system. b. mass production. c. the Lowell system. d. Fulton’s Folly. To convince business owners to listen to them, workers sometimes staged strikes, a. voting for candidates who agreed with them. b. destroying machines and equipment, thus disabling the factory. c. refusing to work until employers met union demands. d. working for other companies until the original employer raised salaries. Early strikes by union members were not very successful because a. no skilled workers belonged to labor unions until the 1870s. b. most union members were satisfied with working conditions. c. the courts and police usually supported companies against striking union members. d. factory owners usually gave in to demands before a strike could take place. By making workers sign special contracts to work longer hours, company officials in the United States a. produced more textiles than any other nation in the world. b. were able to open more factories that doubled work opportunities for people in New England. c. avoided labor laws regarding the length of the workday. d. were able to pay workers higher salaries while saving on production costs. Workers could more easily assemble products and replace defective parts if the products a. had interchangeable parts. b. were close to cities and transportation centers. c. were protected from industrial espionage. d. were tested before being shipped to major consumers such as the U.S. government. The speed of cloth making increased when workers could produce dozens of threads at the same time, using the a. water frame. b. cotton thread loom. c. sewing machine. d. water wheel. In the early 1700s, most people in Europe and the United States were a. merchants. b. skilled workers. c. carpenters. d. farmers. Before the War of 1812, Americans were reluctant to build new factories and machinery because a. the Gibbons v. Ogden decision discouraged commerce between states. b. New England lacked the fast-flowing rivers needed to power the mills. c. Eli Whitney’s new principle made factories seem obsolete. d. British manufacturers could produce large amounts of goods and charge lower prices. Living History: Living During the Industrial Revolution Chapter 13 Industrial Growth in the North (1790 - 1860) Section 3 The Transportation Revolution New Ways to Travel The Transportation Revolution was a rapid growth in speed and convenience of travel in the U.S. 1800s Growth in communication, trade, and travel during the 1800s was made possible by the invention of the steamboat, the invention of the railroad, and the expansion of roads and canals The Steamboat One of the first breakthroughs of the transportation revolution On August 9, 1807, Americans were awed when the Clermont traveled up the Hudson River with no problems The speed and economy of steamboats caused a boom in trade and encouraged more settlers to move to the Midwest Could carry people and goods across the ocean by the 1850s Gibbons v. Ogden Growth of steamboat shipping industry led to first Supreme Court ruling on interstate commerce Gibbons operated steamboats between New Jersey and Manhattan using federal license (did not have state license to travel in New York waters) New York gave Ogden monopoly on steamboat business Ogden sued Gibbons and won – Gibbons appealed Supreme Court ruled Gibbons had the right to operate in New York – federal law overruled state law – federal license had priority over state license Gibbons v. Ogden (continued) Ruling reinforced federal government authority over states Ruling expanded definition of commerce to include transportation of people One of Marshall’s most important decisions – tore down a barrier to free enterprise by eliminating Ogden’s monopoly American Railroads Steam-powered trains became popular in U.S. in the 1830s The locomotive Tom Thumb was built by Peter Cooper The popularity of trains eventually led to about 30,000 miles of track being laid (by 1860) By 1860 U.S. railroad companies had grown very powerful Railroads allowed manufacturers and farmers to compete with each other in national markets, leading to lower consumer prices Chapter 13 Industrial Growth in the North (1790 - 1860) Section 4 More Technological Advances Messages by Wire Samuel F.B. Morse – invented telegraph – send messages over wires across great distances using pulses of electric current Morse code was the name given to a system of dots and dashes representing each letter of the alphabet Telegraph came into common use after a telegraph reported the news of the Democratic National Convention of 1844 During the 1850s, telegraph lines were strung along railroad tracks New Factories Factory owners shifted from water power to steam power to run machines – caused major changes in nation’s industrial growth – factories could now be located anywhere Northeast remained home to most of nation’s industry Factories moved closer to cities to be near labor source and reduce shipping costs Better Farm Equipment John Deere – built steel plow – made planting easier Cyrus McCormick – mechanical reaper – made harvesting easier and faster Changing Life at Home In the 1850s, women were able to work out of their homes using a machine designed by Isaac Singer (sewing machine) Iceboxes cooled by large blocks of ice allowed people to store fresh food safely (1830s) Iron cookstoves began replacing cooking fires and stone hearths The Transportation Revolution was a period of rapid growth in the a. use of turnpikes to get products to market during the 1800s. b. use of steam engines that powered boats and railroad trains during the late 1700s. c. technological discoveries that improved travel in Britain during the late 1700s. d. speed and convenience of transportation in the United States during the early 1800s. Telegraphs grew in use after a telegraph reported the a. race between the Tom Thumb and a horse-drawn railcar. b. results of the Democratic National Convention of 1844. c. first voyage of the Clermont. d. strike at the Lowell mill in 1836. A mechanical reaper that made harvesting faster and more efficient was designed by a. Eli Whitney. b. Cyrus McCormick. c. John Deere. d. Dr. Rush Nutt. Morse code was the name given to a system a. using a series of short and long electric pulses that represented letters and numbers. b. of hiring entire families to work in factories. c. developed by Robert Fulton for navigators of steamboats. d. using interchangeable parts to make machines. The locomotive Tom Thumb was built by a. Eli Whitney. b. Peter Cooper. c. Tredegar Iron Works. d. the Springfield Armory. In the 1850s more women were able to work for pay in their homes if they owned a machine designed by a. Sarah G. Bagley. b. Isaac Singer. c. Lucy Breckinridge. d. Cyrus McCormick. Samuel F. B. Morse invented a. ferry service. b. the telegraph. c. the automatic rifle. d. the first clock. On August 9, 1807, a. Robert Fulton successfully sent the Clermont up the Hudson River. b. the Tom Thumb proved its power during a race against a horse-drawn railcar. c. Samuel Morse received the message, “What hath God wrought?” d. Eli Whitney first assembled random pieces into a working musket. A device that sends and receives pulses of electrical current through a wire is a a. telegraph. b. spinning jenny. c. textile. d. Lowell system.