BrochureDimaen

advertisement

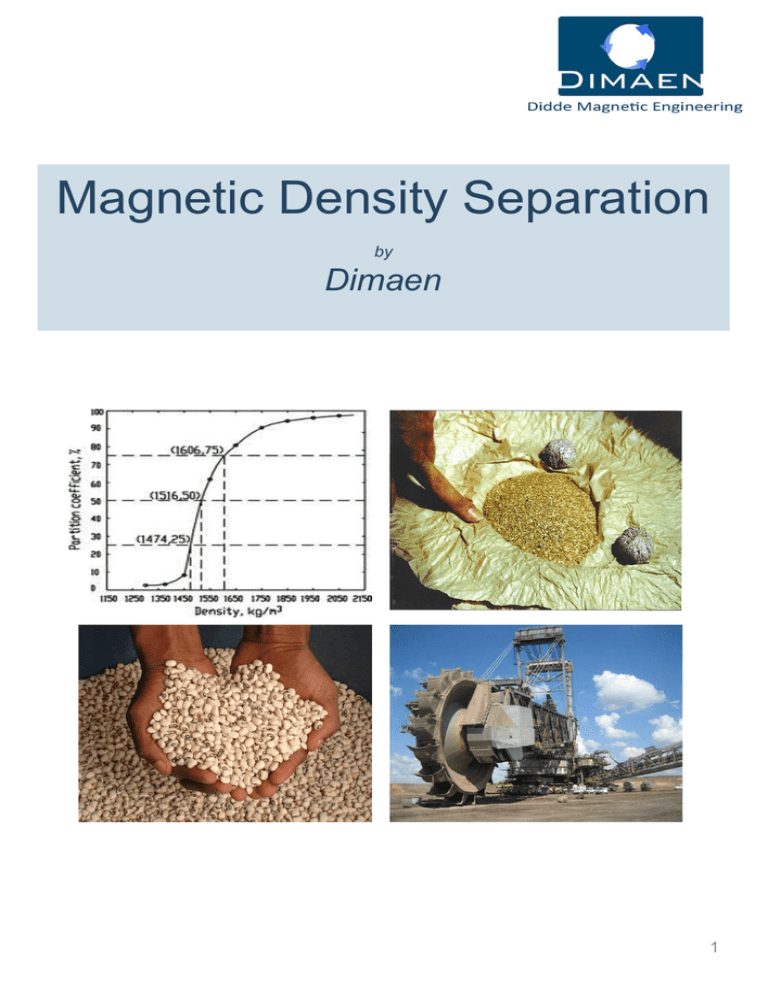

Magnetic Density Separation by Dimaen 1 Table of content Content Page Dimaen – our philosophy 2 MDS – Magnetic Density separation 3 MDS – applications 3 Semi continuous separation 4 Full continuous separation 4 Dimaen Company profile Dimaen is a young startup in magnetic technology including the development, manufacturing, marketing, sales and service of magnetic solutions for a wide variety of businesses. After being present in the magnetic industry for many years Dimaen is starting out as a promising supplier for MDS separation systems. Dimaen is established in a technological partnership with TU Delft. Solution We are specialized in MDS-technology and with this patented revolutionary sorting method it is possible to divide various material mixes in clean separated fractions. With this particular sorting mechanism Dimaen tries to combine industry expertise with innovative technology to deliver the best sorting you need. MDS separation is superior for many applications to known sorting methods in terms of efficiency, speed, costs and footprint. Dimaen can provide a turn-key project for you company, starting with a lab system (proof of technology), which makes it possible to test your process on a small scale. This provides you evidence and comfort about the process which can be scaled to the larger plant version. Quality & Environment It is Dimaen’s strong commitment to meet and even exceed customer's requirements and expectations. Starting with effective communication we build towards a system which is the most effective way to achieve your needs. Striving to achieve the best possible balance between ecological, social and economical needs is part of Dimaen’s quality management process. It is considered as an obligation to provide products and services with the objective of total customer satisfaction. MDS is environmentally friendly while using permanent magnets which allows us to design a system almost without energy consumption. For special needs it will be possible to design a complete system which is off grid for power and water. The magnetic fluid is based on normal water and completely environmental and health friendly. MDS is green technology! Market In a world where resources and labor becomes more expensive efficient separation techniques can be the answer. We can offer larger production systems for example in the recycling industry (urban mining) where all kind of mixtures of plastics and metals can be separated in virtually 100% pure fractions. In the mining industry MDS can be used as a highly efficient system to separate for example diamonds from a mud mixture or to separate precious metal particles from a mixture. A completely different way of separation can be done on a smaller scale. For example to sort seeds by their density which is a strong indicator of their germination. MDS can separate it in multiple fractions in just one step. Not only separation, also monitoring can be done effective based on MDS technology. In this system the input will not be separated into fractions. The separation which will take place in the machine is here monitored by a vision system which output gives a clear view on the contains of a mixture. This system can for example analyze batches of coal for their ash levels. This will clearly indicate the purity of the coal and herewith the price. With our system the customer can analyze in a quick and low cost way. Mission statement It is our goal to improve the customer's efficiency, speed, quality, costs and environmental footprint with regards to particle separation or monitoring with MDS systems by implementing turn-key systems with which these customers will use our technology in a wide range of different applications. 2 Magnetic Density Separation Fundamental research into magnetic fluids spans more than thirty years, in the course of which a number of practical applications have emerged. Magnetic fluids become heavier when exposed to a magnetic field and can thus be used to separate materials of different densities, with lighter materials floating to the surface. However, since practical fluids took a long time to appear on the scene, development was faltering. Raw materials technologist Dr Peter Rem (TuDelft) discovered a new approach, in which separation becomes a viable option for applications like the recycling of plastics and metals, and for refining diamonds. Instead of bulky, energy-hungry electromagnets, the system uses permanent magnets. A patent has been applied for. Technology MDS technology has been proven for some years in laboratory demo models and now MDS is ready to introduce his huge benefits in applications where density separation or density monitoring is currently covered by conventional systems. MDS will make it possible to design smart solutions which are much smaller and will ask for a fraction of the electric power used by conventional systems. This combined with a very stable output and the possibility to make the complete separation to happen in one single step makes this technique a winner for the coming years for many applications. MDS for Recycling Recycling materials like plastics, glass and metal has really taken off in the past few decades. Even so, many of the recycled materials like plastics for instance, cannot be used for their original purpose, because they are not pure enough. They are contaminated with wood chips (car shredding), textile, domestic waste, metals (shredded electronics) and other types of plastics. With MDS these plastics can be separated into pure fractions. MDS for Mining (separation) In view of the predicted diamond shortage, MDS is one of the processes have been proposed recovering <2 mm diamonds which are currently lost in tailings. MDS can be used for a wide range of separation processes where different densities can be used to separate the process. MDS for Mining (monitoring) For example in the coal processing industry MDS can be used in a monitoring process to test samples of the coal for the ash contamination percentage. Due to the difference in density between the coal and the ash it will split in different heights which can be monitored by a special camera. MDS for agricultural seeds Density Separation of seeds increases the quality of a batch of seeds. A novel, alternative method for separating seeds by density is Magnetic Density Separation (MDS). It is also shown that MDS can upgrade germination quality by separating seeds continuously into multiple fractions in a single process step, which saves a significant amount of time and labor compared to current processes. 3 MDS production systems After fundamental research has taken place for the improved magnets Dimaen has combined this improved magnet with the right magnetic fluid and is able to design, manufacture and install a working production system for your needs. The systems can be categorized into 3 main groups. These 3 categories are named: 1) Semi continuous system; 2) Full continuous system; 3) Monitoring system. Semi continuous system This system has a pre processing step of automatic ‘mixing’ the particles with the magnetic liquid. Mixing is a essential step in the process. Particles stacked together or with air bubbles on the surface will not be separated into the right fraction which lowers the quality of the separation into defined fractions. After a flow controller to remove any turbulences, the particles will be moved to the correct height above the magnet. With the laminar flow the particles will flow into the filter, designed for your specific separation needs. Option washing, drying and other post processing steps will be operated manually. The semi continuous system is the most efficient solution for separation of small batches of higher valuable particles. For the agricultural seed separation this would be the first solution to think about. Full continuous system The full continuous system will start with the same feeder and mixing device as the semi continuous system. Biggest deviation is the full automatic filter which will separate the needed fractions and also separates the fractions from the magnetic fluid automatically. After the separation post processing steps can be integrated according to your needs, like cleaning and drying. The full continuous system is the ideal choice for larger quantities of particles which needs to be processed. For the future we will develop this kind of separation systems for customers like the recycling industry and mining industry for large quantities of high quality and low cost separation. Monitoring system The third main group within the MDS systems will be the monitoring system. In this system the end product is not separated into fractions but the height of the particles in monitored by a vision system. The output of the vision system will give detailed information about the density of the different particles. Combined with the correct data this system will give a detailed output of which particles a mixture contains. The monitoring system can be used in different application like testing coal for there ash level, as a indication for the price of the complete batch. 4 Dimaen Europalaan 168 5283 AS Boxtel The Netherlands Tel. +31 411 67 1067 Mob +31 6 22273518 www.dimaen.com 5