Lecture 4

advertisement

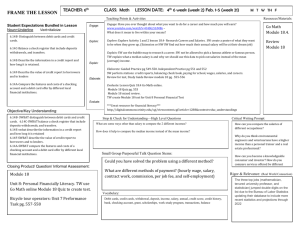

Business Models MGT 709 New Venture Creation Business Model Analysis (Hammermesh) A business model is a “profit engine” or cash generating machine Revenue drivers Cost drivers Investment size Critical success factors Also think about: Value creation/capture/protection Economics of One Unit (EOU) Take one unit (can be a good or service) Selling price per unit less Cost Of Goods Sold per unit Materials Labor =Gross Profit per unit Can you drill down and defend your assumptions? Revenue Types Single stream, multiple streams, interdependent, loss leader Models Subscription (gym, magazine) Volume or unit-based (typical retail) Advertising-based (google, TV) Licensing/syndication (biotech) Transaction fee (realtors, brokers) Fishbone model Fishbone Revenue Model Avg. tuition rate Tuition COB Revenue # of students Student mix Curriculum Rate of return Endowments Reputation Size of endowments Grants Executive education Grant applications Quality of faculty Costs Types Fixed, variable, semi-variable, non-recurring Structures Payroll-centered (direct) Payroll-centered (support) Inventory Space/rent Marketing/advertising Fishbone Cost Model Faculty Salaries (80%) # of faculty Productivity Market rates Faculty mix # of staff Support ratio COB Expenses Support Salaries (10%) Salary rates Operating Expenses (10%) Teaching resources Research resources Investment Size Maximum financing needs (lowest point) Positive cash flow Cash breakeven Cash flow diagram is useful cash balance over time Cash is needed for infrastructure, salary, inventories etc. Critical success factors Which factors have the greatest impact on profitability? Sensitivity analysis Discovery Driven Planning (McGrath) The Reverse Income Statement Total Figures Required profits to add 10% to total profits = $4m Necessary revenues on 10% net profit margin = $40m Allowable costs to deliver 10% sales margin = $36m Per Unit Figures Required unit sales at $160 per unit = 250,000 units Necessary percentage of world market share of OEM unit sales = 25% Allowable costs per unit for 10% sales margin: $144 Building assumptions Assumption 1. Profit margin 2. Revenues 3. Unit selling price 4. Size of OEM market 5. Fixed asset investment to sales 6. Effective production capacity per line 7. Effective life of equipment 8. Average OEM order size 9. Sales calls per OEM order 10. Sales calls per salesperson per day 11. Selling days per year 12. Annual salesperson's salary 13. Containers required per order 14. Shipping cost per container 15. Quality level needed 16. Production days per year 17. Workers per production line per day 18. Annual manufacturing worker's salary 19. Materials costs per disk 20. Packaging costs per 10 disks Measurement 10% of sales $40 million $160 1 million drives 1:1 25 drives per minute 3 years 100 drives 4 calls per order 2 calls per day 250 days $ 100,000 1 container $10,000 50% fewer flaws 348 days 30 per line $50,000 $20 $40 Revisit Income Statement Allowable costs Sales-force salaries $2.0 million Manufacturing salaries $3.0 million Disk materials $5.0 million yen Packaging $1.0 million Shipping $2.5 million Depreciation 13.3 million Allowable administration and overhead costs $9.2 million yen Milestones Each milestone allows for sets of assumptions to be tested and adjusted. Stage 1: Preliminary – salaries, shipping costs, market size, competitor prices Stage 2: Prototyping – materials costs, customer feedback on quality/features Stage 3: Beta testing – price/quality Stage 4: Production – sales/production metrics Expectations for Feasibility Presentations Exercise 3 (p. 178) Exercise 4 (p. 184) Case Study Zipcar