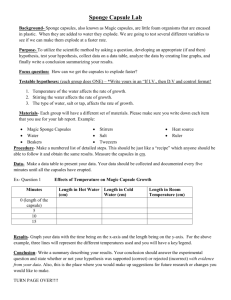

capsules-

advertisement

Capsules are solid dosage forms in which one or more medicinal and/or inert substances are enclosed within a small shell or container generally prepared from a suitable form of gelatin. Depending upon their formulation, the gelatin capsule shells may be hard or soft. Hard Gelatin Capsules The hard gelatin capsule consists of a base or body and a shorter cap, which fits firmly over the base of the capsule . Hard Gelatin Capsules Advantage of Hard gelatin capsules 1. Mask the unpleasant tastes of a drug. 2. Allow powders to be dispensed in an uncompressed form, thus allowing for quicker dissolution and absorption of the drug following oral dosing 3. Have the flexibility which permit a wide prescribing opportunity by the physician in that the pharmacist may prepare capsules containing a single chemical substance or a combination of drugs at the accurate dosage level for the individual patient. 4. Be easier than tablets for some people to swallow. 5. Can alter the release rate of the drug. Disadvantages or limitations include the following : 1. They are subject to the effects of relative humidity and to microbial contamination . 2. They may be difficult for some people to swallow . 3. More expensive (commercially) . The basic empty capsule shells are made from a mixture of gelatin, sugar, and water and are clear, colorless, and essentially tasteless. Colorants may be used to prepare distinctive capsules. Opaque capsules may be prepared by adding an insoluble substance as titanium dioxide to the gelatin mixture. Colored, opaque capsules may be prepared by using both a colorant and the opaque-producing substance. Gelatin, NF, is a product obtained by partial hydrolysis of collagen obtained from the skin, white connective tissue, and bones of animals. It is found in commerce in the form of a fine powder, a coarse powder, shreds, flakes, or sheets Normally, hard gelatin capsules contain between 13 and 16% of moisture. moisture may be absorbed or released by gelatin capsules, depending upon the environmental conditions, in high humidity, capsules absorb moisture and become distorted and lose their rigid shape. but in extreme dryness, some of the moisture normally present in the gelatin capsules may be lost, and the capsules become brittle and crumble. Thus capsules should be stored in areas of low humidity. Gelatin is insoluble in cold water but soluble in hot water, and in gastric fluid where a gelatin capsule rapidly releases its contents. Gelatin, being a protein, is digested and absorbed. Hard gelatin capsule shells are manufactured mechanical dipping of manganese bronze pins of the desired shape and diameter to the desired depth and time into a reservoir of the melted gelatin mixture, maintained at a constant temperature to achieve the desired degree of fluidity. Then the plate and the pins slowly lifted from the gelatin bath and gently dried by a flow of temperature and humidity controlled air Capsule Sizes Empty gelatin capsules are manufactured in various sizes, varying in length, in diameter, and capacity. For human use, empty capsules ranging in size from 000 the largest, to 5 the smallest are commercially available. Preparation of Filled Hard Gelatin Capsules The preparation of filled hard gelatin capsules may be divided into the following steps: 1. Preparing the formulation 2. Selecting the capsule size. 3. Filling the capsule shells. 4. Cleaning and polishing the filled capsules. I. Preparing the formulation Preformulation studies are used to determine if the bulk powders may be blended together as such, or if they require reduction of particle size or processing into formed granules. Dry Powder Milling To achieve uniform drug distribution through out a powder mix, it is advantageous that the density and particle size of the drug and non-drug components are similar. This is achieved by particle size reduction (milling). Diluent Generally, hard gelatin capsules are used to encapsulate between about 65 mg and 1 g of powdered material, including drug and any diluent required. If the dose of the drug to be placed in a single capsule is smaller than 65 mg to produce the proper fill, lactose, microcrystalline cellulose, and pregelatinized starch are common diluents used in capsule filling. But when the amount of drug is large enough to fill a capsule completely, a diluent may not be required. Lubricant a lubricant as 1% Magnesium stearate is utilized to prevent adhesion and facilitate the flow of the powder in capsule filling machine. Glidant The powder mixture or granules must be free-flowing to allow passage from the hopper by the addition of a glidant such as 1% silicon dioxide. Lubricant properties. and Glidant are used to improve filling Wetting agent Addition wetting agents, as sodium lauryl sulfate, in capsule facilitate the wetting of the drug substance by gastrointestinal fluids to enhance associated dissolution, with and overcome water-insoluble the problem lubricant as magnesium stearate which can delay the dissolution of the drug and its absorption. Eutectic mixtures Eutectic mixtures or mixtures that tend to liquefy, may require a diluent or absorbant such as magnesium carbonate, kaolin, or light magnesium oxide to separate physically the interacting agents and to absorb any liquefied material. Liquids Gelatin capsules unsuitable are for the encapsulation of aqueous liquids, because softens the water gelatin to produce distortion of the capsules. However, some liquids such as fixed or volatile oils that do not interfere with the stability of the gelatin shells may be placed in gelatin capsules which then may be sealed to ensure the retention of the liquid (soft gelatin capsules) Semisolids This system can be used for both liquid and solid active ingredients. Mixtures for filling need only be liquid when filled and should be semisolid after being inside the capsules. The materials to be filled must be either thermosoftening or thixotropic in nature to be liquefied by heating or shearing forces using heated hopper with a stirrer and revert to the solid state within the capsule shell. Used for potent drugs to improve uniformity of filling. Used for safely handling toxic drugs to reduce contamination with filling of powders. Granules and Pellets Granules and Pellets are packed in capsules instead of powder to produce modified release patterns. Granules are produced by granulation and are more irregular than pellets which are spherical and produced by microencapsulation technique Capsules within capsules: If one ingredient must be separated from others in the formulation, a small capsule, such as a No. 5, may be filled with one powder and placed into a larger capsule with the remaining ingredients in the formulation. Tablets within capsules: Small tablets are filled into capsules to produce special release forms or to separate incompatible ingredients. This small tablet can be placed inside the capsule following the addition of a small quantity of the powder and the filling completed. Powders Granules Beads Tablets Capsules Pastes Liquids II. SELECTION OF CAPSULE SIZE The selection of capsule size is best done during the development of the formulation, because the amount of inert materials to be employed is dependent upon the size or capacity of the capsule to be selected. The density and compressibility of a powder or a powder mixture will largely determine to what extent it can be packed into a capsule shell. The amount may vary according to the degree of pressure used in filling the capsules. Determination of capsule fill weight To determine the size of capsule to be used or the fill weight for a formulation the following relationship is used: Capsule fill weight = Tapped Bulk Density of Formulation X Capsule Volume III. Filling the capsule shells 1."Punch" Method 2. Hand-Operated Capsule Filling Machines 3. Automatic-Operated Capsule Filling Machines "Punch" Method Used for filling a small number of capsules in the pharmacy, at the prescription counter. The ingredients are triturated to the same particle size and then mixed by geometric dilution. The powder is placed on a powder paper or ointment slab and smoothed with a spatula to a height approximately half the length of the capsule body. The base of the capsule is held vertically and the open end is repeatedly pushed or "punched" into the powder until the capsule is filled; The cap is then replaced to close the capsule. Each filled capsule is weighed using an empty capsule as a counterweight. Powder is added or removed until the correct weight has been placed in the capsule. The filled capsule is tapped so that no air spaces are visible within the contents. hand-operated capsule machines Pharmacists that prepare capsules on a regular or extensive basis may use hand-operated capsule machines. These machines are available in capacities of 24, 96, 100, and 144 capsules. First, the plates are adjusted to hold the capsule bodies in place while the caps are removed all at one time. The caps remain in place in the top of the machine for later use. Then the plates are adjusted again so that the capsule bodies will "drop" into place so that the tops are flush with the working surface of the plate. The formulation powder is poured onto the plate and special spreaders are used to fill the individual capsules. The combs are used to tamp (compress) and pack the powder into the capsules. All of the caps are then returned to the capsule bodies, and the closed capsules are removed from the machine. Automatic-Operated Capsule Filling Machines Machines developed for industrial use can automatically remove the caps from empty capsules, fill the capsules, replace the caps, and clean the outside of the capsules at a rate of up to 165,000 capsules and greater per hour. SEALING of Gelatin capsules In this process, the two capsule parts are sealed with a gelatin or polymer band at the joint of the cap and body. A tamper-resistant seal on hard gelatin capsules was developed in which the contact areas of the cap and body are wetted with a mixture of water and ethanol to soften the gelatin thermally and bonded then at 104° to 113oF to form the seal. CONI-SNAP Hard gelatin capsule A recent innovation in capsule shell design, where the two halves of the capsule shells are enable to be positively joined through locking grooves in the shell walls. The two grooves fit into each other and ensure reliable closing of the filled capsule. Opening of such capsule is difficult with increasing security of the contents of the capsule. IV. Cleaning and polishing the filled capsules Capsules prepared on a small scale or on a large scale may have small amounts of the powder adhering to the outside of the capsules. This powder should be removed before packaging or dispensing to improve the appearance of the capsules and to preserve their quality of being tasteless on administration. On a large scale, many capsule-filling machines are affixed with a cleaning vacuum that removes any extraneous material from the capsules. Another proposed cleaning method is to put the capsules in a container filled with sodium bicarbonate, sugar, or sodium chloride, and gently roll the container. Then the container contents can be poured into a ten-mesh sieve where the "cleaning salt" will pass through the sieve. Soft Gelatin Capsules Soft gelatin capsules (soft elastic gelatin capsules) or (softgels) are prepared from continuous gelatin shells to which glycerin or a polyhydric alcohols such as sorbitol has been added to render gelatin elastic or plastic-like. Soft gelatin capsules may be oblong, elliptical (oval), or spherical round, oval, oblong, tube in shape., They may also be prepared of single or two-tone color, Application of Soft Gelatin Capsules 1. Water immiscible, volatile and nonvolatile liquids such as vegetable and aromatic oils, aromatic and aliphatic hydrocarbons, chlorinated hydrocarbons, ethers, esters, alcohols, and organic acids. 2. Water miscible, nonvolatile liquids such as polyethylene glycols, and nonionic surface active agents as tween 80. 3. Solids may be encapsulated into soft gelatin capsules as solutions in one of the suitable liquid solvents, as suspensions, or as dry powders, granules, or pelletized materials. Liquids which can easily migrate through the capsule shell cannot be encapsulated into soft gelatin capsules. These materials include: Water, above 5%, and low molecular weight water soluble and volatile organic compounds such as alcohols, ketones, acids, amines, and esters. Advantages of Soft Gelatin Capsules 1. They permit liquid medications to become easily portable. 2. Comparing the degree of irritation or ulcerogenic potential of soft gelatin capsule formulations with a tablet formulation, Capsule formulations had a reduced ulcerogenic potential when compared to the tablet formulation. 3. Dose uniformity is optimized, because the drug is dissolved or dispersed in a liquid which is then dosed volumetrically into the capsule accurately. 4. Improve drug stability by resist gaseous diffusion and contain no water, thus protect drugs sensitive to oxidation or hydrolysis on long term storage. 5. Good bioavailability of drugs than from the commercial tablets or capsules, that dissolved or dispersed in a water miscible or oily liquids, thus when the capsule ingested, the drug dispersed as solution or emulsion to give a drug dispersion of high surface area Preparation of Soft Gelatin Capsules In a soft gelatin capsule formulation the medicament is in solution or is dispersed as a fine suspension in either a hydrophilic vehicle or a hydrophobic base. Formulation of soft gelatin capsules There are two main aspects to be considered during the formulation of soft gelatin capsules: The composition of the gelatin shell and the composition of the fill material. Formulation of the gelatin shell The composition of the soft capsule shell consists of two main ingredients: gelatin and a plasticize (e.g. glycerol). Water is used to form the capsule and it may be desirable or even necessary to add other additives such as preservatives, dyes, opacifiers and, rarely, flavours and drugs. Gelatin To produce shells with a greater flexibility than hard gelatin capsules it is necessary to control carefully the viscosity and strength of the gelatin used in production. If the viscosity of aqueous gelatin solution is too low, a thin, low strength shell is produced which has the disadvantage of requiring prolonged drying. If the viscosity of the gelatin solution is too high, a thick film is produced which may be too hard and brittle. also require higher sealing temperatures during manufacture. The mechanical properties of the gelatin shells are controlled by choice of gelatin grade and by adjusting the concentration of plasticizer in the shell. Plasticizers The main plasticizer used for soft gelatin capsules is glycerol. Sorbitol and propylene glycol have also been used but they are normally added in combination with glycerol. Plasticizers are added in relatively large concentrations. The greater the plasticizer content the greater the flexibility of the shell. (0.3-1.0 parts of dry plasticizer to 1 part of dry gelatin). Low ratios 0.3-0.5 are used for oily liquid fills, (0.4-0.6) for oily fills with added surfactant, (0.6-1.0) for water-miscible fills and chewable capsules. Water The demineralized water content of gelatin solution used to produce a soft gelatin capsule shell depends on the viscosity of gelatin used (0.7-1.3 parts of water to each part of dry gelatin), 1: 1 ratio being typical. Preservatives Preservatives are added to prevent mould growth in the gelatin shell. Potassium sorbitate and methyl, ethyl and propyl hydroxybenzoate (methyl-, propylparaben) are common additives. ethyl- and Colours A wide range of colours can be incorporated into soft gelatin shells Water-soluble dyes (synthetic and vegetable), insoluble inorganic and organic pigments and lakes. Opacifiers Titanium dioxide is the most common. It is added in concentrations of about 0-0.5%. Enteric treatment Enteric properties can be imparted to soft gelatin shells by coating with 4% cellulose acetate phthalate. Formulation of the capsule contents Any non-aqueous liquid or powdered solid in suspension can be filled into soft gelatin capsules. It is possible to fill soft gelatin capsules with a very wide range of materials. Suspensions, pastes, drugs in solution in either oils, selfemulsifying oils or water-miscible liquids. Limitations for fill materials Drugs or excipients containing large amounts of water or other gelatin solvents cannot be incorporated. It is not recommended to fill emulsions (whether they be o/w or w/o) since they are unstable and will crack as the water is lost from the shell in the manufacturing process. Surfactants may have a deleterious effect on the capsule seal. Extremes of pH must be avoided. pHs below about 2.5 attack the gelatin leading to hydrolysis and leakage and pHs above about 7.5 have a tanning effect on the gelatin, and affecting the solubility of the shell. Aldehydes must also be avoided since these have a tanning action on the proteins of the gelatin shell. Liquid vehicles Water-immiscible oils or water-miscible liquids. Water-immiscible oils: Either volatile or non-volatile oils, Fixed aromatic vegetable oils, Aliphatic, aromatic and chlorinated hydrocarbons, Liquid ethers and esters. Water-miscible liquids (hydrophilic) Polyols as Polyethylene glycols with low molecular weight (400-600) since they are liquid at ambient temperatures. Alcohols as isopropyl alcohol, polyglycerols, triacetin, glyceryl esters, sorbitan esters, sugar esters and polyglyceryl esters. Propylene glycol and glycerol can be used, but the concentration must be low, (5-10%), in order to prevent migration into the gelatin and softening of the shell. Suspensions The particle size of the solid should be reduced to less than 180 µm to pass through the filling head. Insoluble drugs can be dispersed (with suspending agents and surfactants) in the above vehicles or combinations of vehicles. Suspending agents are added to prevent settling and maintain homogeneity • For oily bases (beeswax, paraffin wax, ethylcellulose and hydrogenated vegetable oil) • For non-oily bases (solid glycol esters as PEG 4000 and PEG 6000). Surfactants as polysorbate 80 (Tween 80) are often added as wetting agent. Caking of suspensions in soft gelatin capsules can be avoided by rheological control of the vehicle. Preparation of Soft Gelatin Capsules Preparation of Soft Gelatin Capsules Soft gelatin capsules may be prepared by: The plate process, using a set of molds to form the capsules. The die processes (rotary or reciprocating processes) more efficient and productive processes the plate process A warm sheet of gelatin (plain or colored) is placed on the bottom plate of the mold. The liquid medication is poured on it. Then a second sheet of the prepared gelatin is carefully laid in place on top of the medication, and the top plate of the mold is put in place. The entire mold is then subjected to a press where pressure is applied to form, fill, and seal the capsules simultaneously. The capsules are then removed and washed with a solvent harmless to the capsules. the rotary die process Liquid gelatin flowing from an overhead tank is formed into two continuous ribbons by the rotary die machine and brought together between twin rotating dies. At the same time, metered fill material is injected between the ribbons at the moment that the dies form pockets of the gelatin ribbons. These pockets of fill-containing gelatin are then sealed by pressure and heat. The soft gelatin capsules may be prepared of single or two-tone color, the latter resulting from the employment of two different colored ribbons of gelatin to form the sides of the capsule. Manufacturing process The reciprocating die process • The reciprocating die process is similar to the rotary process in that ribbons of gelatin are formed and used to • encapsulate the fill, But it differs in that the gelatin ribbons are fed between a set of vertical dies that continually open and close to form • rows of pockets in the gelatin ribbons. These pockets are filled with the medication and are sealed, shaped, and cut out of the film as they progress • through the machinery. As the capsules are cut from the ribbons, they fall into refrigerated tanks which prevent the capsules from adhering to one another. • • • Capsules are usually packaged in glass or in plastic containers Some containing packets of a desiccant to prevent the absorption of excessive moisture by the capsules. Soft capsules have a greater tendency than do hard capsules to soften and adhere to one another, and they must be maintained in a cool, dry place.