coal mining - ES-Emerald(2010

advertisement

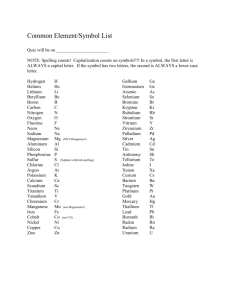

ASSIGNMENT IN EARTH SCIENCE Coal Coal • Coal is a readily combustible black or brownish-black sedimentary rock normally occurring in rock strata in layers or veins called coal beds. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure. Coal is composed primarily of carbon along with variable quantities of other elements, chiefly sulfur, hydrogen, oxygen and nitrogen. Methods of Extraction: I. Surface or Opencast Mining • When coal seams are near the surface • Recovers greater proportion of coal deposit as more coal seams are in the strata • Can cover an area of many square kilometers EQUIPMENT USED COAL MINING 1. Draglines – large excavating machines used to remove the overburden or layers of earth, rock and other material covering a coal seam 2. Electric power shovels – used to remove overburden and load coal 3. Huge bucket wheel excavators – also employed in the overburden removal process 4. Trucks – used to haul both rock and coal from the mine site 5. Sophisticated covered conveyor systems – to deliver coal to nearby preparation plants and eventually on to the customer II. Underground or Deep Mining •When coal seams are too deep underground for opencast mining •2 main methods of underground mining 1. Room-and-pillar – coal deposits are mined by cutting a network of “rooms” into the coal seams and leaving behind “pillars” of coal to support the roof of the mine 2. Longwall mining – involves the full extraction of coal from a section of the seam or “face” using mechanical shearers Coal What is Coal? Coal is a readily combustible black or brownish-black sedimentary rock normally occurring in rock strata in layers or veins called coal beds. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure. Coal is composed primarily of carbon along with variable quantities of other elements, chiefly sulfur, hydrogen, oxygen and nitrogen. Coal begins as layers of plant matter accumulate at the bottom of a body of water. For the process to continue the plant matter must be protected from biodegradation and oxidization, usually by mud or acidic water. The wide shallow seas of the Carboniferous period provided such conditions. This trapped atmospheric carbon in the ground in immense peat bogs that eventually were covered over and deeply buried by sediments under which they metamorphosed into coal. Over time, the chemical and physical properties of the plant remains (believed to mainly have been fern-like species antedating more modern plant and tree species) were changed by geological action to create a solid material. Coal, a fossil fuel, is the largest source of energy for the generation of electricity worldwide, as well as one of the largest worldwide anthropogenic sources of carbon dioxide emissions. Gross carbon dioxide emissions from coal usage are slightly more than those from petroleum and about double the amount from natural gas. Coal is extracted from the ground by mining, either underground or in open pits. Coal Cost of Mining Its very expensive to produce coal. If you want to produce it, you have to spend millions on drills and also pay the costs of your company. Coal Coal Market Value Despite its status as the most 'environmentally incorrect' source of energy, coal provides 25% of the world's energy and generates about half of the electricity in every state in the United States, except California. Coal plays a key role in the production of steel, with approximately 70% of the global steel production depending on coal as a source of energy. And the price of coal has been soaring to record levels. Macquarie Bank expects metallurgical coal to reach an average price of $150 per metric ton in 2008. Citicorp is even more bullish, forecasting that the annual contract price for thermal coal will reach $100 per metric ton in 2008, while the price of metallurgical coal may hit $200 per ton. What's behind the bull market in coal? First, demand for coal is exploding. In addition, in April, China officially announced it would close coal factories, a 125-mile perimeter around the Olympics site of Beijing between July 20 and August 24, 2008, to reduce emissions, pollution, and smog during the Olympic games. Also, Australia, for years the world's leading exporter of coal, has also been suffering from poor weather, which has disrupted coal production and transportation in its crucial coal-producing state of Queensland. Exploding demand combined with supply disruptions adds up to one thing: higher prices for coal. Coal Dangers of Coal Mining Coal dust is also a dangerous explosive. Today, electronic sensors constantly monitor for methane and for Black Damp, a mixture of nitrogen and carbon dioxide that can cause suffocation if sufficiently concentrated. Another invisible hazard is lung disease (pneumoconiosis or “Black Lung”) brought about by breathing coal dust. In every year from 1900 to 1945 more than 1,000 coal miners were killed in mining accidents. In many years there were more than 2,000 deaths, and, as noted above, in just the month of December, 1907, there were more than 3,000 coal-mining deaths. In 1961 there were 293 deaths; in 1981 there were 153, and in 2001 there were 42. It sounds like coal mining has gotten a lot safer, and no doubt it has. But there are also far fewer coal miners in the United States than there were in the first half of the 20th century, and much mining today is done by the less dangerous open-pit method. The effect of these factors on the number of mine deaths is unknown. Suffice it to say that underground coal mining remains one of the most dangerous occupations in America, and it is even more dangerous in less developed countries where safety regulations and enforcement are more lax. Hundreds of miners die in explosions in China each year. The death toll has also been high in Poland and the Ukraine. Manganese Manganese • Manganese is a chemical element, designated by the symbol Mn. It has the atomic number 25. It is found as a free element in nature (often in combination with iron), and in many minerals. As a free element, manganese is a metal with important industrial metal alloy uses, particularly in stainless steels. MANGANESE MINING Manganese ore mining consists of digging tunnels or shafts into the earth to reach buried ore deposits. Initial mining process is similar to coal underground mining. The manganese ore produced from the underground is processed in the mine. Manganese process mining flow chart: Crushing and Screening Plant The crushing and screening plant is used for crushing, hamming and impacting purposes. The plant allows the breakdown or crushing of manganese ore. Crushing plants are static or mobile assemblies containing a range of equipment, such as a prescreener, loading conveyor, intake hopper, magnetic separator, crushing unit (jaw crusher, cone crusher etc.), screens, undersized conveyor and oversized conveyor. Crushing and Screening Plant The purpose of the screen is to separate and grade aggregates into different size fractions. Screening equipment can be used to remove contamination and large materials unsuitable for further processing, or to produce specific aggregate gradings. Screens can be mounted in decks, or placed in series, such that the material passing the first screen is further screened to remove smaller particles. Manganese What is Manganese? Excluding a small circle of technical specialists including metallurgists and chemists, manganese is a little-known element. Nevertheless, it's the fourth most used metal in terms of tonnage, being ranked behind iron, aluminum, and copper. Today nearly 29 million tons of the ore if being mined annually. Manganese is a grayish-white metal. It is the twelfth most abundant element in the earth's crust, but is only rarely found in concentrations high enough to form a manganese ore deposit. Among some 300 minerals containing manganese, only about a dozen are of mining significance. Manganese has numerous applications which impact on our daily lives as consumers. Objects made of steel, portable batteries, and aluminum beverage cans all require manganese for production. In each case manganese plays a vital role in improving the properties of the alloys and compounds involved in each specific application. Manganese is an essential ingredient to iron and steel production. In fact, nearly 95% of the world's total annual production of manganese is directly allocated to the iron and steel industry to purify iron and to make alloys. In alloys, manganese increases the durability and corrosion resistance of iron and steel and makes steel more malleable when forged. Manganese Cost of Mining Mining for minerals is expensive. But it’s well worth it. It is very expensive since there are many expensive things you need to keep an eye on. These things are employees’ salaries, drills, taxes, and equipment. Manganese Manganese Market Value A small group of hi-tech startups is about to take a major chunk out of a $297 billion/year market. Heavy demand for iron ore is back, coming mainly from developing economies like China and India. This has created the biggest bull market for manganese ever in recent years. And, with China's seemingly insatiable hunger for steel expected to continue, it can be assumed that the demand for manganese to go even higher. Analysts have predicted that the steel demand will grow by 2.2 trillion pounds this year. That means huge demands for manganese and huge profits for producers. One producer, BHP Billiton [NYSE: BHP], has already cashed in on the rally. In 2005 share prices increased nearly 40%. Another firm, French producer Eramet [EPA: EUR], has also cashed in on the bull market. Eramet shares have increased 72% in the past 12 months. (Note: Both of these companies also produce several other alloys but have a significant stake in the manganese industry.) Current estimates of world manganese reserves including low grade ore, reach several billion tons. Manganese Dangers of Manganese Mining While there is very little in the literature about criminal or accidental manganese poisoning, manganese ores and their industrial applications give rise to a number of cases of occupational poisoning. The historical background of the condition has already been reviewed in a previous paper (Rodier and Rodier, 1949) but it should be noted that this occupational disease has been recognized since 1837 when Couper of Glasgow observed the first cases among five manganese ore crushers. He described a series of nervous phenomena: muscular weakness, paraplegia, tremor of the extremities, a tendency to lean forward while walking, whispering speech, and salivation. Since then a number of writers have made further observations and recognized manganese as a poison affecting the central nervous system. It is less well known than other metallic poisons. It continues to be rare since only a limited number of workers come in contact with manganese in a dangerous form. The symptoms, which progress as a rule to total disablement, render it one of the most serious occupational hazards. It poses important social problems, as much concerning the rehabilitation of partially incapacitated laborers, as the care of the sick man and his family by the community. Phosphate PHOSPHATE • A phosphate, an inorganic chemical, is a salt of phosphoric acid. In organic chemistry, a phosphate, or organophosphate, is an ester of phosphoric acid. Organic phosphates are important in biochemistry and biogeochemistry or ecology. Inorganic phosphates are mined to obtain phosphorus for use in agriculture and industry.[1][2][3] At elevated temperatures in the solid state, phosphates can condense to form pyrophosphates PHOSPHATE MINING PROCESS OF PHOSPHATE MINING Flow Chart: The process of mining phosphate begins with a dragline that removes the top layer of soil. The phosphate is naturally occurring in a matrix layer of sand, clay and phosphate, which is usually located 15-50 feet below the earth’s surface and is 10 -20 feet thick. The matrix is then transported to a pit where is it mixed with high pressure water guns to create a slurry that can be pumped to a beneficiation plant. Dragline Excavator Once the slurry reaches the plant it then begins the “floatation” or “beneficiation” process which separates the sand and clay from the phosphate rock. This step removes the largest particles, but to recover the sand sized phosphate particles the slurry must be treated further. First, slurry is passed through a hydrocyclone to remove clay. Then sand and sand-sized particles then go through a process that uses water, physical force, and chemicals to separate the sand and phosphate. The clay is deposited in a pond, and the sand is used as fill to restore the mining site. Finally, for the phosphate to be used as water-soluble fertilizer it must be chemically processed. This is completed by mixing the phosphate with sulfuric acid, which forms phosphoric acid that is then used for fertilizer and a byproduct phosphogypsum. PHOSPHATE • The general chemical structure of an organophosphate. Phosphate What is Phosphate? A phosphate, an inorganic chemical, is a salt of phosphoric acid. In organic chemistry, a phosphate, or organophosphate, is an ester of phosphoric acid. Organic phosphates are important in biochemistry and biogeochemistry or ecology. Inorganic phosphates are mined to obtain phosphorus for use in agriculture and industry. At elevated temperatures in the solid state, phosphates can condense to form pyrophosphates. Phosphate Cost of Mining Just like other minerals, Phosphate mining is very expensive. Since mining is a very dangerous work, wages are very costly. Phosphate Phosphate Market Value • The price of phosphate rock rose 700% in 14 months alone. While demand continues to increase, the cost of mining phosphate rock is increasing due to transport in addition to a decline in quality and greater expense of extraction, refinement and environmental management. • In addition to increasing the demand and hence price of phosphate rock, biofuel demand is increasing fertilizer runoff from short-rooted energy crops to pollute waterways. Phosphate Dangers of Phosphate Mining A roof fall was not the greatest danger that miners faced (and still face). That was -- and is -- the danger of the explosion of methane gas. Methane is a natural by-product of the organic processes that took place millions of years ago when coal was formed. In earlier times, safety officials would go in to check the mines before workers entered. THE END !! Submitted by : Geologist : Godwin Gil Industrialist: Chiqui Dizon Economist: Celine Arnado