Week 3 Sr. Design

advertisement

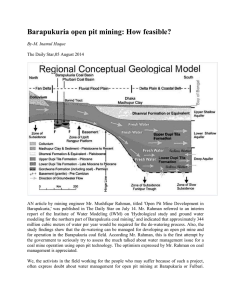

Week 3 Sr. Design DIAMONDS Your Key Finders • Your diamond deposit is extraordinarily large and high grade • Your controlling issues are the ability of the market to adsorb stones and avoiding mining methods that loose tonnage Turning in Work • For Week 2 you were to write up several report sections – Turn those written sections in right away. • Section on Value of Diamonds • Section on Water cost and plan Area Your Write-Up Needs More Work • Workforce – You defined what safety training you would provide – Miners must be tasked trained – training to run a cash register at Walmart is insufficient to cover high voltage electrical work on a jumbo drill • You must address miner workforce training – Your decision on mining method may influence where you will hire your engineers and Sr. professionals – Use this week to get a better write up on these things Work to Do • Determine the approximate number of carets of each color diamond entering the market each year. – For many of the colored stones the Argyle mine in Australia may dictate most the market – For red you probably cannot define a tonnage they are so rare – your find may inevitably make red more like pink in price – Estimate how many carets you can produce • Use this to determine a tonnage production rate for your mine More Calculation Estimates • Estimate the amount of ground of various types you would need to mine to get your production target for the first 40 years • Look at your orebody for the most cost effective, safe, and reliable location to mine to get that 40 year supply • Now look at your target region to see if it suggests particular mining methods List Mining Methods • That yield very high recovery • List approximate recovery rates and costs for each method. – Look at safety and environmental issues raised by each candidate method Start looking at Practicalities of Your Methods • Open pit will be the quickest to start and lowest in cost and probably have the greatest safety. – The land is ranchland – are there reclamation or environmental issues that immediately rule out open pit? – When the Autistic Artisans heard that you were starting a mine by them they gathered around and threw their jewelry in a fire and took a blood oath that they would not be moved or let any of the spawn of Satan cross their land. Then they all went down to Jewelry stores in Cheyenne and spit on all the counters and clerks • How much surface mining can you do if you cannot touch the land of the Autistic Artisans? Another Open Pit Issue • Open pit mining can only mine top down and outward – If production you want to maximize your earnings each year subject to a market constraint require you to select your products open pit may not allow you to select what you mine and when – Is this a problem for you? – Do you have another mining method that does not waste valuable ore and allows you to produce from selected parts of the orebody to hit your market constrained maximums? • Does that method have any environmental or safety faults? Finalize Your Mining Method • Make sure you can explain how your mining method works • You may end up using different mining methods for different parts of the orebody – Make and justify the decision on your mining method • Estimate where you will put mining structures including roads, pits, shafts, slopes as appropriate for your method • Estimate your sequence of what you will mine and when What This Means You Will Have • Suppose you were using open pit and undercut and fill. – On the open pit I would be able to see the final pit or the pit after 40 years • Draft version only – it does not mean you have figured bench heights, road widths, or pit slopes – I would be able to see where your production shafts and slopes would be, the layout of your levels, and where the production panels of the next 40 years are located. – You would be able to tell me what the mining rates and tonnages were each year. Processing • You now have a tonnage to process and a grade for the material you will process – Lay out a more detailed process that includes what equipment you will use in what series and what capacity you will need on each unit. • This means you will have a flow sheet with equipment and capacities • It does not mean that you have done computer simulation to confirm your method and capacities work or that you have prices for your equipment Work Out Your Marketing Plan • What processing and work will you do on site? • What will you ship out? In what form? How will you ship it? • Where will you have your stones cut – or will you sell raw stones? If you sell raw stone to whom will you sell them and where will you ship them for sale? – If you cut your own stones where will you sell? COAL Where You Are At • You will have a 30 to 40 year 3 million tons clean steam coal reserve using room and pillar in the #5 and #6 coal • You will have met coal from #2 as long as economics are favorable • You plan to drop the #7 coal as difficult to market due to BTU • You plan to room and pillar your underground Things to Turn in • Turn in your text you wrote last week – How will you get coal to market and what will shipping cost you. – How much will coal of various types sell for • This weak look at the communities around you. – What is your available work force – What types of consumable supplies such as roof bolts and rock dust are readily available in the area – What services are available in the area as far as rebuild shops for reconditioning and maintaining equipment – Write Up a Report Section on Available Labor Resources and Support Services in the area Things to Finish • Obviously finish your computer model of your reserve – Then define minable and unminable areas • You already did most of this except that without the model you could not eliminate areas where coal was too thin or the coal was in a remote block not worth going after – Present your coal thickness contours and minable areas • Re-estimate your reserves and life in #5 and #6 Examine And Defend Your Decisions from an Economics Standpoint • You suggested blending #5 and #6 – #5 coal is often less than 1% sulfur and around 0.1% chlorine – #6 coal is high sulfur and 0.5% chlorine – Your market studies suggested that low chlorine or low sulfur might have a premium which obviously you will loose in blending • Explain and show estimates of coal value if the two seams blend • Explain and show mining and processing cost estimates for blending versus not blending • Can you defend that decision from an economics standpoint? You Proposed Dropping #7 • Number 7 was a surface mine reserve – You indicated a potential premium for low chlorine coal and #7 is low chlorine • What would #7 coal bring if you mined it? (you did indicate it was weak on BTU 10,100/lb for coal you reject and 10,900/lb for coal you will mine) – You indicated you would have to reclaim prime farm land if you mined #7 – what would that cost you per ton of coal if you stripped #7 – You indicated you would have to buy a separate fleet of equipment to mine #7. What would your cost per ton be to mine #7 given the stripping ratio and the extra equipment Continuing Your #7 Decision • Profit per ton #7 = value/ton – mining cost/ton – reclamation cost per ton • Profit per ton #6 = value/ton – mining cost per ton • Can you show that #6 coal is more lucrative than #7 coal? – If not is there any compelling technical reason to drop the reserve of #7 coal? Fine Tuning Your Mine Layout • Your mining layout plans heavily on east-west mains that will intersect the fault – Because of the pressure in the #5 coal channel there is a good amount of water in the fault • How will you go through the fault? – You found the fault to be a scissor fault (actually I stole the scissor fault from Wabash mine. It is not a unique in the world of coal feature) • Do you plan on sloping your mains up or down to cross the fault? • Are you going to try to hit it at the pivot point • Where do you need drilling to confirm your fault crossing if you are going to aim at the pivot point – (provide requests by Wednesday at 3:00 if you need them) Start Working Up Your Rock Mechanics • Your mine layout is east west and north-south. The principle in-situ stress is at an angle to this orientation – Indicate your target entry width for main, submains, and panels – Explain how this will impact roof span stability, formation of cutters, and other such roof fall issues • Defend your explanations with rock mechanics – Did this make you change your mind on layout? Why? What does it look like now? Rock Mechanics • Use Rock Mechanics Models to show – What kind and length of roof bolts you should use – What kind of spacing should be needed – Show that the roof span will be stable over the worst case (the diagonal over a cross cut) More Rock Mechanics • Where coal strength dictates pillar size you determined the Holland formula to be the way to size pillars – Size your #2 pillars (sandstone floor) • Explain your pillar sizes and safety factors for – Mains – Submains – Panels More Rock Mechanics • Your #5 coal seam has 5ft of underclay – Using Holland-Grady methods what size pillars would you use • For Mains • For Submains • For Panels More Rock Mechanics • Your #6 coal has about 1 ft of underclay – Is this a Holland Formula or a Holland Grady Situation? – What size pillars do you propose • For Mains • For Submains • For Panels Model Your Interburden • Develop contours for the inner burden between the #6 and #5 coal seams • Develop contours for the inner burden between the #5 and #2 coal seams • Identify areas of interaction risk – Explain your plans for dealing with seam interaction – Are there areas where you do not believe you can mine certain seams together – What does that do to your reserve estimates? Draft Mine Layouts • Show draft mine layouts for each seam including showing how you are carving out areas you believed to be non-minable. COPPER GOLD Things to Finish Up • Get your tonnage and geologic model of your different types of ore done Work with Text • Write a Section on Historic Copper, Gold and Silver Prices – What drove past price cycles – What are those historic prices on an inflation adjusted basis – What do you predict for High, Low, and Expected Prices • Why – Be sure to provide proper references to your sources More Writing • Write a Section on Shipping Product to Market – (it appears likely you will leach-electrowin and produce flotation concentrates on site) – Where will you ship your copper concentrates • How will you ship them • What will it cost to ship them? – Where will you ship electrowon copper? • How will you ship it? • What will it cost to ship it to market? – You may have precious metal concentrates. • Where will you ship it for further processing? • How will you ship it • What will it cost to ship it to market • What will you have to do to roads (or railroads) to make them able to handle the traffic you are proposing? – What will that cost? • As with all section writing be sure to document your sources More Writing • Write a section on the climate of the area and how you expect that will impact or interact with open pit mining or the floatation and leaching operations you envision. Start Sizing Up Your Open Pit Mine • Use your initial cost data for mining and processing costs and recoveries and run Economic Planner to get an open pit. – Your geologic tonnage was 1.4 billion metric tons – What was your open pit minable tonnage? – When you made that first run with economic planner you had to make all sorts of wild guesses at numbers costs and recoveries • Use your map of “which of my data was crappy or a SWAG (silly wild-ass guess) to start trying to get better numbers. Use Your First Pass Ultimate Pit • What mine life and production rate does the open pit minable tonnage suggest – (Last week you made an estimate based on geologic reserve) – With a preliminary mine size make an initial estimate of your required manpower needs • With these parameters pick a truck and loader fleet – Try two or three fleets with about a 2 mile haul (one way) with a 10% grade for 1.5 miles – Which of your truck fleets yields the lowest cost per ton – (You will likely do this using FPC) With Your Truck Fleet In Hand • What does this suggest about bench height, bench width, and road width. – Get estimates of your pit slopes if your equipment controls. • Geologic Constraints on Over-all Pit Slope (over-all pit slope is not a toe to crest slope on a bench which you can make at 70 degrees) – Your country rock and types 1 and 2 will stand at 60 degrees overall pit slope – Alt types 3 and 4 will stand at 50 degrees – Alt type 5 will stand at 42 degrees – Alt type 6 will stand at 37 degrees – A fracture system strikes 45 degrees east of north and dips and 47 degrees. If you daylight these fractures with an over-all pit slope the side of your pit will slide in. Use Your Initial Guess Manpower Needs • Start evaluating the area for its ability to meet your manpower needs – You indicated that you wanted a local labor for from a county with 2,000 people and about 6% unemployment – Looking at your demographics and existing industry in the area is your manpower pool reasonable and adequate? – What kind of training would be needed? Continuing Work on Your Processing • This week you will try to define exactly how you will process your ore to recover what – You have been working with a concept of continuous leaching • If you stay with it you should explain what equipment you need, how it will work, and what capacity you are looking to have – You will be estimating recovery from the processes – You will be estimating costs for the processes Work on Processing • Your Oxide zone – How many tons do you have? – Copper is acid soluble so a leach process will work – Gold is free milling and metallic so it will respond to gravity concentration after grinding or some sort of cyanide leach (cyanide leach for gold and acid copper leach are very different in pH requirements and can’t be done simultaneously) – Your silver is 50% metallic silver, 25% in a metallic mixture with gold, and 25% substituted traces in copper minerals – how will you recover that? More Processing • Primary Sulfide Zones – Zones 1 and 2 • Cu minerals 70% Chalcopyrite 30% Bornite – Both minerals respond well to flotation – Chalcopyrite will leach very slowly with ferric iron under acid conditions. Bacteria are usually needed to produce the ferric iron – Bornite releases a little copper faster initially but then slows down to chalcopyrite pace – Most sulfide leaches for primary copper are dump leaches with 10 to 15% recovery. Part of the reason is that building vessels for such a slow process is usually not economically attractive • Ag is 37.5% in Argentite, 37.5% in Acanthite, 12.5% substituted in copper minerals, and 12.5% in mixture with the metallic gold – Zone 2 Gold is metallic, but 50% is encapsulated in pyrite – Zone 1 Gold is metallic and 50% encapsulated in pyrite but there is enough “preg robbing carbon” to take up all the gold released by leaching 5 times over. More on Processing • You have a secondary enrichment zone (3) – Copper is split 50% to Chalcocite and 50% to Covellite • Both minerals respond well to floatation • Both Cu minerals will leach with ferric ion under acid conditions, but the leaching reactions are much faster (5X or better) than Chalcopyrite and Bornite – Ag is 50% Acanthite, 25% Argentite, 12.5% substituted in Cu minerals and 12.5% mixed with gold – Au is free milling and metallic so that both gravity and leaching methods may be used Transition Zones • Zone 5 is 50% like zone 6 oxide and 50% like zone 4 secondary enrichment • Zone 3 is 50% like zone 2 primary sulfide and 50% like 4 secondary enrichment.