Powerpoint - New River Kinematics

Objective Read World

Uncertainty Analysis

Tim Nielsen Scott Sandwith

CMSC 2003 July 21-25 2003

Introduction

Confidently optimize production processes against their requirements

Inputs vs. Outputs

Need to simulate process performance to optimize accuracy, speed, and costs

Need reliable (easy to understand) uncertainty estimates for complex 3D measurements on the factory floor

Need to estimate the benefits of combining measurement systems

Common Type Network (n Trackers)

Hybrid Type Network (Scanners + Trackers etc.)

Need real-time (easy to understand) feedback on measurement system performance

Need traceable measurement uncertainty for each assembly

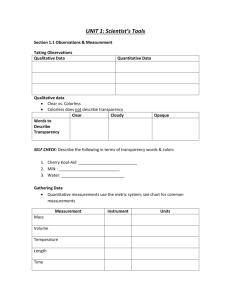

Process Description

Inputs

Object Characteristics

(e.g., Volume, Surface)

Expected Tolerances

Instrument Types and

Number of Stations

Cycle Time

Measurement Constraints

(e.g., line-of-sight, targeting the actual critical features)

Outputs

GUM Compliant

Uncertainty Estimates of

Feature Measurements

Measurement Plan

Number of Instruments

(Stations)

Types of Instrument

Instrument Placement

Targeting Requirements

Network/Orientation

Requirements

Transform vs. Bundle

Number of Common Pts

Closure

Analysis Dependencies

Background: Uncertainty

Guide to Uncertainty in Measurement (GUM)

ISO way to express uncertainty in measurement

Error and Uncertainty are not the same

Quantify components of Uncertainty

Type A vs. B depends on the estimation method

A = Statistical Methods (e.g., Monte Carlo, 1 st -order Partials)

B = Other means (e.g., measurements, experience, specs)

Random vs. Systematic Effects (e.g., Noise vs. Scale)

Both are components estimated with Type A or B methods

Uncertainty Estimates can contain Type A & B methods

GUM mandates uncertainty statements in order to provide traceability for measurement results

A measurement result is complete only when accompanied by a quantitative statement of its uncertainty 1

1 - Taylor and Kuyatt, 1994: NIST TN/1297

Background: Uncertainty

Specifications

Instrument specifications are not representative of the results from actual use of the instrument in a network

3D Measurement Networks

1 Instrument + References

1 Instrument in multiple locations + References

n Instruments (types) + References

Application of 3D Measurement Systems

Real use multiple stations and different instruments in the same network

Quantify coordinate data uncertainty fields in a network

Practical methods to estimate the uncertainty of specific systems

Combining measurement systems

Combining measurement uncertainties

Results need to in an easy to understand and meaningful format

Monte Carlo

What: Non-linear statistical technique

Why: Difficult problems and expensive to state or solve

When: Consequences are expensive

How:

List of possible conditions (where the activity being studied is to large or complex to be easily stated)

Random numbers (from estimates of each measured component)

Model of Network … interactions

Large number of solution are run

Statistical inferences are drawn

Monte Carlo technique was developed during World War II in Los Alamos for the atom bomb project

Modeling

Models

Instruments

Axes

Angles

Ranging

Offsets

Joins

Measurements

Angles ppm

Ranges ppm + offset

Confidence

Wing to Body Join

Application

Inputs

CAD Model includes Features,

Relationships, Tolerances

Sweep, Dihedral, Incidence

Scanners, Trackers, Local

GPS, Robotics, Gap

Measurement Devices

Production Measurement +

Analysis < 3 minutes

Aluminum Surface

Targeted and Pre-measured

Assembly Interface Features

Transfer critical object control to continuously visible features

Outputs

Surface: 0.080” @ 2

Features: 0.004” @ 2

2 Scanners + Local GPS +

GAP Measurement Tool

Optimized Instrument Location

Bundle Local GPS and

Transfer to (11) Common Pts

Local GPS updates at 2 Hz

Aerodynamically matched orientation within process uncertainty

Application

Outputs

Outputs

Results

Results

Conclusions

Acknowledgements

John Palmateer (Boeing)