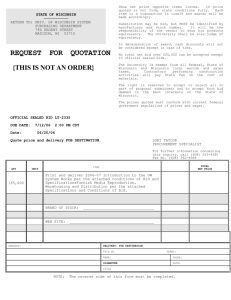

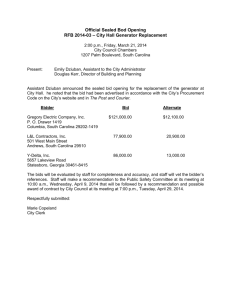

16-5602 Request for bid package

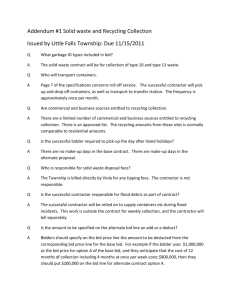

advertisement