Diapositiva 1 - De Molli Giancarlo Industrie Spa

advertisement

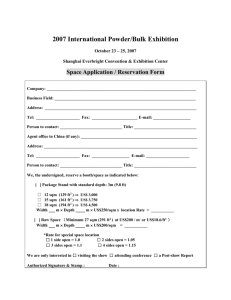

experiences, technologies and innovation since 1948 Castronno, October 3rd 2012 AGENDA • Who we are • Our Numbers • An Overview • Products • Clients 2 WHO WE ARE OUR NUMBERS HISTORY AND PROFILE MISSION PRODUCTS AN OVERVIEW VISION STRENGTHS CLIENTS CHRONICLE From a craft-made reality... Giancarlo De Molli Industries S.p.a. was founded in 1948 as a simple artisanal enterprise dealing with the production of tools. The founder, Giancarlo De Molli, immediately knew how to combine traditional values of the "know how" experience with the great potential of cutting edge technology. In 1964 the production of hinges for motor vehicles began, starting with hot steel forming. In the late '60s, De Molli Giancarlo Industrie S.p.a. acquires the first electric induction furnace that will revolutionize forever its method of industrial production. 3 WHO WE ARE OUR NUMBERS HISTORY AND PROFILE MISSION PRODUCTS AN OVERVIEW VISION STRENGTHS CLIENTS CHRONICLE ...to the market leadership Today, Giancarlo De Molli Industrie S.p.a. holds the leadership in hot and cold steel and aluminium manufacturing and forming, using mechanical and hydraulic presses, induction furnaces and other specific tools. Current size and importance are the result of a steady growth in every field of activity. As a pioneer and a visionary, Giancarlo De Molli's values are now imprinted in our everyday activities. 4 WHO WE ARE OUR NUMBERS HISTORY AND PROFILE MISSION AN OVERVIEW VISION STRENGTHS PRODUCTS CLIENTS CHRONICLE MISSION "To develop, design and produce the best systems and innovative mechanisms for motor vehicles and industry through constant attention to cutting edge technology and innovation." 5 WHO WE ARE OUR NUMBERS HISTORY AND PROFILE MISSION AN OVERVIEW VISION STRENGTHS PRODUCTS CLIENTS CHRONICLE VISION "To constantly develop distinctive know-how that could enable us at any time to design and offer to the market any products for any need, drastically reducing delivery time." Today, after more than 60 years, this "vision" is so ingrained in those who are continuing the job that the impressive results are before our very eyes. 6 WHO WE ARE OUR NUMBERS HISTORY AND PROFILE MISSION AN OVERVIEW VISION STRENGTHS PRODUCTS CLIENTS CHRONICLE Quality Innovation Autonomy Planning Flexibility Production capacity Satisfaction Punctuality 7 WHO WE ARE OUR NUMBERS HISTORY AND PROFILE MISSION PRODUCTS AN OVERVIEW VISION STRENGTHS CLIENTS CHRONICLE Diversified production capacity: - Design and construction of equipment - Hot and cold steel, aluminium, alloys and plastics manufacturing and forming - All types of manufacturing - Automatically controls and assemblies Complete independence and autonomy: production cycle is carried out entirely within our factories, out of after market reality and without having recourse to subcontractors. GROWTH VISION RESEARCH Distinct planning: distinctive know-how and creative capacity, also for the production of complete mechanisms designed for the first implant. STRATEGY MARKETING TEAM INNOVATION 8 WHO WE ARE OUR NUMBERS HISTORY AND PROFILE MISSION AN OVERVIEW VISION STRENGTHS PRODUCTS CLIENTS CHRONICLE Flexibility: we constantly invest in research and development and in human resources, thinking to the quality of the people as our best resourse. Quality and Innovation: we hold over 10 patents in all industry fields and we continue to deposit them continuously. FLEXIBILITY QUALITY DEVELOPMENT Attention to client’s needs: STRATEGY SATISFACTION with a single goal in our activities: its total satisfaction. PATENTS PUNCTUALITY Punctuality: we boast really short time delivery. 9 WHO WE ARE OUR NUMBERS HISTORY AND PROFILE MISSION PRODUCTS AN OVERVIEW VISION STRENGTHS CLIENTS CHRONICLE 1948 – Giancarlo De Molli Industrie S.p.a. establishment as a tool factory; 1958 – Construction of the first warehouse with a molding department; 1964 – Production implementation of hinges for automobiles (Alfa Romeo); 1978 – Realization of definitive operating office and forging department creation; 1982 – Introduction of the first printing presses in partial replacement of hammers; 1988 – Production start of cold forged materials and cutting up; 1994 – Change in corporate and organizational set up and activity expansion towards the new electric and railway businesses; 2000 – Introduction of robotics in production; 2002 – Creation of the stainless steel line for isothermal vehicles; 2006 – Development and creation of products for construction and architecture fields; 2008 – Optimization of the lines for alloys molding and processing; 2009 – Patents registration for mechanisms using non-metallic materials 10 WHO WE ARE PLANTS TOOLS OUR NUMBERS MATERIALS AN OVERVIEW SALES PRODUCTS CLIENTS COVERAGE PRODUCTION UNITS The company is located in a geographically strategic position in the middle of one of the most industrialized European areas. Castronno Plant: 60,000 sqm, of which 15,000 sqm are covered Brunello Plant: 3.000 sqm 11 WHO WE ARE PLANTS TOOLS OUR NUMBERS SALES MATERIALS PRODUCTS AN OVERVIEW CLIENTS COVERAGE PRODUCTION UNITS EVOLUTION 1956: First production plant (540 sqm). 1958: Production expansion and hot forming department construction (670 sqm). 1960: Construction of office and services buildings with machining and tooling department attached (900 sqm). 1999: Construction of a new shed used as machining workplace and storage, and relocation of the old engineering department in order to free the building with a view to expand operating offices (2300 sqm). 2000: Building an extension for machining department (1150 sqm). 2001: Building an extension for hot forming department (330 sqm). 2012 2011 1958 1999 2008 1960 1956 2000 1958 2001 2008: Construction of cold forming department and raw materials and finished products storage (2300 sqm). 2011: Finished, semi-finished and rough goods warehouse expansion (3400 sqm). 2012: Large finished goods and special orders warehouse expansion (2300 sqm). 12 WHO WE ARE PLANTS TOOLS OUR NUMBERS MATERIALS AN OVERVIEW PRODUCTS CLIENTS COVERAGE SALES • • • • • • Hydraulic and mechanical presses up to 6,000 tons; Robotized systems; Manufacturing with transfer and CNC machines of all types; Systems and automations for automatic assembly; Advanced information systems for management, design and production; Testing and quick prototyping 13 WHO WE ARE PLANTS TOOLS OUR NUMBERS MATERIALS AN OVERVIEW SALES PRODUCTS CLIENTS COVERAGE We print, work and assemble, every day, all kinds of rolled steel, aluminum alloys, copper and other metals in order to produce hinges and other mechanisms for both the original equipment and the aftermarket. We provide our customers with finished products and mechanisms, yet ready for line assembling, with heat and surface treatments required by drawings and specifications. 14 WHO WE ARE PLANTS TOOLS OUR NUMBERS MATERIALS 1990 1991 1992 1993 1994 1995 1996 1997 AN OVERVIEW SALES PRODUCTS CLIENTS COVERAGE 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 15 WHO WE ARE PLANTS TOOLS OUR NUMBERS MATERIALS AN OVERVIEW SALES PRODUCTS CLIENTS COVERAGE SALES BY PRODUCT FAMILY 16 WHO WE ARE PLANTS TOOLS OUR NUMBERS MATERIALS AN OVERVIEW SALES PRODUCTS CLIENTS COVERAGE “PRODUCTS THAT COVER ALL ROADS” Road transport and freight traffic vehicles Hinges, components and mechanisms for trucks, commercial vehicles and cars. 100% of trucks manufactured in Italy are assembled with De Molli Giancarlo Industrie S.p.a. hinges. 17 WHO WE ARE PLANTS TOOLS OUR NUMBERS MATERIALS AN OVERVIEW SALES PRODUCTS CLIENTS COVERAGE “PRODUCTS THAT CHANGE IN SAFETY” Rail transport Switches linkage, switches stoppers and clamps. 50% of Italian railway switches is driven by systems designed and built by Giancarlo De Molli Industrie S.p.a. 18 WHO WE ARE PLANTS TOOLS OUR NUMBERS MATERIALS AN OVERVIEW SALES PRODUCTS CLIENTS COVERAGE “PRODUCTS THAT MOVE ENERGY” Energy transport Terminal blocks for medium and high voltage. In Italy, 1 pylon every 10 is assembled with De Molli Giancarlo Industrie S.p.a. components. 19 20 WHO WE ARE LABORATORIES OUR NUMBERS R&D TEST AN OVERVIEW TECHNOLOGIES PRODUCTS CUSTOMIZATIONS CLIENTS CERTIFICATIONS WHAT WE DO: • All types of hardness tests on metals and synthetic materials; • Vickers microhardness tests; • Chemical analysis to determine the composition of materials by spectrometer; • Tests and acid attacks to perform micrographs and macrographs; • Microscope analysis with camera for micrographs recording; • Three-dimensional reliefs using motorized Mitutoyo 3D measuring machine; • Salt spray testing in order to check corrosion resistance; • Tensile strenght tests (with 3 machines) with the possibility of applying loads from 0 to 600,000 N and compression; • Testing implementation on resistance to static and dynamic loads of the prototypes through design and construction of special benches 21 WHO WE ARE LABORATORIES OUR NUMBERS R&D TEST AN OVERVIEW TECHNOLOGIES PRODUCTS CUSTOMIZATIONS CLIENTS CERTIFICATIONS PROJECTS Design, combined with research and development, characterizes all of our products. The R&D department is made up and run by highly qualified engineers that, starting from mathematical models or a specific design, are able, also with the assistance of CAD centers, to develop and manage the entire process. We carry out projects developed on internal specifications, but we can also build, according to specific customer requirements, any kind of product, providing co-design and coengineering services. This philosophy has enabled us to register several patents in several industrial fields, whether properties or shared with customers 22 WHO WE ARE LABORATORIES OUR NUMBERS R&D TEST AN OVERVIEW TECHNOLOGIES PRODUCTS CUSTOMIZATIONS CLIENTS CERTIFICATIONS PROCESSES OPTIMIZATION We perform a continuous production monitoring through the use of techniques of statistical analysis. We look always to the customer satisfaction respecting all the PPM imposed targets. Constant process monitoring allows us to improve the production and become more competitive. Our focus on continuous improvement leads us to do more and more automatic controls, allowing us to certify 100% of the critical features of each product. 23 WHO WE ARE LABORATORIES OUR NUMBERS R&D TEST AN OVERVIEW TECHNOLOGIES PRODUCTS CUSTOMIZATIONS CLIENTS CERTIFICATIONS TEST Our equipments include high precision detection tools, electronic control devices for production and simulation. Our testing department is able to both self-certify our products and obtain the more complex approvals (Iveco, Ferrari, IMQ, RFI, Terna, Enel, Telecom). 24 WHO WE ARE LABORATORIES OUR NUMBERS R&D TEST AN OVERVIEW TECHNOLOGIES PRODUCTS CUSTOMIZATIONS CLIENTS CERTIFICATIONS WE ARE FLEXIBLE We use the latest cutting edge technology for prototypes and serial production, as well as the self-construction of molds, equipment and dedicated machine tools. Our high flexibility allows us, without any problem, to deal with both niche and larger volumes productions. 25 WHO WE ARE LABORATORIES OUR NUMBERS R&D TEST AN OVERVIEW TECHNOLOGIES PRODUCTS CUSTOMIZATIONS CLIENTS CERTIFICATIONS MEET EVERY NEED We have developed a full ability to design and produce according to customer specifications, or simply starting from an idea or particular needs. Our best features are flexibility, speed and innovation, which together provide us with the opportunity to realize industrialization and prototyping, in a few weeks work, starting from 3D models, 2D drawings or samples to tridimensionally detect. 26 WHO WE ARE LABORATORIES OUR NUMBERS R&D TEST AN OVERVIEW TECHNOLOGIES PRODUCTS CUSTOMIZATIONS CLIENTS CERTIFICATIONS OUR CERIFICATIONS Our need to be professionals in every area of our production has led us to specialize our technicians in various fields, through specific courses for welding and non-destructive testing. Our philosophy of "continuous improvement" to all manufacturing processes has allowed us to get all the most important quality certifications. The property and the craftsmen work daily towards a common goal: safety. Professionals and consultants also take regular educational and awareness class in full compliance with in force law. 27 WHO WE ARE FOCUS OUR NUMBERS AUTOMOTIVE AN OVERVIEW ISOTHERMAL VEHICLES CONSUMER PRODUCTS CLIENTS OTHER PROJECTS PRODUCTION We hold the Italian leadership in hot and cold manufacturing and forming of alloy steel and aluminium, by means of mechanical and hydraulic presses, induction furnaces and related tools, in addition to cold forming of all types of metal sheet. Besides we perform: - machining and stock removal on work benches tooled up with modern anthropomorphous robots; - assembly and automated control with self designed and self built machines. 28 WHO WE ARE FOCUS OUR NUMBERS AUTOMOTIVE AN OVERVIEW ISOTHERMAL VEHICLES CONSUMER PRODUCTS CLIENTS OTHER PROJECTS “PRODUCTS RUSHING AT 300 km/h” Automotive We are suppliers for leading car manufacturers, for whom we constantly develop and produce hinges for doors, hoods and trunks. 29 WHO WE ARE FOCUS OUR NUMBERS AUTOMOTIVE AN OVERVIEW ISOTHERMAL VEHICLES CONSUMER PRODUCTS CLIENTS OTHER PROJECTS “PRODUCTS THAT REACH - 40° C” Road transport / Isothermal vehicles We are suppliers for leading commercial vehicles manufacturers, for whom we constantly develop and produce hinges and latches for isothermal vehicles. An effective example is embodied by NoGuide: an innovative hinge without a guide for external walls and floor. 30 WHO WE ARE FOCUS OUR NUMBERS AUTOMOTIVE AN OVERVIEW ISOTHERMAL VEHICLES CONSUMER PRODUCTS CLIENTS OTHER PROJECTS “PRODUCTS OPENED FOR HOUSE” We design and manufacture new products for applications in architecture, interior finished, construction and appliances. Today our greatest challenge is to put to use of these fields all our expertise. In particular, our hinges for refrigerators with patented systems for closing retarders offer solutions of practical use and enhance at the same time the design of the door. 31 WHO WE ARE FOCUS OUR NUMBERS AUTOMOTIVE AN OVERVIEW ISOTHERMAL VEHICLES CONSUMER PRODUCTS CLIENTS OTHER PROJECTS “OUR PRODUCTS HAVE BEEN LAUNCHED IN SPACE” EuroMir Space Project Since 1995 we played an active role in this project and, much to our satisfaction, all the components we designed and made successfully led to the best result of the Project. 32 WHO WE ARE OUR NUMBERS AN OVERVIEW PRODUCTS CLIENTS 33 CONTACTS Registered & Operating Office: Via S. Alessandro, 10 – Castronno (VA) Operating Office: Via Campo di Maggio, 26 – Brunello (VA) Web Site: www.demollispa.it E-mail: info@demollispa.it Tel: +39 0332 892146 Fax: +39 0332 893791 34