Management Accounting - California State University, Sacramento

advertisement

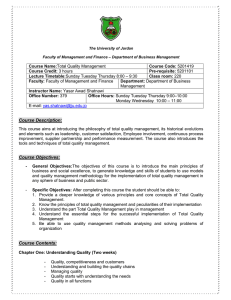

Management Accounting: A Road of Discovery Management Accounting: A Road of Discovery James T. Mackey Michael F. Thomas Presentations by: Roderick S. Barclay Texas A&M University - Commerce James T. Mackey California State University - Sacramento © 2000 South-Western College Publishing Chapter 11 How do we begin the improvement process? Total quality management and continuous improvement Key Learning Objectives 1.Discuss total quality management’s three critical success factors of quality, service, and cost. 2.Define the four quality costs and create a cost of quality report. 3. Explain how to identify valueadded and nonvalue-added activities, and how continuous improvement with kaizen costing supports TQM. 4. Calculate the inefficiency and cost created by nonvalue-added activities. 5. Prepare a fishbone diagram and Pareto chart, and discuss the need for 2nd generation ABC in eliminating quality problems. 6. Identify ways to motivate a TQM mentality. The Objective of Good Management The objective is to maintain and add value to the enterprise. As competition increases, we can increase value by decreasing our costs or differentiating products to add greater customer value. The only truly sustainable competitive advantage is the ability to learn and improve faster than the competition. We want to do things that add value for the marketplace and do these things as efficiently as possible. Part II Definition of Quality — Measuring value created in the eyes of the customer Quality of Design Quality of design is the fit between the customers wants and the goods or services we provide. This means we design products with customers in mind. For example, both the Geo and the Mercedes are quality products but they may not both be quality designs for the same customer. Total Quality Management (TQM) This is a philosophy that focuses on Better product quality (Quality of Conformance). Commitment to customer service (Service). Minimize total costs (Cost). Linking Value to Operational Conformance Quality of Conformance means the product meets its specifications. It has the characteristics the company promises. Service means the company does what it’s supposed to do for the customer. Cost for the customer means all costs incurred by the product throughout the customer’s value chain. A value-focused strategy must consider all three because only current costs and revenues are measured. Value is determined by both current and future cashflows. Nonfinancial measures are lead indicators of future cashflows Part III The Role of Management Accounting in TQM Management Accounting’s Role in TQM Influence change by measuring the costs of current quality activities. Determine the activities adding value to our products (or services) AND THOSE NOT ADDING VALUE. Provide relevant cost information for proposed changes. Monitor and report the financial impact of quality programs. Changing the Corporate Culture Use Cost of Quality (COQ) reporting. The objectives of COQ reports are: Changing the corporate culture. Reporting the money spent on quality failures. Identifying the cost of quality activities. Identifying the relationships between conformance costs and nonconformance costs. Tracking the changes over time. Total Quality Management vs. Traditional Management Conformance The Traditional View is that as conformance costs increase, the nonconformance cost savings decrease. Therefore at some point increasing spending on quality is not justified. The TQM view is that savings from increasing quality always justify the cost. We need to consider the long-term strategic value of zero defect products, The advantages for automation when defects are eliminated, and The incremental savings to current and future product lines over many years. Part IV Cost of Quality Juran’s COQ Relationships Failure Costs Appraisal and Prevention Cost 0 % of Conformance 95% •Costs versus benefits — an efficient level of inefficiency (scientific management). •Long-Term strategic value exceeds the costs of prevention (TQM management). The Four Classifications of COQ Quality Conformance activities. Prevention costs are the monies spent to stop quality failures from happening. Appraisal costs are the monies spent to identify failures that have happened. Quality Nonconformance activities. Internal failure costs are monies spent due to failures before the products reach the customer. External failure costs are monies spent and value lost due to failures in the hands of the customers. Costs of Quality Examples Prevention cost examples: New equipment to improve quality and prevent problems. Training in new methods to improve quality and prevent problems. Rewards to motivate high quality. ISO certification. Technical support to suppliers. Preventive maintenance. More Costs of Quality Examples Appraisal cost examples: Inspection of materials. Process inspection within each activity. Final inspection of finished products. Test equipment. More Costs of Quality Examples Internal failure cost examples: Scrapping bad materials. Reworking subassemblies. Reworking finished products. Rejecting defective products. Retesting reworked components or finished products. More Costs of Quality Examples External failure cost examples: Warranty work. Product replacements. Recalls. Product liability insurance, legal fees, etc. Handling customer complaints. Lost sales and customers. Reporting the Costs of Quality Review, analyze and discuss Exhibit 11-3, p. 397, which provides an example of one method of preparing a Cost of Quality Report. Trend Reports $ 1 ,0 0 0 Cost ($000) $800 $600 E x t e rn a l fa ilu re s In t e rn a l fa ilu re s A p p ra is a l $400 P re ve n t io n $200 $0 1 2 3 T im e P e rio d s 4 5 Lost Sales and Customers The treatment of this issue varies from company to company. It is subjective (soft) data and does not comply with GAAP (hard data) concepts. Estimates of both current and future losses in value are required. Determination of these costs requires a very thorough understanding of the business and its customers. Measuring Value to External Consumers — Examples Critical success factors Quality Management accounting system measures Service Cost Number of warranty claims Average number of warranty claims per home Ratio of customer testimonials to homes sold Time to approval for sales contracts Time to approval for loan agreements Warranty work time to completion Sales price variance using competition’s prices Warranty cost as a percentage of profit per house Costs of quality reports Part V Process Value Analysis (PVA) & Activity-Based Management (ABM) Measuring Customer Value Identify value adding and nonvalue adding activities. Value adding activities (VA) are identified by the characteristics the customers (internal or external) value. In a value chain, each subsequent activity is the customer of the previous activity. Any change in a VA activity should only be made after consulting the affected customers. Nonvalue adding activities (NVA) should be eliminated (if possible) or minimized. Performance Measures Performance measures should be based upon value measures of quality, service, and cost. Exhibit 11-6, p. 401, follows to illustrate potential performance measures for external customers. Exhibit 11-7, p. 401, also follows to illustrate potential performance measures for internal customers. Measuring Value to External Consumers — Examples Critical success factors Quality Management accounting system measures Service Cost Number of warranty claims Average number of warranty claims per home Ratio of customer testimonials to homes sold Time to approval for sales contracts Time to approval for loan agreements Warranty work time to completion Sales price variance using competition’s prices Warranty cost as a percentage of profit per house Costs of quality reports Measuring Value to Internal Consumers — Packing measures for Shipping Critical success factors Quality Management accounting system measures Service Cost Amount of damage during shipment due to poor packaging materials Extra time required in shipping because of poorly packaged components Time waiting to load houses and packaged components Time waiting for packaging materials Time to approval for loan agreements % of boxes not adequately labeled Cost of rework or replacement for damage caused during shipment Extra cost from time trying to find building site (due to poor directions, maps, etc.) ABM vs. ‘Management by the Numbers’ Management by the numbers using management by exception examines the outcome of work done. Activities are only indirectly measure by cost data. Activities are the sources of cost consumption. Activities need to be managed — not costs. It is more efficient to manage activities to maximize value rather than managing costs. Well-managed activities result in higher quality products, better customer service, and lower costs. Management by the number is not an attempt to understand the root causes of, or elimination of, nonvalue adding activities. Continuous Improvement (Kaizen) Costing TQM makes incremental changes on a continuing basis — Continuous Improvement (CI). Kaizen (which means continuous improvement in Japanese) costing means we are continuously changing cost standards. Employee training and empowerment is crucial. The Relationship Between Target and Kaizen Standard Costs $130 Cost per unit $120 $110 $100 Target cost $ 90 $ 80 Introduction Growth Maturity Life cycle stages Decline Part VI Measuring the Impact of NVA Costs Illustrations The next few slides demonstrate the evaluation of and impact of Nonvalue Added activities. PVA for Framing Walls — Activity 3.2 Process 3: Manufacturing Steps in Activity 3.2 Classification 1. Requisition lumber (2 x 4 studs) from WIP Nonvalue-added 2. Process material requisition form (check for materials availability, schedule forklift and driver) Nonvalue-added 3. Forklift driver picks up lumber from stock yard Nonvalue-added 4. Forklift driver delivers lumber to Assembly Nonvalue-added 5. Stack according to when and where it is used Nonvalue-added 6. Set up jigs to hold walls in place Nonvalue-added 7. Lay down 12 2x4s for bottom of walls in the jigs Value-added 8. Measure and mark for location of wall studs Value-added 9. Get nails and brackets from inventory Nonvalue-added 10. Pick up each 8’ 2x4 wall stud and set on the mark Value-added 11. Nail the stud in place using 90o angle brackets Value-added Lead Time Efficiency (LTE) Ratio Process 3: Manufacturing Activity 3.2: Wall assembly (framing) LTE Value = Value-added time Value-added + Nonvalue-added time = 4 hours 4 + 12 hours = 25% Activity Cost Table Review and analyze Exhibit 11-12, p. 409. Notice the time spent on Nonvalue-added activities and the costs involved. In this case we cannot eliminate all of the nonvalue-added costs. However, the cost table does provide us relevant information and indicates that we may be able to increase efficiency and thereby reduce costs. Part VII Improving VA Activities — Identifying the Core Problems Fishbone Diagrams Basic Fishbone Diagram Model Causes Results See Exhibit 11-13, p. 411 for a completed fishbone diagram. Pareto Charts $1,000 $900 $800 $700 100% 80% $600 $500 60% $400 $300 $200 40% 20% $100 $0 0% Benchmarking Benchmarking is the practice of comparing our activities to similar activities from ‘best practices’ companies. The activities do not have to be identical as to their goals, just similar as to their activities. Benchmarking may be accomplished using data from internal activities in our own organization. TQM Problems and Prescriptions Reasons why TQM initiatives fail: Incongruent organizational culture Reward system does not support TQM The search for a quick fix Recommendations TQM becomes a formula rather than a philosophy Top management must be committed Top management cannot dictate that TQM will happen Employees must be empower to do it Reward employees for TQM activities Use easy to understand measures TQM must start with value chain process and activities Change from a department focus to an activity focus Develop employee excitement for TQM