1.1 Significance of testing materials

advertisement

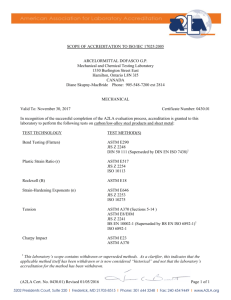

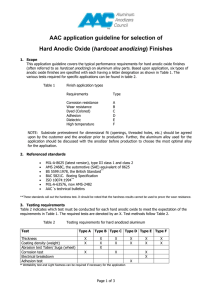

CHAPTER I Testing of Material Properties 1 1.1 Significance of testing materials The testing of materials may be performed with one of the three points below: (1) to supply routine information on the quality of a product- commercial or control testing, (2) to develop new or better information on known materials or to develop new materialsmaterials research, (3) to obtain accurate measures of fundamental properties of materials- scientific measurement. 2 Commercial testing Commercial testing is concerned with; checking the acceptability of materials with respect to the specifications, control of production. Generally, the type of the test has been specified, standard procedures are used, and the object is to determine whether the properties of a material fall within the required limits. 3 Materials research Materials research is done in order to; (1) obtain new understanding of known materials, (2) discover the properties of new materials, (3) develop meaningful standards of quality or test procedures. 4 Scientific testing Scientific testing is the accumulation of orderly and reliable informations on the fundamental and useful properties of materials. 5 What is the difference between experiments and tests? Experimentation means that the outcome is uncertain, that new insights are to be gained. Testing is a more defined procedure, with the limits and results are clear. 6 Materials testing may be carried out on 1. Full size structures, members, or parts, 2. Models of structures, members, or parts, 3. Specimens cut from finished parts, 4. Specimens of raw or processed materials, 7 Destructive testing vs Non-destructive testing Destructive testing is carried out until the specimen’s failure. These tests are generally much easier to carry out, yield more information and are easier to interpret than non-destructive testing Non-destructive testing is the type of testing that does not destroy the test object. It is vital when the material in question is still in service. 8 Field Tests vs Laboratory Tests Field tests usually lack the precision of similar tests conducted in the laboratory, However, some tests cannot be made in the laboratory and others cannot be made in the field. 9 Precision & Accuracy Precision: repeatability of a measurement Accuracy: its closeness to the true value Exp/ If an instrument consistently gives nearly identical but wrong readings- precise but inaccurate If readings vary considerably but do center about the true value- accurate but imprecise Test results should be both precise and accurate! 10 1.2 Standard Specifications & Standardizing Agencies Specification: A precise statement of a set of requirements, to be satisfied by a material, product, system or service. It is desirable that the requirements, together with their limits, should be expressed numerically in appropriate units. A standard specification for a material is the result of agreement between those concerned in a particular field and involves acceptance for use by participating agencies. 11 Standardizing Agencies & Relevant Standards Turkish Standards Institute (TSE)-Turkish Standards (TS) http://www.tse.org.tr/ American Society for Testing and Materials (ASTM)- ASTM Specifications http://www.astm.org International Standards Organization (ISO)ISO Standards http://www.iso.org European Commitee for Standardization (CEN)- European Norms (EN) http://www.cen.eu 12 1.3 Properties of Engineering Materials Principal materials used in construction are; metals, woods, portland cement concretes, bituminous mixtures, clay products, masonry materials, plastics. 13 Engineering Materials The principal function of these materials is to develop Strength, Rigidity, Durability, adequate to the service for which they are intended. 14 An important property- Strength The major work of the ordinary materials testing laboratory has to do with mechanical properties. – mechanical testing A first requirement of any engineering material is adequate strength The term testing machine refers to a machine for applying loads. 15 Properties of engineering materials-1 Class Property General Density or specific gravity, Porosity Moisture content Macrostucture Microstructure Chemical Oxide or compound composition Acidity or alkalinity Resistance to corrosion or weathering 16 Properties of engineering materials-2 Class Physicochemical Property Water-absorptive or water-repellent action Shrinkage and swell due to moisture changes Mechanical Strength: Tension, compression, shear and flexure Stiffness Elasticity, plasticity Ductility, brittleness Hardness, wear resistance 17 Properties of engineering materials-3 Class Thermal Electrical and magnetic Property Specific heat Expansion Conductivity Conductivity Magnetic permeability Galvanic action 18 Properties of engineering materials-4 Class Acoustical Optical Sound transmission Sound reflection Color Light transmission Light reflection 19 TASK Visit the Civil Engineering laboratory, notice where the general equipment is located. Learn the instruction of the operation of the compressive strength testing machine. 20 References “The Testing of Engineering Materials,” H.E. Davis, G.E. Troxell and G.F.W. Hauck, McGrawHill Book Company, 1964. “The Science and Technology of Civil Engineering Materials,’’ J. F. Young; S. Mindess; R.J. Gray and A. Bentur, Prentice Hall, 1998. “Civil Engineering Materials,” S. Somayaji, Prentice Hall, NJ, 1995. “Design and Control of Concrete Mixtures”, Portland Cement Association, USA, 1979. www.wikipedia.org 21