Literature Review

advertisement

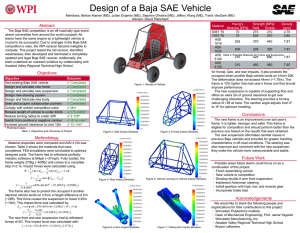

Saluki Engineering Company Team 31 SAE Baja Suspension Literature Review Team Leader: Brett Probst Team Members: Joe Antonaci Harjot Singh Philip Thompson Josh Walker Table of Contents Abstract Review of Literature Rules SIUC Baja General Dimension – JA Suspension Overview – JW & HS Front Suspension - JW Rear Suspension - HS Steering/Spindles – PT Conclusion Works Cited Abstract SAE Baja hosts annual collegiate competitions where teams design, build, and race a Baja. SIU’s Baja team competed in 2012 and will do so again in 2013. Saluki Engineering Company Team 31, Baja Suspension, has the task of developing the suspension for this year’s vehicle. This will consist of designing the front suspension, rear suspension, steering system, and spindles. The final aspect of the suspension is the shocks. Unfortunately, there will not be enough funding to purchase custom shocks that will fit the suspension design. Therefore, the team will need to create a design with a geometry and weight distribution that can incorporate last year’s shocks. The team must also design the suspension to conform to strict SAE Baja rules. SAE Baja Competition Rules The Baja competitions are hosted and strictly regulated by SAE Baja. At the beginning of all SAE Baja competitions, teams are required to submit to a technical inspection. During this technical inspection judges must determine that a team’s Baja is safe, was built with quality engineering practices, and conforms to all competition rules. If a team is found to not meet these requirements, the team is not allowed to compete. There are few limitations with regards to the suspension, but basic design requirements shown below are taken the 2013 SAE Baja Rules: Figure 1: SAE Mini Baja Technical Requirements Saluki Baja Background The Saluki Baja team submitted its first vehicle in the 2012 SAE Baja Midwest Competition. The analysis of the previous submission will serve as an important reference in the design of the 2013 submission. For the SIUC team, as well as many others, the suspension presented the largest room for improvement. Key issues with the suspension included low ride height, ball joint failure, insufficient suspension travel, a high center of gravity, and loose steering. The low ride height and travel constraints made it difficult to navigate the rough terrain of the course. Because the suspension often moved through its entire range of motion, various parts of the vehicle were subjected to large stresses, severely increasing the potential for component failure. One such example was the ball joints in the front suspension, where improper geometry resulted in multiple breakdowns. The high center of gravity meant that vehicle was prone to roll-overs. This was not only a safety concern but also created the potential for damage to the vehicle and disqualification from the race. Though the suspension was certainly a factor with regard to the center of gravity, the low ride height suggests that the source of the issue was largely related to mass distribution within the frame. The last major issue was the durability of the steering where insufficient support caused the steering shaft to bend. In addition, the tie rod ends were subjected to high stress, which resulted in failure. The extreme stress was caused by the geometry of the spindle. The vehicle utilized an OEM spindle which was not appropriate for that application. The spindle was too narrow, causing alignment issues and a tendency to shear. Devising solutions to these design issues represent the main challenges of the 2013 suspension design team. General Dimensions As noted above, the SIUC 2012 Mini Baja submission will serve as a reference for the design and construction of the 2013 Baja. During the design phase, the SIUC team will also consider data collected from other teams when available. Design reports are available from India-Purdue University at Fort Wayne [1], the University of Tennessee at Chattanooga [2], the University of Wisconsin at Platteville [3], and Brigham Young University – Idaho [4]. Some of the general data from these reports has been compiled below. University SIU-C IPU-FW IPU-FW Year of Submission 2012 2008 2007 Competition Midwest Midwest Midwest Empty Weight 597 472 NA Weight w/ Driver 700 NA NA Overall Length 93 88 92 Maximum Width 52 53 62 Wheel Track NA NA NA Static Ride Height - Front 10.5 12 12 Travel - Front 8 7 7 Static Ride Height - Rear 10.5 12 12 Travel - Rear 7 3.5 7 Weight Distribution 36:64 36:64 NA Table 1:General Dimensions of Various Baja Submissions UT-C 2006 Midwest 430 600 92.5 54 48.5 10 10 10 8 40:60 UW-P 2009 Midwest NA 500 NA NA 56 12 NA 12 NA NA BYU-I 2005 West NA NA NA NA NA 11.5 10 14 12 NA BYU-I 2004 West NA NA NA NA NA 8 5 10 8 NA AVG NA NA 500 600 91.38 55.25 52.25 10.86 7.83 11.50 7.58 37:63 Suspension Overview The purpose of the suspension for conventional land vehicles is to dampen the effects of the terrain it encounters and to assist in braking. A suspension system generally consists of dampener or shock absorber, springs, and multiple linkages. The dampener ensures that the forces generated between the ground and wheels are dissipated before reaching the frame of the vehicle. The purpose of the spring is to maintain the contact between the tires and the ground. Most Baja submissions employ an independent front and rear suspension. This design allows each tire in the suspension to move separately from another other. An independent suspension creates a more comfortable ride and allows for better handling on uneven terrain. Steering responsiveness can be greatly affected by the spring rate of the coil/shock setup. Spring rate is defined as the amount of force it takes to compress a spring 1 inch [5]. The spring rate is usually specified by the manufacture and can be used to determine the force exerted by the spring according to the following equation: 𝐹 = −𝑘∆𝑥 (𝐹𝑜𝑟𝑐𝑒 𝑜𝑓 𝐴 𝑆𝑝𝑟𝑖𝑛𝑔) Equation 1 Where k is the spring rate, Δx is the length of compression (or extension) of the spring, and F is the resulting force. This force is what "pushes" the tire toward the ground in order to maintain contact. The weight (force exerted) by the shock setup greatly contributes to the handling of the vehicle. The weight of the body and all the parts mounted on it are considered sprung weight. The tires, wheels, and suspension parts, which will move up and down with the wheels, are underneath the springs and will not be insulated from the road conditions. These moving suspension parts are considered un-sprung weight. The SAE Baja Competition requires a design concept for a durable vehicle that could be mass produced as a production All-Terrain Vehicle. Due to the rugged nature of the courses, a high sprung-to-un-sprung weight ratio is desirable to maintain contact with the ground. This relationship can be calculated for the vehicle by dividing the total sprung weight by the total un-sprung weight of all four wheels. The figure to the right gives an example of a weight ratio breakdown for the individual suspension components. The wheel, tire, stub axle, and upright all move together as a rigid unit, and thus are all 100% unsprung weight. The axle shaft and the lower suspension arm are both 50% un-sprung, an average between the two ends. The shock is 36% un-sprung because the lower end moves 72% of the un-sprung motion. The 36% is taken from the average of the two ends of the shock. The coil spring mounted on the shock is also 36% un-sprung weight. Figure 2: Weight Ratio Illustration There are many types of materials that can be used to form the members of the suspension components. The most widely used materials different varieties of alloy steel. The steel is generally stamped, rolled, or square tubing. Steel has relatively high yield strength, allowing it to withstand repeated impact without deforming. Steel also has a rather large area within the plastic region once elongation surpasses the yielding point. This allows a significant amount of deformation to occur before fracture, meaning damage can be identified before complete member failure occurs. Composite materials are also available, but these material are generally cost prohibitive. The Stress versus Strain curve for typical alloy steels is provided below. Figure 3: True Stress Versus True Strain for Alloyed Steels Front Suspension The 2011-2012 Baja front suspension incorporated an independent front suspension. It consisted of a double A-Arm construction that connected to the frame with Heim joints. The Heim joints were an excellent choice since they allow for some error in frame-to-arm alignment. They also tend to outlast the traditional rubber and urethane bushings. The Heim joints were threaded into the A-Arms which allowed for caster and camber adjustments. The spindles connected to the A-Arms through ball joints. King UTV coil-over shocks were used and mounted to the lower control arms. This style of design has been used by many other teams and in production vehicles for many years. However, problems did arise from improper geometry of the system. This included multiple ball joint failures, insufficient wheel travel, overall vehicle weight, and rollovers. Pictures of a typical A-Arm setup, the previous front suspension, caster/camber adjustment, and Heim joints are below. \ Figure 4: A-Arm Suspension Camber Adjustment Heim Joint Location Figure 5: Camber/Caster Adjustment [7] Figure 6: Heim Joints Some variations of the front A-Arm suspension are pictured below. The pictures were taken at the 2012 SAE Baja Competition in Alabama. Notice that all of these have the same concept, but very in dimension and orientation. The coil/shock location, A-Arm length, ride height, and tierods are some of the main differences. Figure 7: Various A-Arm Suspension Designs There are other ways to configure the front suspension. One of which was designed by the 2011 Senior Design students at The University of Texas at El Paso (UTEP) as seen in the figure below. It eliminated the use of the double A-Arm suspension and instead used a single, larger, lower control arm and a solid adjustable shaft for the upper control arm. The lower control arm was reinforced to withstand the increased loads it would be subjected to. The advantage is that there is less material present in the upper control arm and a much cleaner design. However, it seems that the single upper control arm contact point would allow unwanted movement at the spindle. Also, the material removed from the upper Figure 8: UTEP Front Suspension control arm has to be compensated for with the increased lower control arm size. [6] Rear Suspension A variety of mounting systems for rear suspension have been used in competition with the two most prevalent being double A-arms and trailing arms or a combination of the two. Unlike the front suspension, the rear suspension will have to integrate a drive-train in the design as well. Trailing arms can also be used as a rear suspension links. The main characteristic is the use of a single arm to connect the frame to the knuckle making this kind of suspension the simplest to setup as well as a lighter weight benefit. Trailing arms also have little room for failure due to the fact it rotates on the same axis of rotation as the tires will. An A arm design in the rear suspension is composed of two link arms mounted one on top of the other. The arms can be either equal in length or have different lengths. This system does increase the weight of the vehicle comparative to having a single trailing arm as well as being more prone to failure under heavy stresses during the race. Figure 9: Various A-Arm Designs Figure 10: Standard Trailing Arm Steering The steering apparatus is considered an independent system, but as it shares a dynamic relationship with the suspension, a general overview is given. The spindle is the central component of the front suspension. The spindle is where the steering mechanism connects to the suspension and it is also the where the suspension arm(s) are mounted and the component about which the wheel rotates. The spindles must withstand the loads transferred from each of the components in varying directions and magnitudes. Thus it is important to conduct a rigorous stress analysis when designing the spindles. For this reason, the material properties of the spindles must be carefully considered as well. The table below shows a compares key properties and cost estimate for prospective materials. Material Density 6061 Aluminum Ti 6-4 (Titanium) 304 Stainless Steel 0.0975 lb/in3 0.16 lb/in3 0.289 lb/in3 Max Yield Strength (psi) 8,000 141,000 73,200 Cost/Pound $2.00 to $5.00 $25.00 to $50.00 $2.00 to $4.00 Table 2: Material Property Comparison A common type of steering system used in the Baja Competition is a rack and pinion. A pinion is a circular gear that, when rotated by the steering shaft, causes linear movement of the rack. A basic rack and pinion mechanism is shown below. This linear motion is translated to the individual wheels by the long thin members called tie rods. Tie rods must be able to withstand both tensile and compressive stress with minimal deformation for responsive handling. The tie rods connect to the feature of the spindles called the steering arms. The steering arm acts as a lever to rotate the spindles about their connection to the suspension arm, thus turning the wheels. Figure 11: Rack and Pinion The previous Baja design utilized a rack and pinion mechanism that was walled off from the acceleration and brake pedals. The location of the steering components increased the size of the front end, adding extra frame weight, and increasing the turning radius of the Baja. When selecting the size of the rack and pinion, several factors will be must be considered. The first is the size of the rack. To utilize the full range of motion of the rack, the frame must be nearly twice as wide as the length of the rack. A larger rack will offer a wider and more precise range of motion in the spindles but will increase the size of the front end and decrease the turning radius. As the size of the rack decreases, so will the size of the frame, but the result will be a decrease in handling. Another factor is the size of the pinion. For a given torque in the steering shaft, the amount of force delivered to the spindles will be determined by the ratio of the rack to the radius of the pinion. Decreasing pinion size will increase the precision of the steering but will apply less force. Also the relative size of the steering wheel will determine the torque that can be applied to rack. Finally the distance from the tie rod connection to the pivot point of the spindle will determine the torque applied to turn the wheels. Summary After conducting research and assessing different designs, the Baja Suspension Team has a better understanding of their goals. The ultimate goal of the project is to develop a suspension system that will dramatically increase performance. However, the design must remain cost effective, easy to fabricate, and adhere to SAE Baja rules. Given the budget, manufacturing capabilities, and other considerations, the following components show potential for the suspension design: double A-arm front suspension, rear trailing arm, and rack and pinion steering. Works Cited [1] Colone, Mike, et al. SAE Mini-Baja® 2008 – Suspension and Frame Design: Senior Design Report. Rep. N.p.: n.p., n.d. Web. 26 Sept. 2012. <new.ipfw.edu/dotAsset/239508.pdf>. [2] Gilbert, Mark, and Jeremy Goodman. 2006 Midwest Mini Baja Team. Rep. SAE International, 2006. Web. 27 Sept. 2012. <http://www.utc.edu/Departments/engrcs/UTCMWMB.pdf>. [3] Behrens, Brendan, and Kyle Droessler. Mini Baja Team: 2009 Design Report. Rep. SAE International, 2009. Web. 27 Sept. 2012. <http://www.uwplatt.edu/org/sae/Baja/20082009/University%20of%20Wisconsin%20Platteville_Baja%20Wisconsin.pdf>. [4] Johnson, Ben. SAE Mini-Baja West Design Report. Rep. SAE International, 2005. Web. 26 Sept. 2012. <http://www2.byui.edu/Societies/SAE/2006%20Buggy.pdf>. [5] Huber, A., "All About Spring Rates", in Chassis and Suspension Handbook, First Edition, HP Books, Division of Penguin Group (USA) Inc., New York, New York, pg. 1. [6] "MiniBaja Vehicle Suspension Design". 2011. [Online]. Available: me.utep.edu/mrkhan/Documents/FrontSuspentionDesignMiniBaja.pdf. [Accessed: September 25, 2012] [7] Bolles, B., "Caster and Camber Settings" , Jan. 2008, [Online] Available at http://www.circletrack.com/chassistech/ctrp_0801_caster_camber_settings/photo_09.html, [Accessed Sept. 29, 2012]. [8] Edmondson, Chuck, “Fast Car Physics,” Baltimore, Maryland: The Johns Hopkins University Press, 2011. [9] Smith, Carroll, “Engineer to Win,” Osceola, Wisconsin: MBI Publishing Company, 1984.