Closure

advertisement

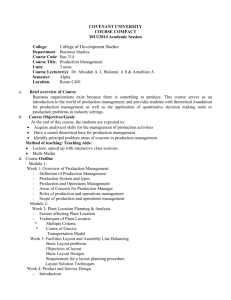

Closure Course Outline 1. Introduction a. Course Objectives, Context, and Outline b. Operations Management as a component of Corporate Strategy 2. Inventory Management for Pure Inventory Systems a. The EOQ formula and its variants b. Introduction to inventory control with stochastic demand: service level and safety stock 3. Production Planning and Control a. Production flows for discrete-part manufacturing and their documentation b. “Make-or-Buy” decisions and capacity planning c. Types of layout c. Aggregate Planning d. MRP Explosion for multi-stage production systems e. Lot Sizing f. Shop Floor Scheduling g. Pull Systems and the Just-In-Time Philosophy Course Outline 4. Layout Design a. Systematic Layout Planning a. Cellular Manufacturing: Cell Formation b. (Assembly) Line Balancing i. Deterministic Operational Context ii. Stochastic Operational Context c. Layout Problems in the Warehousing Context i. Overview of the Warehousing Operations, Organization and Product Flow ii. Storage Layouts iii. Design of the Fast-Pick Area iv. Cross-docking • For Systematic Layout Planning: Chpt 10 from your textbook and today’s lecture • For Warehousing: Prof. Bartholdi’s electronic textbook on Warehousing Science Design of Process-based layouts Arrange spatially the facility departments in a way that • facilitates the flow of parts through the facility by minimizing the material handling / traveling effort; • observes additional practical constraints arising from, e.g., • processing/operational requirements • safety/health considerations • aesthetics • building features • etc. Prevailing Methodology: Systematic Layout Planning (SLP) 1. Material Flows 2. Activity Relationships 3. REL Chart 4. REL Diagram 5. Space Requirements 6. Space REL Diagram 7. Space Availability 8. Layout Alternatives Departments Activities Example on SLP Developed in class – c.f. your class notes!