Chapter 18: Electrical Properties

advertisement

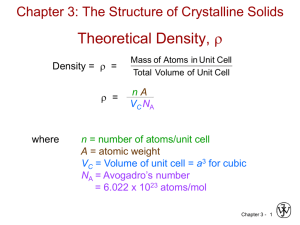

EED2013 Engineering Materials Non-Mechanical Properties of Materials 1 Overview • • • • Electrical Properties Magnetic Properties Thermal Properties Durability 2 Electrical Properties ISSUES TO ADDRESS... • How are electrical conductance and resistance characterized? • What are the physical phenomena that distinguish conductors, semiconductors, and insulators? • For metals, how is conductivity affected by imperfections, temperature, and deformation? • For semiconductors, how is conductivity affected by impurities (doping) and temperature? 3 View of an Integrated Circuit • Scanning electron micrographs of an IC: Al Si (doped) (d) (d) (a) 45 mm 0.5 mm • A dot map showing location of Si (a semiconductor): -- Si shows up as light regions. (b) • A dot map showing location of Al (a conductor): -- Al shows up as light regions. Fig. (d) from Fig. 12.27(a), Callister & Rethwisch 3e. (Fig. 12.27 is courtesy Nick Gonzales, National Semiconductor Corp., West Jordan, UT.) (c) Figs. (a), (b), (c) from Fig. 18.27, Callister & Rethwisch 8e. 4 Electrical Conduction • Ohm's Law: V=IR voltage drop (volts = J/C) resistance (Ohms) current (amps = C/s) C = Coulomb • Resistivity, : -- a material property that is independent of sample size and geometry RA l • Conductivity, surface area of current flow current flow path length 1 5 Electrical Properties • Which will have the greater resistance? 2 R1 D 2D 2 D 2 2 8 D2 R1 R2 2 2 8 2D D 2 • Analogous to flow of water in a pipe • Resistance depends on sample geometry and size. 6 Definitions Further definitions J= <= another way to state Ohm’s law J current density current I surface area A like a flux electric field potential = V/ J = (V/ ) Electron flux conductivity voltage gradient 7 Conductivity: Comparison • Room temperature values (Ohm-m)-1 = ( - m)-1 METALS CERAMICS conductors -10 Silver 6.8 x 10 7 Soda-lime glass 10 -10-11 Copper 6.0 x 10 7 Concrete 10 -9 Iron 1.0 x 10 7 Aluminum oxide <10-13 SEMICONDUCTORS POLYMERS Polystyrene Silicon 4 x 10 -4 Polyethylene Germanium 2 x 10 0 GaAs 10 -6 semiconductors -14 <10 10 -15-10-17 insulators Selected values from Tables 18.1, 18.3, and 18.4, Callister & Rethwisch 8e. 8 Example: Conductivity Problem What is the minimum diameter (D) of the wire so that V < 1.5 V? 100 m I = 2.5 A Cu wire - V 100 m D 2 4 Solve to get + R < 1.5 V V A I 2.5 A 6.07 x 107 (Ohm-m)-1 D > 1.87 mm 9 Relative Permittivity, εr • Property governs the electro-static charge stored on an electric capacitor. • The main equation that this is found is: C = εoεrA/d where C = capacitance in Farads A = area of the capacitor plate d = distance between the capacitor plates εo = absolute permittivity (8.85 x 10-12) 10 Relative Permittivity, εr • Here is a table of some example values of εr: 11 Band Structure Representation Adapted from Fig. 18.3, Callister & Rethwisch 8e. 12 Conduction & Electron Transport • Metals (Conductors): partly filled band filled band filled states - partially filled band - empty band that overlaps filled band filled states -- for metals empty energy states are adjacent to filled states. -- thermal energy Partially filled band Overlapping bands excites electrons Energy Energy into empty higher empty energy states. band empty -- two types of band GAP band structures for metals 13 filled band filled band Energy Band Structures: Insulators & Semiconductors • Insulators: • Semiconductors: -- wide band gap (> 2 eV) -- narrow band gap (< 2 eV) -- few electrons excited -- more electrons excited across band gap across band gap empty Energy Energy empty conduction conduction band band filled valence band filled band ? GAP filled states filled states GAP filled valence band filled band 14 Metals: Influence of Temperature and Impurities on Resistivity • Presence of imperfections increases resistivity (10 -8 Ohm-m) Resistivity, -- grain boundaries -- dislocations -- impurity atoms -- vacancies 6 These act to scatter electrons so that they take a less direct path. • Resistivity 5 increases with: 4 3 d 2 i 1 0 -- temperature -- wt% impurity -- %CW t -200 -100 0 T (ºC) Adapted from Fig. 18.8, Callister & Rethwisch 8e. (Fig. 18.8 adapted from J.O. Linde, Ann. Physik 5, p. 219 (1932); and C.A. Wert and R.M. Thomson, Physics of Solids, 2nd ed., McGraw-Hill Book Company, New York, 1970.) = thermal + impurity + deformation 15 Estimating Conductivity • Question: 180 160 140 125 120 100 21 wt% Ni 80 60 0 10 20 30 40 50 Resistivity, (10 -8 Ohm-m) Yield strength (MPa) -- Estimate the electrical conductivity of a Cu-Ni alloy that has a yield strength of 125 MPa. wt% Ni, (Concentration C) Adapted from Fig. 7.16(b), Callister & Rethwisch 8e. From step 1: CNi = 21 wt% Ni Adapted from Fig. 18.9, Callister & Rethwisch 8e. 50 40 30 20 10 0 0 10 20 30 40 50 wt% Ni, (Concentration C) 8 30 x 10 Ohm m 1 3.3 x 106(Ohm m)1 16 Charge Carriers in Insulators and Semiconductors Adapted from Fig. 18.6(b), Callister & Rethwisch 8e. Two types of electronic charge carriers: Free Electron – negative charge – in conduction band Hole – positive charge – vacant electron state in the valence band Move at different speeds - drift velocities 17 Intrinsic Semiconductors • Pure material semiconductors: e.g., silicon & germanium – Group IVA materials • Compound semiconductors – III-V compounds • Ex: GaAs & InSb – II-VI compounds • Ex: CdS & ZnTe – The wider the electronegativity difference between the elements the wider the energy gap. 18 Intrinsic Semiconduction in Terms of Electron and Hole Migration • Concept of electrons and holes: valence electron electron hole pair creation Si atom + - no applied electric field electron hole pair migration applied electric field • Electrical Conductivity given by: + applied electric field Adapted from Fig. 18.11, Callister & Rethwisch 8e. # holes/m3 n e me p e m h # electrons/m3 hole mobility electron mobility 19 Number of Charge Carriers Intrinsic Conductivity n e me p e m h • for intrinsic semiconductor n = p = ni = ni|e|(me + mh) • Ex: GaAs 106 ( m) 1 ni e me mh (1.6x1019 C)(0.85 0.45 m2 /V s) For GaAs For Si ni = 4.8 x 1024 m-3 ni = 1.3 x 1016 m-3 20 Intrinsic Semiconductors: Conductivity vs T • Data for Pure Silicon: -- increases with T -- opposite to metals ni e me mh E gap / kT ni e material Si Ge GaP CdS band gap (eV) 1.11 0.67 2.25 2.40 Selected values from Table 18.3, Callister & Rethwisch 8e. Adapted from Fig. 18.16, Callister & Rethwisch 8e. 21 Intrinsic vs Extrinsic Conduction • Intrinsic: -- case for pure Si -- # electrons = # holes (n = p) • Extrinsic: -- electrical behavior is determined by presence of impurities that introduce excess electrons or holes -- n ≠ p • n-type Extrinsic: (n >> p) • p-type Extrinsic: (p >> n) Phosphorus atom 4+ 4+ 4+ 4+ n e me 4+ 5+ 4+ 4+ 4+ 4+ 4+ 4+ Adapted from Figs. 18.12(a) & 18.14(a), Callister & Rethwisch 8e. no applied electric field Boron atom hole conduction electron 4+ 4+ 4+ 4+ valence electron 4+ 4+ 4+ 4+ Si atom 4+ 3+ 4+ 4+ no applied electric field p e mh 22 Extrinsic Semiconductors: Conductivity vs. Temperature • Data for Doped Silicon: -- increases doping -- reason: imperfection sites -- extrinsic doping level: 1021/m3 of a n-type donor impurity (such as P). -- for T < 100 K: "freeze-out“, thermal energy insufficient to excite electrons. -- for 150 K < T < 450 K: "extrinsic" -- for T >> 450 K: "intrinsic" 1 extrinsic 2 intrinsic 3 freeze-out extrinsic conduction... concentration (1021/m3) • Comparison: intrinsic vs undoped Conduction electron lower the activation energy to produce mobile electrons. doped 0 0 200 400 600 T (K) Adapted from Fig. 18.17, Callister & Rethwisch 8e. (Fig. 18.17 from S.M. Sze, Semiconductor Devices, Physics, and Technology, Bell Telephone Laboratories, Inc., 1985.) 23 p-n Rectifying Junction • Allows flow of electrons in one direction only (e.g., useful to convert alternating current to direct current). • Processing: diffuse P into one side of a B-doped crystal. + p-type + + + + -- No applied potential: no net current flow. -- Forward bias: carriers flow through p-type and n-type regions; holes and electrons recombine at p-n junction; current flows. -- Reverse bias: carriers flow away from p-n junction; junction region depleted of carriers; little current flow. n-type - - - Adapted from Fig. 18.21 Callister & Rethwisch 8e. - p-type + - + - n-type + ++- - + - + p-type + + + + n-type - - - - + 24 Properties of Rectifying Junction Fig. 18.22, Callister & Rethwisch 8e. Fig. 18.23, Callister & Rethwisch 8e. 25 Summary • Electrical conductivity and resistivity are: -- material parameters -- geometry independent • Conductors, semiconductors, and insulators... -- differ in range of conductivity values -- differ in availability of electron excitation states • For metals, resistivity is increased by -- increasing temperature -- addition of imperfections -- plastic deformation • For pure semiconductors, conductivity is increased by -- increasing temperature -- doping [e.g., adding B to Si (p-type) or P to Si (n-type)] • Other electrical characteristics -- ferroelectricity -- piezoelectricity 26 Magnetic Properties ISSUES TO ADDRESS... • What are the important magnetic properties? • How does magnetic memory storage work? 27 Generation of a Magnetic Field -Vacuum • Created by current through a coil: B0 N = total number of turns = length of each turn (m) I = current (ampere) H = applied magnetic field (ampere-turns/m) B0 = magnetic flux density in a vacuum (tesla) H I • Computation of the applied magnetic field, H: H NI • Computation of the magnetic flux density in a vacuum, B0: B0 = m0H permeability of a vacuum (1.257 x 10-6 Henry/m) 28 Generation of a Magnetic Field -within a Solid Material • A magnetic field is induced in the material B applied magnetic field H current I B = Magnetic Induction (tesla) inside the material B = mH permeability of a solid m • Relative permeability (dimensionless) mr m0 29 Relative Permeability, μr • Property that governs the magnetic strength of a material. • The main equation that this property occurs is B/H = μoμr where B = flux density in Tesla H = magnetising force μo = absolute permeability (12.566 x 10-7) 30 B (tesla) Types of Magnetism (3) ferromagnetic e.g. Fe3O4, NiFe2O4 (4) ferrimagnetic e.g. ferrite(), Co, Ni, Gd ( cm as large as 106 !) (2) paramagnetic ( cm ~ 10-4) e.g., Al, Cr, Mo, Na, Ti, Zr vacuum (cm = 0) (1) diamagnetic (cm ~ -10-5) e.g., Al2O3, Cu, Au, Si, Ag, Zn H (ampere-turns/m) Plot adapted from Fig. 20.6, Callister & Rethwisch 8e. Values and materials from Table 20.2 and discussion in Section 20.4, Callister & Rethwisch 8e. 31 Magnetic Responses for 4 Types none opposing Adapted from Fig. 20.5(a), Callister & Rethwisch 8e. (2) paramagnetic random aligned Adapted from Fig. 20.5(b), Callister & Rethwisch 8e. (3) ferromagnetic (4) ferrimagnetic aligned Applied Magnetic Field (H) aligned No Applied Magnetic Field (H = 0) Adapted from Fig. 20.7, Callister & Rethwisch 8e. (1) diamagnetic 32 Domains in Ferromagnetic & Ferrimagnetic Materials • As the applied field (H) increases the magnetic domains change shape and size by movement of domain boundaries. B sat H Magnetic induction (B) H H H H 0 • “Domains” with aligned magnetic moment grow at expense of poorly aligned ones! Adapted from Fig. 20.13, Callister & Rethwisch 8e. (Fig. 20.13 adapted from O.H. Wyatt and D. Dew-Hughes, Metals, Ceramics, and Polymers, Cambridge University Press, 1974.) Applied Magnetic Field (H) H=0 33 Hysteresis and Permanent Magnetization • The magnetic hysteresis phenomenon B Stage 3. Remove H, alignment remains! => permanent magnet! Stage 2. Apply H, align domains H Stage 4. Coercivity, HC Negative H needed to demagnitize! Stage 5. Apply -H, align domains Adapted from Fig. 20.14, Callister & Rethwisch 8e. Stage 1. Initial (unmagnetized state) Stage 6. Close the hysteresis loop 34 Hard and Soft Magnetic Materials B -- large coercivities -- used for permanent magnets -- add particles/voids to inhibit domain wall motion -- example: tungsten steel -Hc = 5900 amp-turn/m) Soft Hard magnetic materials: H Soft magnetic materials: -- small coercivities -- used for electric motors -- example: commercial iron 99.95 Fe Adapted from Fig. 20.19, Callister & Rethwisch 8e. (Fig. 20.19 from K.M. Ralls, T.H. Courtney, and J. Wulff, Introduction to Materials Science and Engineering, John Wiley and Sons, Inc., 1976.) 35 Magnetic Storage • Digitized data in the form of electrical signals are transferred to and recorded digitally on a magnetic medium (tape or disk) • This transference is accomplished by a recording system that consists of a read/write head -- “write” or record data by applying a magnetic field that aligns domains in small regions of the recording medium -- “read” or retrieve data from medium by sensing changes in magnetization Fig. 20.23, Callister & Rethwisch 8e. 36 Magnetic Storage Media Types -- CoCr alloy grains (darker regions) separated by oxide grain boundary segregant layer (lighter regions) -- Magnetization direction of each grain is perpendicular to plane of disk 80 nm • Hard disk drives (granular/perpendicular media): Fig. 20.25, Callister & Rethwisch 8e. (Fig. 20.25 from Seagate Recording Media) • Recording tape (particulate media): ~ 500 nm ~ 500 nm Fig. 20.24, Callister & Rethwisch 8e. (Fig. 20.24 courtesy Fuji Film Inc., Recording Media Division) -- Acicular (needle-shaped) ferromagnetic metal alloy particles -- Tabular (plate-shaped) ferrimagnetic barium-ferrite particles 37 Summary • A magnetic field is produced when a current flows through a wire coil. • Magnetic induction (B): -- an internal magnetic field is induced in a material that is situated within an external magnetic field (H). -- magnetic moments result from electron interactions with the applied magnetic field • Types of material responses to magnetic fields are: -- ferrimagnetic and ferromagnetic (large magnetic susceptibilities) -- paramagnetic (small and positive magnetic susceptibilities) -- diamagnetic (small and negative magnetic susceptibilities) • Types of ferrimagnetic and ferromagnetic materials: -- Hard: large coercivities -- Soft: small coercivities • Magnetic storage media: -- particulate barium-ferrite in polymeric film (tape) -- thin film Co-Cr alloy (hard drive) 38 Thermal Properties ISSUES TO ADDRESS... • How do materials respond to the application of heat? • How do we define and measure... -- heat capacity? -- thermal expansion? -- thermal conductivity? -- thermal shock resistance? • How do the thermal properties of ceramics, metals, and polymers differ? 39 Heat Capacity The ability of a material to absorb heat • Quantitatively: The energy required to produce a unit rise in temperature for one mole of a material. heat capacity (J/mol-K) dQ C dT energy input (J/mol) temperature change (K) • Two ways to measure heat capacity: Cp : Heat capacity at constant pressure. Cv : Heat capacity at constant volume. Cp usually > Cv J Btu • Heat capacity has units of mol K lb mol F 40 Dependence of Heat Capacity on Temperature • Heat capacity... -- increases with temperature -- for solids it reaches a limiting value of 3R R = gas constant 3R = 8.31 J/mol-K 0 Cv = constant 0 qD • From atomic perspective: T (K) Adapted from Fig. 19.2, Callister & Rethwisch 8e. Debye temperature (usually less than T room ) -- Energy is stored as atomic vibrations. -- As temperature increases, the average energy of atomic vibrations increases. 41 Atomic Vibrations Atomic vibrations are in the form of lattice waves or phonons Adapted from Fig. 19.1, Callister & Rethwisch 8e. 42 Specific Heat: Comparison increasing cp Material • Polymers Polypropylene Polyethylene Polystyrene Teflon cp (J/kg-K) at room T 1925 1850 1170 1050 • Ceramics Magnesia (MgO) Alumina (Al2O3) Glass 940 775 840 • Metals Aluminum Steel Tungsten Gold 900 486 138 128 cp (specific heat): (J/kg-K) Cp (heat capacity): (J/mol-K) • Why is cp significantly larger for polymers? Selected values from Table 19.1, Callister & Rethwisch 8e. 43 Thermal Expansion Materials change size when temperature is changed Tinitial initial Tfinal final l f inal l l initial Tfinal > Tinitial l (Tf inal Tinitial ) initial linear coefficient of thermal expansion (1/K or 1/ºC) 44 Atomic Perspective: Thermal Expansion Asymmetric curve: -- increase temperature, -- increase in interatomic separation -- thermal expansion Symmetric curve: -- increase temperature, -- no increase in interatomic separation -- no thermal expansion Adapted from Fig. 19.3, Callister & Rethwisch 8e. 45 Coefficient of Thermal Expansion: Comparison Material increasing • Polymers Polypropylene Polyethylene Polystyrene Teflon • Metals Aluminum Steel Tungsten Gold • Ceramics Magnesia (MgO) Alumina (Al2O3) Soda-lime glass Silica (cryst. SiO2) (10-6/C) at room T 145-180 106-198 90-150 126-216 23.6 12 4.5 14.2 13.5 7.6 9 0.4 Polymers have larger values because of weak secondary bonds • Q: Why does generally decrease with increasing bond energy? Selected values from Table 19.1, Callister & Rethwisch 8e. 46 Thermal Expansion: Example Ex: A copper wire 15 m long is cooled from 40 to -9ºC. How much change in length will it experience? • Answer: For Cu 16.5 x 106 ( C)1 rearranging Equation 19.3b 0 T [ 16.5 x 10 6 (1/ C)](15 m)[ 40C ( 9C)] 0.012 m 12 mm 47 Thermal Conductivity The ability of a material to transport heat. Fourier’s Law heat flux (J/m2-s) dT q k dx temperature gradient thermal conductivity (J/m-K-s) T2 T1 x1 heat flux T2 > T1 x2 • Atomic perspective: Atomic vibrations and free electrons in hotter regions transport energy to cooler regions. 48 increasing k Thermal Conductivity: Comparison Material k (W/m-K) • Metals Aluminum 247 Steel 52 Tungsten 178 Gold 315 • Ceramics Magnesia (MgO) 38 Alumina (Al2O3) 39 Soda-lime glass 1.7 Silica (cryst. SiO2) 1.4 • Polymers Polypropylene 0.12 Polyethylene 0.46-0.50 Polystyrene 0.13 Teflon 0.25 Energy Transfer Mechanism atomic vibrations and motion of free electrons atomic vibrations vibration/rotation of chain molecules Selected values from Table 19.1, Callister & Rethwisch 8e. 49 Thermal Stresses • Occur due to: -- restrained thermal expansion/contraction -- temperature gradients that lead to differential dimensional changes Thermal stress E (T0 Tf ) E T 50 Example Problem -- A brass rod is stress-free at room temperature (20ºC). -- It is heated up, but prevented from lengthening. -- At what temperature does the stress reach -172 MPa? Solution: T0 Original conditions 0 Step 1: Assume unconstrained thermal expansion 0 Tf thermal (Tf T0 ) room Step 2: Compress specimen back to original length 0 compress thermal room 51 Example Problem (cont.) 0 The thermal stress can be directly calculated as E(compress) Noting that compress = -thermal and substituting gives E(thermal ) E (Tf T0 ) E (T0 Tf ) Rearranging and solving for Tf gives 20ºC Tf T0 Answer: 106ºC 100 GPa E -172 MPa (since in compression) 20 x 10-6/ºC 52 Thermal Shock Resistance • Occurs due to: nonuniform heating/cooling • Ex: Assume top thin layer is rapidly cooled from T1 to T2 rapid quench tries to contract during cooling T2 resists contraction T1 Tension develops at surface E (T1 T2 ) Critical temperature difference for fracture (set = f) Temperature difference that can be produced by cooling: (T1 T2 ) quench rate k (T1 T2 ) f racture f E set equal • (quench rate) f or f racture Thermal Shock Resistance ( TSR) • Large TSR when f k is large E f k E 53 Thermal Protection System • Application: Re-entry T Distribution Space Shuttle Orbiter Chapter-opening photograph, Chapter 23, Callister 5e (courtesy of the National Aeronautics and Space Administration.) • Silica tiles (400-1260ºC): -- large scale application reinf C-C silica tiles (1650ºC) (400-1260ºC) nylon felt, silicon rubber coating (400ºC) Fig. 19.2W, Callister 6e. (Fig. 19.2W adapted from L.J. Korb, C.A. Morant, R.M. Calland, and C.S. Thatcher, "The Shuttle Orbiter Thermal Protection System", Ceramic Bulletin, No. 11, Nov. 1981, p. 1189.) -- microstructure: ~90% porosity! Si fibers bonded to one another during heat treatment. 100 mm Fig. 19.3W, Callister 5e. (Fig. 19.3W courtesy the National Aeronautics and Space Administration.) Fig. 19.4W, Callister 5e. (Fig. 219.4W courtesy Lockheed Aerospace Ceramics Systems, Sunnyvale, CA.) 54 Summary The thermal properties of materials include: • Heat capacity: -- energy required to increase a mole of material by a unit T -- energy is stored as atomic vibrations • Coefficient of thermal expansion: -- the size of a material changes with a change in temperature -- polymers have the largest values • Thermal conductivity: -- the ability of a material to transport heat -- metals have the largest values • Thermal shock resistance: -- the ability of a material to be rapidly cooled and not fracture -- is proportional to f k E 55 Durability: Corrosion and Degradation of Materials ISSUES TO ADDRESS... • How does corrosion occur? • Which metals are most likely to corrode? • What environmental parameters affect corrosion rate? • How do we prevent or control corrosion? 56 THE COST OF CORROSION • Corrosion: -- the destructive electrochemical attack of a material. -- Ex: Al Capone's ship, Sapona, off the coast of Bimini. Photos courtesy L.M. Maestas, Sandia National Labs. Used with permission. • Cost: -- 4 to 5% of the Gross National Product (GNP)* -- in the U.S. this amounts to just over $400 billion/yr** * H.H. Uhlig and W.R. Revie, Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering, 3rd ed., John Wiley and Sons, Inc., 1985. **Economic Report of the President (1998). 57 ELECTROCHEMICAL CORROSION Ex: consider the corrosion of zinc in an acid solution • Two reactions are necessary: Zn Zn2 2e -- oxidation reaction: -- reduction reaction: 2H 2e H2 (gas) H+ Oxidation reaction Zn Zn2+ H+ Zinc flow of e 2ein the metal H+ H+ + H H+ H2(gas) H+ reduction reaction Acid solution Adapted from Fig. 17.1, Callister & Rethwisch 8e. (Fig. 17.1 is from M.G. Fontana, Corrosion Engineering, 3rd ed., McGrawHill Book Company, 1986.) • Other reduction reactions in solutions with dissolved oxygen: -- acidic solution O2 4H 4e 2H2O -- neutral or basic solution O2 2H2O 4e 4(OH) 58 STANDARD HYDROGEN ELECTRODE • Two outcomes: -- Electrodeposition H2(gas) Mn+ H+ ions H+ e- 25ºC e- ne - 2e - metal, M metal, M ne - e- Platinum e- Mn+ ions H+ 2e H+ H2(gas) Platinum -- Corrosion 25ºC 1M Mn+ sol’n 1M H + sol’n 1M Mn+ sol’n 1M H+ sol’n -- Metal is the anode (-) -- Metal is the cathode (+) o Vmetal 0 (relative to Pt) o Vmetal 0 (relative to Pt) Standard Electrode Potential Adapted from Fig. 17.2, Callister & Rethwisch 8e. 59 STANDARD EMF SERIES more anodic more cathodic • EMF series metal Au Cu Pb Sn Ni Co Cd Fe Cr Zn Al Mg Na K o Vmetal • Metal with smaller o Vmetal corrodes. +1.420 V • Ex: Cd-Ni cell +0.340 o o V < V Cd corrodes Ni Cd - 0.126 - 0.136 + - 0.250 V o = - 0.277 0.153V - 0.403 - 0.440 Cd Ni 25ºC - 0.744 - 0.763 - 1.662 1.0 M 1.0 M - 2.363 Cd 2+ solution Ni 2+ solution - 2.714 Adapted from Fig. 17.2, Data based on Table 17.1, Callister & Rethwisch 8e. - 2.924 Callister 8e. 60 CORROSION IN A GRAPEFRUIT Cu (cathode) Zn (anode) + H+ Zn 2+ 2e - reduction reactions 2H 2e H2 (gas) O2 4H 4e 2H2O H+ - H+ H+ oxidation reaction H+ Acid H+ Zn Zn2+ 2e H+ 61 EFFECT OF SOLUTION CONCENTRATION AND TEMPERATURE • Ex: Cd-Ni cell with standard 1 M solutions o VNio VCd 0.153 V - Cd + 25ºC Ni 1.0 M 1.0 M Cd 2+ solution Ni 2+ solution • Ex: Cd-Ni cell with non-standard solutions RT X o o VNi VCd VNi VCd ln nF Y - Cd + T Ni XM YM Cd 2+ solution Ni 2+ solution • Reduce VNi - VCd by -- increasing X -- decreasing Y -- increasing T n = #eper unit oxid/red reaction (= 2 here) F= Faraday's constant = 96,500 C/mol. 62 GALVANIC SERIES more anodic (active) more cathodic (inert) • Ranking of the reactivity of metals/alloys in seawater Platinum Gold Graphite Titanium Silver 316 Stainless Steel (passive) Nickel (passive) Copper Nickel (active) Tin Lead 316 Stainless Steel (active) Iron/Steel Aluminum Alloys Cadmium Zinc Magnesium Based on Table 17.2, Callister & Rethwisch 8e. (Source of Table 17.2 is M.G. Fontana, Corrosion Engineering, 3rd ed., McGrawHill Book Company, 1986.) 63 FORMS OF CORROSION • Stress corrosion Corrosion at crack tips • Uniform Attack when a tensile stress • Erosion-corrosion Oxidation & reduction Combined chemical attack and is present. reactions occur uniformly mechanical wear (e.g., pipe over surfaces. elbows). • Selective Leaching • Pitting Preferred corrosion of one element/constituent [e.g., Zn from brass (Cu-Zn)]. • Intergranular Corrosion along grain boundaries, often where precip. particles form. g.b. prec. attacked zones Fig. 17.18, Callister & Rethwisch 8e. Forms of corrosion • Galvanic Downward propagation of small pits and holes. Fig. 17.17, Callister & Rethwisch 8e. (Fig. 17.17 from M.G. Fontana, Corrosion Engineering, 3rd ed., McGraw-Hill Book Company, 1986.) • Crevice Narrow and Dissimilar metals are confined spaces. Rivet holes physically joined in the presence of an electrolyte. The Fig. 17.15, Callister & Rethwisch 8e. (Fig. 17.15 more anodic metal is courtesy LaQue Center for Corrosion Technology, Inc.) corrodes. 64 CORROSION PREVENTION (i) • Materials Selection -- Use metals that are relatively unreactive in the corrosion environment -- e.g., Ni in basic solutions -- Use metals that passivate - These metals form a thin, adhering oxide layer that slows corrosion. Metal oxide Metal (e.g., Al, stainless steel) • Lower the temperature (reduces rates of oxidation and reduction) • Apply physical barriers -- e.g., films and coatings 65 CORROSION PREVENTION (ii) • Add inhibitors (substances added to solution that decrease its reactivity) -- Slow oxidation/reduction reactions by removing reactants (e.g., remove O2 gas by reacting it w/an inhibitor). -- Slow oxidation reaction by attaching species to the surface. • Cathodic (or sacrificial) protection -- Attach a more anodic material to the one to be protected. Galvanized Steel Adapted from Fig. 17.23, Callister & Rethwisch 8e. Using a sacrificial anode Zn 2+ zinc zinc 2e - 2e steel e.g., zinc-coated nail steel pipe e- Cu wire Mg Mg 2+ anode Earth e.g., Mg Anode Adapted from Fig. 17.22(a), Callister & Rethwisch 8e. 66 SUMMARY • Metallic corrosion involves electrochemical reactions -- electrons are given up by metals in an oxidation reaction -- these electrons are consumed in a reduction reaction • Metals and alloys are ranked according to their corrosiveness in standard emf and galvanic series. • Temperature and solution composition affect corrosion rates. • Forms of corrosion are classified according to mechanism • Corrosion may be prevented or controlled by: -- materials selection -- reducing the temperature -- applying physical barriers -- adding inhibitors -- cathodic protection 67