Filtration - UniMAP Portal

advertisement

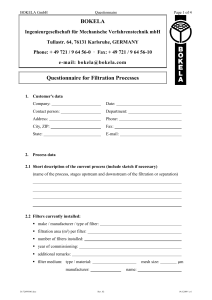

Filtration Learning objectives • Explain the basic types and mechanisms of filtration • Exploit the Darcy’s Law equation in order to solve problems for conventional and constant pressure cake filtration • Select filtration media and equipment to meet bioproduct processing requirement Introduction • Filtration is a solid-liquid separation where the liquid passes through a porous medium to remove fine suspended solids. • The main objective of filtration is to produce highquality drinking water (surface water) or highquality effluent (wastewater) and also for biopharmaceutical products Figure 1 Schematic diagrams for dead-end or conventional filtration. For dead-end filtration the thickness of the solids buildup increases and the permeate flux decreases with time, ultimately reaching zero. Filtration Filters use a filter cloth or some porous material along with applied pressure to push smaller particles through the filter, thus separating elements of the solution based on size. Filtration for biological materials is generally completed using batch filtration, rotary drum filtration, or ultrafiltration methods. Batch Filtration • Usually performed under constant pressure with a pump that moves the broth or liquor through the filter • Filter cake will build-up as filtration proceeds and resistance to broth flow will increase • The filter press is the typical industrial version of a batch vacuum filter, using a plate and frame arrangement • Can be used to remove cells, but does not work particularly well for animal cell debris or plant seed debris Filtration Rotary Drum Filtration • Solution is vacuumed upward where it crosses a filter septum removed by a positive displacement pump • Filter cake is removed after each rotation to give a fresh surface for filtration • Rotary vacuum filters can be used to efficiently remove mycelia, cells, proteins, and enzymes, though a filter aid or precoat of the septum may be necessary Ultrafiltration • Utilizes a membrane to separate particles that are much larger than the solvent used • Successful removal occurs in the partical size range of 10 solvent molecular diameters to 0.5 μ Filtration Principles • When a slurry containing suspended solids flow against a filter medium by the application of a pressure gradient across the medium, solids begin to build up on the filter medium • The buildup of solids on the filter medium is called a cake • This type of filtration is sometimes referred to as “dead-end” filtration” • Darcy’s law describes the flow of liquid through a porous bed of solids and can be written as follows: (1) V: volume of filtrate, t: time, A: cross-sectional area of exposed lilter medium, Δp: the pressure drop through the bed of solids (medium plus cake) µ0: the viscosity of the filtrate, R: resistance of the porous bed. Filtration Principles • In this case, R is a combination of the resistance Rm of the filter medium and the resistance Rc of the cake solids: (2) • It is convenient to write the cake resistance Rc in terms of specific cake resistance α as follows: (3) ρc: mass of dry cake solids per volume of filtrate. • Thus, the resistance increases with the volume filtered • Combining Eq. (1), (2) and (3), we obtain (4) Filtration Principles • For the case of zero filtrate at time zero, integration of this equation yields: (5) • The pressure drop is influence by α, the specific cake resistance • α can be increased if the cake is compressed • Cakes are typically compressible when cells and other biological materials are being filtered • The specific resistance of the cake is directly affected by Δpc, the pressure drops across the cake Filtration Principles • Studies have shown that the relationship between specific resistance and pressure drop commonly takes the form: (6) • where α’ and s are empirical constants. • The power s has been called the “cake compressibility factor” and has been found to range from zero for incompressible cakes such as sand and diatomite to near unity for highly compressible cakes Filtration Principles Figure 2 Filtration data for Streptomyces griseus broth with Δp = 2.0 bar. The filter medium was of cotton cloth, and diatomaceous earth filter aid was added to the broth. (Data from S. Shirato and S. Esumi, “Filtration of a culture broth of Streptomyces griseus” J. Ferment, Technol. (Japan), vol. 41, p. 87, 1963.) ;1] Example 1 Batch Filtration A Buchner funnel 8 cm in diameter is available for testing the filtration of a cell culture suspension, which has a viscosity of 3.0 cp. The data in Table E1 were obtained with a vacuum pressure of 600 mm Hg applied to the Buchner funnel. The cell solids on the filter at the end of filtration were dried and found to weigh 14.0 g. Determine the specific cake resistance α and the medium Resistance Rm. Then estimate how long it would take to obtain 10,000 liters of filtrate from this cell broth on a filter with a surface area of 10 m2 and vacuum pressure of 500 mm Hg. Example 1 TABLE E1 Example 1 Solution According to Equation (5), we can plot t/(V/A) versus V/A and obtain α from the slope and Rm from the intercept. We see that the data are reasonably close to a straight line. Figure E1 Plot of batch filtration data for the determination of α and Rm. Example 1 A linear regression of the data in this plot gives the following results (Figure E1): Example 1 From these values, we can calculate α and Rm: This is a typical value of Rm for a large-pore (micrometer-sized) filter. Example 1 To determine the time required to obtain 10,000 liters of filtrate using a filter with an area of 10 m2, we must make the assumption that α does not change at the new pressure drop of 500 mm Hg. We use Equation (5) and solve for time: We calculate the two components of this equation as follows: and finally Example 1 Thus, this filter is probably undersized for the volume to be filtered. In addition, from this calculation we see that at the end of the filtration, Therefore, the filter medium is contributing very little of the resistance to filtration, a typical situation in a lengthy dead-end filtration. Filtration Principles • For products that are recovered in the filtrate, it is often necessary to wash the filter cake with water or a salt solution to maximize the removal of dissolved product from the cake. • Frequently, the wash must be done with more than the volume of the liquid in the cake • This is because some of the product is in stagnant zones of the cake, and transfer into the wash liquid from these zones occurs by diffusion, which takes place at a slower rate than the convective flow of wash through the cake • Data for the washing of the filter cakes has been correlated by Choudhary and Dahlstrom using the following equation: (7) R’: weight fraction of solute remaining in the cake after washing (on the basis that R’ = 1.0 prior to washing), E: percentage wash efficiency, and N: volume of wash liquid per volume of liquid in the unwashed cake. Filtration Principles • Assuming that the liquid viscosity and the pressure drop through the bed solids are the same during the filtration of the solids, the washing rate per crosssectional area can be found from the filtrate flow rate per unit area given in Equation (4) at the end of the filtration • Thus, for negligible filter medium resistance for filtrate volume Vf at the end of time tf to form the cake, this yields (8) Filtration Principles • If Vw is the volume of wash liquid applied in time tw, then (9) • Using the definition of (dv/dt)V=Vf from Eq. (8), we obtain (10) • At the end of filtration, the integrated form of the filtration equation (Eq. 5), with Rm neglected, can be written (11) • Substituting this expression for Vf/A in Eq. (10) and simplifying gives (12) Filtration Principles • From Eq. (11) and (12), the ration of tw to tf is (13) • It is helpful to write tw/tf in terms of n, the ration of the volume Vw of wash liquid to the volume Vr of residual liquid in the cake: (14) • where f is the ratio of Vr to the volume Vf of filtrate at the end of filtration. • The ratio f can be determined by a material balance • Thus, for a given cake formation time tf, a plot of wash time tw versus wash ratio n will be a straight line Example 2 Rotary Vacuum Filtration It is desired to filter a cell broth at a rate of 2000 liters/h on a rotary vacuum filter at a vacuum pressure of 70 kPa. The cycle time for the drum will be 60 s, and the cake formation time (filtering time) will be 15 s. The broth to be filtered has a viscosity of 2.0 cp and a cake solids (dry basis) per volume of filtrate of 10 g/liter. From laboratory tests,the specific cake resistance has been determined to be 9 x 10 cm/g. Determine the area of the filter that is required. The resistance of the filter medium can be neglected. Example 2 Solution We can use the integrated form of the filtration equation, Equation (5), with Rm = 0: We solve for A2 to obtain In applying this equation, it is helpful to focus on the area of the drum that is submerged, which is where the cake is being formed and where filtrate is being obtained. Thus, A is the area of that part of the drum that is submerged. We can calculate the volume of filtrate that needs to be collected during the cake formation time of 15 s: Example 2 We use this volume of filtrate with t = 15 s in the equation for A2 to obtain The area A’ of the entire rotary vacuum filter can be calculated from the cake formation time and the total cycle time as This is a medium-sized rotary vacuum filter, with possible dimensions of 1.0 m diameter by 1.0 m long. Example 3 Washing of a Rotary Vacuum Filter Cake For the filtration in Example 2, it is desired to wash a product antibiotic out of the cake so that only 5% of the antibiotic in the cake is left after washing. We expect the washing efficiency to be 50%. Estimate the washing time per cycle that would be required. Solution Example 3 From Equation (7) for the washing efficiency of a filter cake where R’ is the weight fraction of solute remaining in the cake after washing (on the basis of R’ = 1.0 before washing), E is the percentage wash efficiency, and n is the volume of wash liquid per volume of liquid in the unwashed cake. Substituting R’ = 0.05 and E = 50% into this equation gives From Equation (14), the relationship between the washing time tw, and the cake formation time tf is given by where f is the ratio of volume Vr of residual liquid in the cake to the volume of filtrate Vf after time tf. Example 3 Thus, we need to estimate the volume of residual liquid in the filter cake to determine tw. At the end of the 15 s cake formation time, Assuming the cake is 70 wt% water, which is typical for filter cakes, we find Thus, From this result, the estimated washing time is 20% of the cake formation time. Filter Media and Filter Aids 1. Filter media • The filter media must remove the solids to be filtered from the slurry and give a clear filtrate • The pores should not become plugged so that the rate of filtration becomes too slow • The filter medium must allow the filter cake to be removed easily and cleanly • Some widely used filter media are woven fabrics (e.g. woven heavy cloth, glass cloth, etc, no leaching of components are allowed, size of particle trapped: 10 μm), metal fabrics or screens (e.g. nickel,copper, etc, good resistance to leachingand corrosion required, size of particle trapped: 5 μm), and rigid porous media (e.g. sintered stainless steel, silica, pocelain, etc) • For sterile filtration, commonly used are asymmetric membrane filter (cellulose esters or other polymers, pore size: 0.22-0.45 μm) Filter Media and Filter Aids • 2.Filter aids • Certain filters aids may be used to aid filtration • Can be either added directly to the feed or applied to the filtration equipment • These are often diatomaceous earth or kieselguhr and perlite which is composed primarily of silica. • Also used are wood cellulose and other inert porous solids • Can be use as a precoat before the slurry is filtered to prevent gelatinous-type solids from plugging the filter medium and also give clearer filtration • Can also be added to the cake during filtration to increases the porosity of the cake and reduces resistance of the cake during filtration Types of Filtration Equipment 1. Plate-and-frame filter presses • • • • Consist of plates and frames assembled alternately with a filter cloth over each side of the plates The plates have channels cut in them so that clear filtrate liquid can drain down along each plate The feed slurry is pumped into the press and flows through the duct into each of the open frames so that slurry fills the frames The filtrate flows through the filter cloth and the solids build up as a cake on the frame side of the cloth Types of Filtration Equipment 2. Leaf filters • Developed for larger volumes of slurry and more efficient washing • Each leaf is a hollow wire framework covered by a sack of filter cloth • The slurry enters the tank and is forced under pressure through the filter cloth, where the cake deposits on the outside of the leaf • The wash liquid follows the same path as the slurry. Hence, the washing is more efficient than the through wishing in plate-andframe filter presses Types of Filtration Equipment 3. Continuous rotary filters (a) continuous rotary vacuum-dryer filter • Filters, washes and discharges the cake in continuous, repeating sequence • covered with a suitable filtering medium • rotates and an automatic valve in the center serves to activate the filtering, drying, washing, and cake-discharge functions in the cycle • The filtrate leaves through the axle of the filter (b) continuous rotary disk filter • consist of concentric vertical disks mounted on a horizontal rotating shaft • operates on the same principle as the vacuum rotary-drum filter • Each disk is hollow and covered with a filter cloth and is partly submerged in the slurry • The cake is washed, dried and scraped off when the disk is in the upper half of its rotation Types of Filtration Equipment (c) continuous rotary horizontal filter • This type is a vacuum filter with the rotating annular filtering surface divided into sectors • As the horizontal filter rotates, it successively receives slurry, is washed, is dried and the cake is scraped off