The Fundamental Reasons Behind The Failure Of ERP System

advertisement

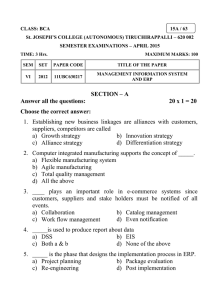

The Fundamental Reasons Behind The Failure Of ERP System SYSM 6309 Advanced Requirements Engineering By Shilpa Siddavvanahally ERP In ERP solution there is only one database that is used by all departments, such as Sales, Production, Finance and Accounting, Maintenance and Engineering, Purchasing, etc. ERP applications contain several modules. Each module consists of the best business practice that can be implemented for the company. ERP helps to break down barriers between departments within a company. By utilizing an ERP system, all departments have access to the up-todate information that is needed to operate smoothly within any manufacturing environment. IMPORTANCE OF ERP ERP takes a customer order and provides a software road map for automating the customer order into the path and fulfilling it. When a customer service representative enters a customer order into an ERP system, he has all the information necessary to complete the order For example: The customer's credit rating, order history from the finance, the company's inventory from the warehouse module and the shipping dock's trucking schedule from the logistics module FOR EXAMPLE: Customer . Customer Reps PROBLEM The biggest mistake from the electronics company was not realizing the issue in the early stages and spending 3 million dollars over a period of 3 years without any accomplishment Lack of top management involvement is one of the reason for the failure of ERP implementation. Inadequate definition of quality functional requirements was a major problem PROBLEM Poor ERP package selection because of not defining the requirements systematically. As the requirements defined by the electronics company were not optimum, the consultants couldn’t come up with a optimum solution. SOLUTION Identifying the right requirements will reduce most of the problems in an ERP implementation. Internal auditors can help organizations lay the foundation for any new initiative with their knowledge of the company, its requirements and business processes. Top management involvement in communicating the importance of ERP implementation will help in gaining the support and commitment of employees. Proper project planning which has a comprehensive scheduling, budget management, resource allocation, quality management and cost control will increase the success ratio of implementation. A SUCCESSFUL DEPLOYMENT OF AN ERP SYSTEM: A CASE STUDY OF A SMALL GREEK COMPANY A BRIEF OVERVIEW The company imports and supplies the Greek market with a wide range of products The Greek financial crisis and the competition from global market provided an opportunity to adopt an ERP system. In order to improve its services, the company decided to upgrade its inventory management process Introduction of an ERP solution seemed to be appropriate so that it can set up a common platform for accounting, inventory and materials management to communicate. SUCCESS FACTOR • • • Consistent support of top management Had clear goals and objectives that were essential to guide ongoing organizational efforts for ERP implementation. Explained and justified the significance of the project to their employees. • Consultants undertook the directorship of the project and project team worked very closely with the consultants • Selected package was a user-friendly one and users were very satisfied with it . • • Training during technology implementation influenced user attitudes, performance and acceptance of the new system The company tried to introduce a new system, fortunately not “all-atonce”, rather in a span of 8 months of preparation. A CASE STUDY ON HERSHEY'S ERP IMPLEMENTATION FAILURE Why Hershey’s Decided to implement ERP : Hershey’s redesigned the whole process keeping customer in mind, to enhance their competitiveness, and to enhance their customer service. Hershey’s need of an efficient and reliable logistics system to cater large number of seasonal requirement Decided to switch over to the ERP system by April 1999. The software from Manugistics was to provide for transport management, production, forecasting and scheduling. The software from Siebel was to support Hershey in managing customer relations and in tracking the effectiveness of the company's marketing WHAT WENT WRONG? WHAT WENT WRONG? SQUEEZED DEADLINES Project originally scheduled for 4 years Company forced the implementation to 30 months WRONG TIMING The company went live at their busiest time Released the solution just before the Halloween BIG- BANG IMPLEMENTATION To quicken the implementation, Hershey's opted for big bang implementation Simultaneously implemented a customer relations package and a logistics package even without testing some of the modules Orders from many retailers and distributors could not be filled, even though Hershey's had the finished product stocked in its warehouses. LESSON LEARNED Paying close attention to scheduling, careful timing and planning of the project are important Major enterprise applications (CRM, Logistics, etc.) should be implemented one at a time Top management should keep a close watch and work for a common goal QUESTIONS