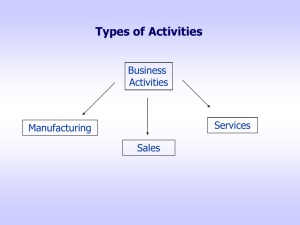

Types of Manufacturing Presentation

advertisement

Types of Manufacturing Advanced Design Applications Custom Made to Mass Production • The type of manufacturing system utilized in a products development varies depending on many factors. One important factor that helps determine the manufacturing system is the number of products to be produced. Other factors include number of variations of the product, materials availability, and processes needed to manufacture. Main Categories of Manufacturing • Prototype Manufacturing • Job Shop Manufacturing • Mass Production • Project Type Manufacturing Prototype Manufacturing • Widely used in todays manufacturing environments • Most expensive type of manufacturing • Used before actual production of “customer” products • Can be a physical model made from actual or simulated materials • Rapid Prototyping • 3D Printing Job Shop Manufacturing • Used by small companies and shops • Small orders; small batches of products • May be a sub contractor for a larger manufacturing project • Light assemblies for cars • Can switch between jobs quickly • Shops may specialize in a manufacturing process – machining, casting, molding Mass Production • Products made in large quantities • High demand products • Assembly line production • Developed in 20th century by Henry Ford Project Type Manufacturing • Used for big projects • Expensive projects; products last a long time • Uses many sub contractors for assemblies • Usually government projects • Navy ships • Assignment DIRECTIONS – Use the Internet to research the following methods of manufacturing. For each method explain the major idea behind it (What is it; How does it work), the benefits (advantages), and the drawbacks (disadvantages). Compile your answers into a PowerPoint presentation. Document all sources used. 1. 2. 3. 4. 5. 6. 7. 8. 9. Just in Time (JIT) Flexible Manufacturing Systems (FMS) Group Technology (GT) Green Manufacturing Lean Manufacturing Computer Integrated Manufacturing (CIM) Computer Aided Manufacturing Concurrent Engineering Nanomanufacturing