t_procedure 118 - fall protection

advertisement

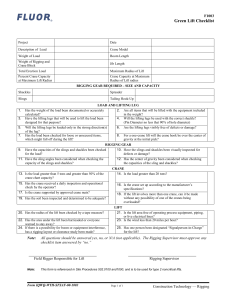

Contractor Safety Number: CSM - 019 Title: Critical Lift Template Revised: 08/21/2013 1. Applicability CO2 KMC Natural Gas Products Pipeline Terminals All Projects & Contractors 2. Scope The Crane Critical Lift Template provides an in-depth evaluation and plan for all heavy and/or complicated crane lifts and should be completed before attempting the lift. 3. Definitions 1. Competent Person – OSHA defines a competent person as "one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them". 2. Qualified Person – OSHA defines a qualified person as “one who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training and experience, has successfully demonstrated his ability to solve or resolve problems relating to the subject matter, the work, or the project. 3. Critical Lift: A critical lift has one or more of the following conditions: Load is over 75% of the crane’s rated capacity for current configuration. Load is more than 20 tons. Lift is over operating systems (charged electrical equipment, pipelines, etc.) Lift requires the use of two (2) or more cranes. Hoisting of contractor employees on a suspended work-platform or man basket. 4. Contractor’s Construction Supervisor: The contractor’s supervisor is responsible for the completion of the critical lift. Page 1 of 7 Contractor Safety Number: CSM - 019 Title: Critical Lift Template Revised: 08/21/2013 5. Crane Operator: The operator who will be operating the crane and making the lift. 6. Rigging Supervisor: The contractor’s supervisor responsible for planning and executing the rigging being used for the critical lift. 7. Contractor’s Safety Manager: The contractor’s site safety manager. 8. Contractor’s Construction Manager: The contractor’s construction manager responsible for the contractor’s daily construction activities at the site. 4. Requirements Review the “Critical Lift Plan” at the lift site just prior to making the lift. Critical Lift Plan documentation The lift plan must include: o Current certification of the crane operator o Type of crane(s; rubber tire, track stationary, does the crane require on site assembly, including a copy of the most current certification o Is a load test required? o Type rigging that will be used, including rated capacity o Most recent annual inspection records, which must include the name of the person conducting the inspection and qualifications o Conditions that may delay the lift o Overhead hazards power lines, guidelines etc. o Soil/ground conditions [are the any subsurface vaults USTs, duct-banks storm water sewers, etc. o A Communication Plan – will radio or hand signals be used, how will other affected stakeholders in the area notified o Load details o Will tag lines be used? If yes: how will they be used, is there sufficient room, what are the hazards etc. o Contingency plan what if something goes wrong? Mechanical failure, incorrect load calculation resulting in exceeding 90% of crane capacity o Written calculations of the lift, including the configuration of the rigging and load. Safety precautions necessary for all employees in the area, including personnel employed by other contractors. All lifts out of water require additional calculations. Review of crane inspection and maintenance documentation to ensure they are current. Page 2 of 7 Contractor Safety Number: CSM - 019 Title: Critical Lift Template Revised: 08/21/2013 A Pre-job briefing including all employees involved in making the lift. The briefing of all other contractor’s superintendents who have employees working within the area, if any. Review and update of all associated JHA’s/JSA’s. The contractor shall comply with all Federal, State, and Local laws and regulation regarding the inspections, maintenance, and operation of the cranes within their fleet. The OSHA rule prohibits hoisting personnel by crane or derrick except when no safe alternative is possible. Based on the review of the record, OSHA determined that hoisting with crane- or derrick-suspended personnel platforms constitutes a significant hazard to hoisted employees and must not be permitted unless conventional means of transporting employees are not feasible or unless they present greater hazards. Page 3 of 7 Number: CSM - 019 Title: Critical Lift Template Revised: 08/21/2013 Contractor Safety CRITICAL LIFT PLAN Project Name: Location: Date: Company: Submitted By: Approved By: Crane Manufacturer: Model Number: Crane Inspection Date: Weather Condition: Description of Load: Boom Length: Boom Angle: Degree of Swing: Jib Length: Offset/Type: Max Operating Radius: Crane Rated Cap: Total Weight: Percent of Chart: Classification (check all that apply) Load is over 75% of crane’s capacity for current configuration Lift is more than 20 tons Lift is over operating systems(charged electrical equipment, pipelines, etc) Lift uses two (2) or more cranes Hoisting of Contractor employees on a suspended work-platform/man-basket Signatures Construction Supervisor: Construction Manager: Safety Manager: Crane Operator: Rigging Supervisor: Page 4 of 7 Number: CSM - 019 Title: Critical Lift Template Revised: 08/21/2013 Contractor Safety Pre-Lift Meeting Attendees Printed Name Signature Page 5 of 7 Number: CSM - 019 Title: Critical Lift Template Revised: 08/21/2013 Contractor Safety LIFT DETAIL SHEET 1 Weight Jib Weight of Equipment Weight of Headache Ball Weight of Load Block Weight of Lifting Bar Lbs. Lbs. Lbs. Lbs. Weight of Slings & Shackles Weight of Jib Weight of Cable (Load Fall) Allowance for Unaccounted Material in Equip. (10% of Equip Weight) Other (Water): Total Weight Source of Load Weight Lbs. Lbs. Lbs. Lbs. Lbs. Lbs. (Name Plate, Drawings, Calculated): Weight Verified By: Crane Type of Crane: Crane Capacity Lifting Arrangement: Max Distance Center Load to Center Pin Lbs. Stowed: Length of Jib Angle of Jib Rated Cap of Jib (from Chart) Sizing of Slings/Shackles Sling Selection Ft. Deg. Lbs. Type of Arrangement Number of slings in hookup Cert. Attached or Number Sling Length Slings Rated Capacity of Slings Shackle Selection Lbs. Ft. Capacity Shackles attached to load by Number of Shackles Tons Cert Attached or Number Ft. Length of Boom Ft. Angle of Boom @Pickup Deg. Angle of Boom @Set Deg. Rated Capacity of crane under most severe lifting conditions: Over Rear Lbs. Over Front Lbs. Over Side Lbs. Rate Capacity of Crane for Lift Lbs. Maximum Load on Crane Lift is % of Crane’s Rated Capacity Erected: Crane Placement Yes No Smooth Solid Foundation in area? Electrical Hazards in area? If “Yes” Explain: Obstructions/Obstacles to Lift/ Swing? If “Yes” Explain: Lbs. Underground piping/Cables? If “Yes” Explain: Page 6 of 7 Number: CSM - 019 Title: Critical Lift Template Revised: 08/21/2013 Contractor Safety LIFT DETAIL SHEET 2 Pre-Lift Check List Questions Yes No Questions Yes Matting Acceptable? Outriggers Fully Extended? Crane in Good Condition? Adequate Awing Room? Tag line Used? Experienced Operator? Experienced Flagman Designated? Experienced Rigger? Head Room Checked? Maximum Counterweight Used? Load Chart in Crane? Wind Conditions? Crane Inspected by: Date: Functional Test of Crane By: Date: Diagram Crane & Load Placement (Draw in Space Below or attach copy) No Diagram Rigging Configuration (Draw in Space below or attach copy) Special Instructions or Restrictions for Crane, Rigging, Lift, Etc. (a) MULTIPLE CRANE LIFTS REQUIRE A SEPARATE LIFT PLAN FOR EACH CRANE. (b) ANY CHANGES IN THE CONFIGURATION OF THE CRANE, PLACEMENT, RIGGING, LIFTING SCHEME, ETC. OR CHANGES IN ANY CALCULATIONS REQUIRE THAT A LIFT PLAN BE DEVELOPED. Page 7 of 7