disinfection technologies for small water systems

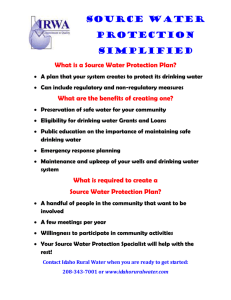

advertisement

DISINFECTION TECHNOLOGIES FOR SMALL WATER SYSTEMS Silver Falls 24 May 2006 1 Some Presentation Topics (not necessarily in order or complete) Why do we Disinfect? What, When & Where do we disinfect: Chlorine & Other Common Disinfectants Types of Chlorine Chemistry Application / Dosages Contact Time v. Residual Cl How to disinfect well – e.g. calculating CTs, & How to disinfect a well. 2 DHS Drinking Water Program Purpose of Disinfection Inactivation of Pathogens Bacteria – Coliforms, Campylobacter Viruses – Norwalk, Hepatitis A/B Giardia (parasitic protozoa) Cryptosporidium (parasitic protozoa) Regulatory Requirements Residual Maintenance vs. Disinfection Why does your system use disinfectant?? 3 DHS Drinking Water Program Common Disinfectants (In order of prevalence) CHLORINE Ultraviolet Light (UV) Ozone (O3) Mixed Oxidants (MIOX) Chloramines (Cl2 plus ammonia) DHS Drinking Water Program 4 Chlorine Types (All must be NSF approved): Gas: Solid: Liquid: Larger systems, safety concerns, 99.5 % available chlorine Calcium Hypochlorite (Ca(OCl)2) 15% to 70% available chlorine Sodium Hypochlorite (NaOCl) 5% to 15 % available chlorine Common bleach = 5.25% (Shorter half-life at higher concentrations) 5 DHS Drinking Water Program Chlorine Chemistry Tips Chlorine + Water = Hypochlorous acid (HOCl), a strong disinfectant. Depending on water temperature and pH, this acid may disassociate to hypochlorite ion (OCl-), a less effective disinfectant. (HOCl is eighty times more potent than OCl-) At pH of 7.5, acid to ion ratio is 50/50 Colder water temps and high pH make disinfection less efficient. 6 DHS Drinking Water Program Relative Amount of Hypochlorous Acid & Hypochlorite Ion 1 OCl- HOCl Fraction of Free Chlorine 0.8 0.6 0.4 0.2 0 3 4 5 6 7 pH 8 9 10 11 12 7 DHS Drinking Water Program Effects of pH on Residual Type Free Chlorine 50% OCl- 90% OCl- 50% HOCl 10%HOCl pH 7.5 8.5 8 DHS Drinking Water Program Strengths of Residual Chlorine Compounds OCl(80x weaker) Chloramines (combined) (60x – 200x weaker) Increasing Strength HOCl 9 DHS Drinking Water Program Interfering Agents Iron (Fe) Manganese (Mn) Turbidity 10 DHS Drinking Water Program When to Increase Chlorine Dosage Increase Chlorine Dose When You Have: Increase in: • pH • Turbidity • Fe & Mn Decrease in: • Temperature 11 DHS Drinking Water Program Calculating Chlorine Residual Chlorine Dose - Chlorine Demand Chlorine Residual 12 DHS Drinking Water Program Calculating Chlorine Residual (continued) Free Chlorine Residual + Combined Chlorine Residual Total Chlorine Residual 13 DHS Drinking Water Program Breakpoint Chlorination Curve 100 100 88 minutes 90 83 minutes 80 70 Zone 1 Zone 2 Combined Chlorine Only e.g., NH2Cl Destruction of Combined Residual Chlorine 60 50 40 Zone 3 60 Free Chlorine 40 30 20 Time for 99% inactivation of B. metiens spores [minutes] mg Free Chlorine Residual [ /L] 80 20 Breakpoint! 10 2.7 minutes 0 20 40 60 80 100 Chlorine Dose [ mg/L] 120 140 0 160 14 DHS Drinking Water Program Same Breakpoint Curve (with Nitrogen Compounds) 15 DHS Drinking Water Program Disinfection Contact Time v. Residual Maintenance What’s the Difference?? Generally speaking, we require: Disinfection with Contact Time for contaminated Sources. Residual Maintenance for Distribution. 16 DHS Drinking Water Program Chlorine Residual Measure free chlorine residual daily. Must be detectable everywhere at all times. High levels of iron, manganese, or turbidity will increase chlorine demand. Use DPD-type test kit (colorimeter/digital) 17 DHS Drinking Water Program Why Is Residual Maintenance NOT “Disinfection”? Cl Cl 0.2 ppm Cl residual throughout distribution system Cl Cl Cl 18 DHS Drinking Water Program Why Isn’t Residual Maintenance “Disinfection”? Disinfection requires Contact Time Contamination Point 19 DHS Drinking Water Program Chlorine Applications Continuous Disinfection Must be proportional to flow Shock Disinfection One-time dose Well or reservoir disinfection Repairs 20 DHS Drinking Water Program Common Chlorine Doses 0.2 to 1.0 mg/L in distribution system Max allowable = 4.0 mg/L Using bleach (5.25% chlorine): 1 cup bleach/100 gal water = 25 ppm 1/3 cup bleach/1000 gal water = 1 ppm Reservoir cleaning: 10 ppm for 24 hours or 50 ppm for 6 hours 21 DHS Drinking Water Program Well Disinfection - Shock 50 ppm for 24 hours Mix chlorine with water before introducing into well Re-circulate if possible 22 DHS Drinking Water Program Well Disinfection Dose (cont’) 6” diameter well = 1.5 gallons/ foot of depth Need well depth & static water level (SWL) 2 cups 5% bleach / 100 gallons water = 50 ppm Pump to waste. 23 DHS Drinking Water Program Shock Chlorination Example Well = 200 feet deep; SWL = 120 feet 80’ of water in 6” casing = 120 gallons of water in the well Since 2 cups of 5% bleach per 100 gallons of water will produce 50 ppm, use slightly over 2 cups. Flush after 24 hours. 24 DHS Drinking Water Program Disinfection of Storage Tanks May be necessary if sampling indicates Access to tank (sight only, arm’s length, or physical entry) Tank drainage Where to? Discharge may be regulated Pump out if no drain 25 DHS Drinking Water Program Disinfection Doses for Storage Tanks (per AWWA Std. C652 and OAR 333) 10 ppm for 24 hours (with tank full) 50 ppm for 6 hours “ “ 200 ppm sprayed or brushed on interior surfaces of empty tank 26 DHS Drinking Water Program Chlorine Equipment Gas cylinders (and safety equipment) Chemical feed pumps Tablet dispensers / Erosion chlorinators Test kit DPD-type, color wheel or digital Orthotolodine (OTD) method or test strips not acceptable 27 DHS Drinking Water Program Chemical Feed Pumps Positive-displacement type (LMI, BlueWhite) Peristaltic (Stenner) Meter-driven (no electricity) 28 DHS Drinking Water Program LMI Feed Pump 29 DHS Drinking Water Program Wallace & Tiernen Feed Pump 30 DHS Drinking Water Program SCBA 31 DHS Drinking Water Program Proper Storage 32 DHS Drinking Water Program On-site Hypochlorite Generator NaOCl 100% SALT 33 DHS Drinking Water Program “Electrocution” Chamber 34 DHS Drinking Water Program Disinfection “CT Values” Definition: CT values are a measurement of the effectiveness of chlorine disinfection against bacteria, viruses, and protozoa. Concentration * Time = C*T 35 DHS Drinking Water Program CT Calculation CT = CT = [mg/L] X [minutes] = a number (no units expressed) Cl2 residual multiplied by contact time Example: 0.2 mg/L times 30 minutes CT = 6 36 DHS Drinking Water Program The Magic Number 6 CT required = 6 30 minutes * 0.2 ppm Cl Assumptions: Water Temperature ≥ 10oC (50oF) 37 DHS Drinking Water Program Required CT Values GW vs. SW Groundwater – Minimum CT = 6 Adequate for bacteria / virus kill Surface Water – Required CT varies with: pH, temp, and log-inactivation requirement 38 DHS Drinking Water Program Disinfection Contact Time (not to be confused with CT Calculation) Determined by Tracer Study or interim estimate Time = “effective” volume of contact chamber/flow Time = [minutes] = [gal] / [gpm] Pipe flow is ideal I.e., 100% credit for pipe volume Storage tanks likely have short-circuiting 39 DHS Drinking Water Program How Do You Really Measure Contact Time? T = V/Q 1. Determine peak demand flowrate Does system have an effluent flowmeter? 2. Look at the configuration of system. 3. Make estimate based on tank configuration & length of pipe Assume 10% of tank volume if unknown. 4. Calculate contact time using effective tank volume and effluent flowrate. 40 DHS Drinking Water Program Chlorination Concerns Disinfection by-products (DBPs) THMs and HAA5s DBP production encouraged by: High chlorine levels Long contact time Warm weather High source water TOC 41 DHS Drinking Water Program UV 42 DHS Drinking Water Program Ultraviolet Light Effective non-chemical disinfectant Suitable for small systems with few distribution lines Must meet plan review requirements: Minimum dosage 38 mWsec/cm2 Intensity monitor Automatic shut-off 43 DHS Drinking Water Program UV Pros & Cons Advantages: No chemicals, therefore no DBP’s No contact time required Simple Low operation & maintenance cost Disadvantages: No residual that protects distribution system 44 DHS Drinking Water Program Ozone (O3) Disinfection and taste/odor control Produced by electricity and air or pure O2 Inactivates Cryptosporidium Must be generated on-site Leaves minimal disinfectant residual Costs 4 times more than conventional disinfection, yet cheapest LT2 option 45 DHS Drinking Water Program Onsite O3 Generation Liquid O2 46 DHS Drinking Water Program Demo SS Injection w/ Nozzles 47 DHS Drinking Water Program MIOX “Mixed Oxidants” – mostly hypochlorite, ozone, and peroxides Produced on-site Requires electricity, rock salt, and water Special equipment needed, difficult for small systems Produces less DBPs 48 DHS Drinking Water Program MIOX Process 49 DHS Drinking Water Program MIOX Salt for Brine Solution 50 DHS Drinking Water Program MIOX Manifold 51 DHS Drinking Water Program PLAN REVIEW Required for ALL disinfection projects. NSF certification Contact regional engineer for specifics If don’t know whether PR was done: Ask! 52 DHS Drinking Water Program Questions??? Start Talking. 53 DHS Drinking Water Program