Enterprise information systems project implementation: A case study

Enterprise information systems project implementation: A case study of ERP in Rolls-Royce

Case Study published in International journal of production economics (2004)

Presented by Tim Moir

Bus550

June 3, 2013

The rise of Enterprise

Resource Planning systems

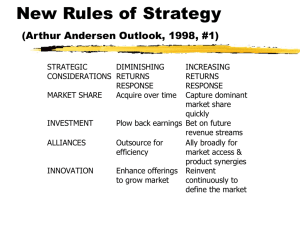

The global economy requires internationalization of operations

Requires flexibility

Decentralized operations

Managing globally

What does ERP do?

Increase the efficiency of an organization

Integrates separate functions such as manufacturing, finance, procurement, distribution into one system

Allows standardization of information across the entire enterprise, Information only entered once

Key Benefits

Business process automation

Timey access to management information

Improvement in the supply chain via the use of E-communication and E-Commerce

Implementation

The biggest risk associated with a ERP is the implementation

Must be managed as an organizational change rather then a software installation

The way a company operates must be changed to make the implementation successful

Organizational resistance must be managed

ERP is very adaptable but not malleable

Bridge software to legacy systems

Rolls-Royce Pre-ERP

New acquisitions lead to dramatic increase in size

Global company

Facilities in 14 countries by 1995

New organizational structure in 1998 to better meet customer needs

1500 systems, mostly internally developed

Expensive to create, difficult to manage

Data not accurate, consistent or accessible

In 1996 IT was outsourced to EDS

Rolls-Royce Implementation

Project

EDS provided the management team of specialists

Key – SAP Consultants

Project team is broken down into smaller segments

Each Operational Business Unit (OBU) has own planning team

Responsible for implementing working changes and training

Problems:

Cultural

Business

Technical

Cultural Problems

Need to ensure high acceptance across all areas of the company

Illustrate improvements made by the company as a whole

Training split into two separate groups

SAP specialists conducted technical training

SAP specialist trained expect users

Other end-users were trained internally with EDS consultants

Training used demonstrations within the workplace, info meetings, and presentations for all 10,000 employees

Business Problems

In order to ensure ERP works successfully, the business practices must fit the system

The internal business process had to be redesigned

Consisted of four steps

(1) Mapping the current process

(2) Identify issues / problems in the mapping

(3) Compare the mapping and problems with ERP process to identify issues in the new system

(4) Re-mapping to bring process inline with ERP

Why not make changes to ERP system?

Technical Problems

Key issue has been the accuracy of data

Data from Legacy systems needed to be upload

Data duplication major concern

Systematic process of taking old systems offline

Customer user interfaces created to bridge data

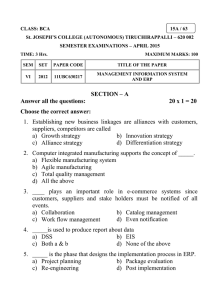

Nine principal business processes

Business Process Model

Release Strategy

Implementation team had to define a release strategy for the entire project

Items to consider:

Third party software to be accredited by SAP

Business reports had to be justified and developed

Data had to be identified, validated, cleaned, loaded, and archived

Additional Hardware needed (1000 new PC’s, 6000 licenses, servers)

Release Strategy

Phase 1 – Strategy and Direction

Intense Study during Q1 of 1998

Determine scope of project

Outline Plan

Determine Cost

Steering Committee for financial guidance

ERP Core Team was formed to oversee implementation process

Phase 2 Planning Analysis &

Convergence / Early Development

Created a detailed plan

Protégé system installed

Series of “High Level Process” workshops to discuss various business processes (involved 200 employees)

Another set of workshops “Business Simulation” (involved

300 employees) to forge relationship with ERP core team

Next steps included:

Preliminary design review

High level review

Critical design review

Implementation realization

Technical/Operation review

Post implementation review

Project Changes

Significant timing change made during Phase 2 – The implementation phases (Wave 1 and Wave 2 were deferred for six months)

Changes due to:

Allow more time to prepare, train, and clean up data

Allow 5 additional months for pilot running and early development

Allow additional time for completion of projects needed for which ERP is dependent

Resolve difficulties with ERP at RR Allison division

Phase 3 Implementation

The implementation phase was to large to be carried out at once

Broken into Wave 1 and Wave 2

Wave 1 involved replacing the legacy systems currently in place with new systems

End of Wave 1 involved a pilot project at one RR facility

Successful Pilot project allowed full Go-Live company-wide one year later

Phase 3 Implementation

Wave 2 lasted about one year in length

Not started until completion of Wave 1

Concerned engine assembly, spares, logistics and human resources

Legacy were “read-only”

Once the ERP showed to work properly, old systems phased out

Changes during Implementation phases involved legacy systems.

Changes planned in a number of suites

Suites 1, 2, 3

In order to handle the adaption of the ERP from the “legacy systems” a three step process

Suite 1

Plan the supply chain

Master schedule key program

Suite 2

Plan and schedule the factory

Schedule the shop

Plan 3

Operate the factory

ERP Pilot

3 months

Facility known a “number 4 shop” selected

Only produced 280 parts

Low numbers involved

Used as a test of the ERP system to demonstrate:

Business principles

Processes

Procedures

Role definitions and behaviors (including new roles)

Software, hardware, data transfers

Additional pilots

Pilot projects

System testing and user acceptance

Creating ownership of process

Testing, Testing and more Testing

Data verification

Typical going live issues:

User authorization

Processing delays

Data variances

System processing

Go-Live

Transferring legacy data

Stable environment for 10 weeks

Changes in data need to add to new system

Data can not be carried over and must start fresh

Old systems shifted to read-only

Constant monitoring of system to ensure proper operations

System overview

Project risks

Possible failure to align goals within organization

IT Hardware issues before or during implementation

Failure to provide adequate support

Resistance of change

Change not properly understood

Incomplete training

Data load issues

Project not given adequate priority

Maintenance issues

Financial data issues

Questions

What conditions let to the rise of the ERP?

(a) Global marketplace

(b) Decentralized operations

(c) Business flexibility

(d) All of the above

What is the biggest risk associated with ERP?

(a) Costs

(b) Implementation

(c) Strategy

(d) None of the above

Final Question

Which of the following was not identified as a key problem

(A) Cultural

(B) Business

(C) Procedural

(D) Technical