Bin and Hopper Design

advertisement

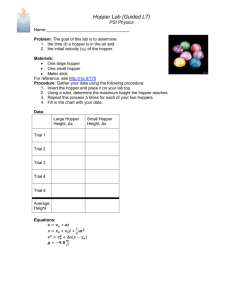

Bin and Hopper Design Karl Jacob The Dow Chemical Company Solids Processing Lab jacobkv@dow.com 3/17/00 KVJ 1 The Four Big Questions What is the appropriate flow mode? What is the hopper angle? How large is the outlet for reliable flow? What type of discharger is required and what is the discharge rate? 3/17/00 KVJ 2 Hopper Flow Modes Mass Flow - all the material in the hopper is in motion, but not necessarily at the same velocity Funnel Flow - centrally moving core, dead or non-moving annular region Expanded Flow - mass flow cone with funnel flow above it 3/17/00 KVJ 3 Mass Flow D Does not imply plug flow with equal velocity Typically need 0.75 D to 1D to enforce mass flow Material in motion along the walls 3/17/00 KVJ 4 Funnel Flow “Dead” or nonflowing region 3/17/00 KVJ 5 Expanded Flow Funnel Flow upper section Mass Flow bottom section 3/17/00 KVJ 6 Problems with Hoppers Ratholing/Piping 3/17/00 KVJ 7 Ratholing/Piping Stable Annular Region 3/17/00 KVJ 8 Problems with Hoppers Ratholing/Piping Funnel Flow 3/17/00 KVJ 9 Funnel Flow -Segregation -Inadequate Emptying 3/17/00 KVJ Coarse Fine Coarse -Structural Issues 10 Problems with Hoppers Ratholing/Piping Funnel Flow Arching/Doming 3/17/00 KVJ 11 Arching/Doming Cohesive Arch preventing material from exiting hopper 3/17/00 KVJ 12 Problems with Hoppers Ratholing/Piping Funnel Flow Arching/Doming Insufficient Flow 3/17/00 KVJ 13 Insufficient Flow - Outlet size too small - Material not sufficiently permeable to permit dilation in conical section -> “plop-plop” flow Material under compression in the cylinder section Material needs to dilate here 3/17/00 KVJ 14 Problems with Hoppers Ratholing/Piping Funnel Flow Arching/Doming Insufficient Flow Flushing 3/17/00 KVJ 15 Flushing Uncontrolled flow from a hopper due to powder being in an aerated state - occurs only in fine powders (rough rule of thumb - Geldart group A and smaller) - causes --> improper use of aeration devices, collapse of a rathole 3/17/00 KVJ 16 Problems with Hoppers Ratholing/Piping Funnel Flow Arching/Doming Insufficient Flow Flushing Inadequate Emptying 3/17/00 KVJ 17 Inadequate emptying Usually occurs in funnel flow silos where the cone angle is insufficient to allow self draining of the bulk solid. Remaining bulk solid 3/17/00 KVJ 18 Problems with Hoppers Ratholing/Piping Funnel Flow Arching/Doming Insufficient Flow Flushing Inadequate Emptying Mechanical Arching 3/17/00 KVJ 19 Mechanical Arching Akin to a “traffic jam” at the outlet of bin - too many large particle competing for the small outlet 6 x dp,large is the minimum outlet size to prevent mechanical arching, 8-12 x is preferred 3/17/00 KVJ 20 Problems with Hoppers Ratholing/Piping Funnel Flow Arching/Doming Insufficient Flow Flushing Inadequate Emptying Mechanical Arching KVJ- Caking 3/17/00 Time Consolidation 21 Time Consolidation - Caking Many powders will tend to cake as a function of time, humidity, pressure, temperature Particularly a problem for funnel flow silos which are infrequently emptied completely 3/17/00 KVJ 22 Segregation Mechanisms - Momentum or velocity - Fluidization - Trajectory - Air current - Fines 3/17/00 KVJ 23 What the chances for mass flow? Cone Angle Cumulative % of from horizontal hoppers with mass flow 45 0 60 25 70 50 75 70 *data from Ter Borg at Bayer 3/17/00 KVJ 24 Mass Flow (+/-) + flow is more consistent + reduces effects of radial segregation + stress field is more predictable + full bin capacity is utilized + first in/first out - wall wear is higher (esp. for abrasives) - higher stresses on walls - more height is required 3/17/00 KVJ 25 Funnel flow (+/-) + less height required - ratholing - a problem for segregating solids - first in/last out - time consolidation effects can be severe - silo collapse - flooding - reduction of effective storage capacity 3/17/00 KVJ 26 How is a hopper designed? Measure - powder cohesion/interparticle friction - wall friction - compressibility/permeability Calculate - outlet size - hopper angle for mass flow - discharge rates 3/17/00 KVJ 27 What about angle of repose? Pile of bulk solids 3/17/00 KVJ 28 Angle of Repose Angle of repose is not an adequate indicator of bin design parameters “… In fact, it (the angle of repose) is only useful in the determination of the contour of a pile, and its popularity among engineers and investigators is due not to its usefulness but to the ease with which it is measured.” - Andrew W. Jenike Do not use angle of repose to design the angle on a hopper! 3/17/00 KVJ 29 Bulk Solids Testing Wall Friction Testing Powder Shear Testing - measures both powder internal friction and cohesion Compressibility Permeability 3/17/00 KVJ 30 Sources of Cohesion (Binding Mechanisms) Solids Bridges -Mineral bridges -Chemical reaction -Partial melting -Binder hardening -Crystallization -Sublimation Interlocking forces 3/17/00 KVJ Attraction Forces -van der Waal’s -Electrostatics -Magnetic Interfacial forces -Liquid bridges -Capillary forces 31 Testing Considerations Must consider the following variables - time - temperature - humidity - other process conditions 3/17/00 KVJ 32 Wall Friction Testing Wall friction test is simply Physics 101 - difference for bulk solids is that the friction coefficient, , is not constant. P 101 F = N N F 3/17/00 KVJ 33 Wall Friction Testing Jenike Shear Tester WxA Bracket Cover Ring SxA Bulk Solid Wall Test Sample 3/17/00 KVJ 34 Wall shear stress, Wall Friction Testing Results Wall Yield Locus (WYL), variable wall friction Wall Yield Locus, constant wall friction ’ Normal stress, Powder Technologists usually express as the “angle of wall friction”, ’ ’ = arctan 3/17/00 KVJ 35 Jenike Shear Tester WxA Bracket Cover Ring SxA BulkSolid Solid Bulk Shear plane 3/17/00 KVJ 36 Other Shear Testers Peschl shear tester Biaxial shear tester Uniaxial compaction cell Annular (ring) shear testers 3/17/00 KVJ 37 Ring Shear Testers Arm connected to load cells, S x A Bulk solid WxA 3/17/00 KVJ Bottom cell rotates slowly 38 Shear test data analysis C 1 fc 3/17/00 KVJ 39 Stresses in Hoppers/Silos Cylindrical section - Janssen equation Conical section - radial stress field Stresses = Pressures 3/17/00 KVJ 40 Stresses in a cylinder Consider the equilibrium of forces on a differential element, dh, in a straightsided silo Pv A D dh h Pv A = vertical pressure acting from above A g dh = weight of material in element dh (Pv + dPv) A A g dh D (Pv + dPv) A = support of material from below D dh = support from solid friction on the wall (Pv + dPv) A + D dh = Pv A + A g dh 3/17/00 KVJ 41 Stresses in a cylinder (cont’d) Two key substitutions = Pw (friction equation) Janssen’s key assumption: Pw = K Pv This is not strictly true but is good enough from an engineering view. Substituting and rearranging, A dPv = A g dh - K Pv D dh Substituting A = (/4) D2 and integrating between h=0, Pv = 0 and h=H and Pv = Pv Pv = ( g D/ 4 K) (1 - exp(-4H K/D)) This is the Janssen equation. 3/17/00 KVJ 42 Stresses in a cylinder (cont’d) hydrostatic Bulk solids Notice that the asymptotic pressure depends only on D, not on H, hence this is why silos are tall and skinny, rather than short and squat. 3/17/00 KVJ 43 Stresses - Converging Section Over 40 years ago, the pioneer in bulk solids flow, Andrew W. Jenike, postulated that the magnitude of the stress in the converging section of a hopper was proportional to the distance of the element from the hopper apex. = ( r, ) This is the radial stress field assumption. 3/17/00 KVJ 44 Silo Stresses - Overall hydrostatic Bulk solid 3/17/00 Notice that there is essentially no stress at the outlet. This is good for discharge devices! KVJ 45 Janssen Equation - Example A large welded steel silo 12 ft in diameter and 60 feet high is to be built. The silo has a central discharge on a flat bottom. Estimate the pressure of the wall at the bottom of the silo if the silo is filled with a) plastic pellets, and b) water. The plastic pellets have the following characteristics: = 35 lb/cu ft ’ = 20º The Janssen equation is Pv = ( g D/ 4 K) (1 - exp(-4H K/D)) In this case: D = 12 ft = tan ’ = tan 20º = 0.364 H = 60 ft g = 32.2 ft/sec2 = 35 lb/cu ft 3/17/00 KVJ 46 Janssen Equation - Example K, the Janssen coefficient, is assumed to be 0.4. It can vary according to the material but it is not often measured. Substituting we get Pv = 21,958 lbm/ft - sec2. If we divide by gc, we get Pv = 681.9 lbf/ft2 or 681.9 psf Remember that Pw = K Pv,, so Pw = 272.8 psf. For water, P = g H and this results in P = 3744 psf, a factor of 14 greater! 3/17/00 KVJ 47 Types of Bins Pyramidal Conical Watch for inflowing valleys in these bins! 3/17/00 KVJ 48 Chisel Types of Bins Wedge/Plane Flow L B 3/17/00 L>3B KVJ 49 A thought experiment c 1 3/17/00 KVJ 50 c The Flow Function Time flow function Flow function 1 3/17/00 KVJ 51 c Determination of Outlet Size Time flow function c,t Flow function c,i 1 Flow factor 3/17/00 KVJ 52 Determination of Outlet Size B = c,i H()/ H() is a constant which is a function of hopper angle 3/17/00 KVJ 53 H() Function H() 3 2 1 10 20 30 40 50 60 Cone angle from vertical 3/17/00 KVJ 54 Example: Calculation of a Hopper Geometry for Mass Flow An organic solid powder has a bulk density of 22 lb/cu ft. Jenike shear testing has determined the following characteristics given below. The hopper to be designed is conical. Wall friction angle (against SS plate) = ’ = 25º Bulk density = = 22 lb/cu ft Angle of internal friction = = 50º Flow function c = 0.3 1 + 4.3 Using the design chart for conical hoppers, at ’ = 25º c = 17º with 3º safety factor & ff = 1.27 3/17/00 KVJ 55 Example: Calculation of a Hopper Geometry for Mass Flow ff = /a or a = (1/ff) a > c Condition for no arching => (1/ff) = 0.3 1 + 4.3 (1/1.27) = 0.3 1 + 4.3 1 = 8.82 c = 8.82/1.27 = 6.95 B = 2.2 x 6.95/22 = 0.69 ft = 8.33 in 3/17/00 KVJ 56 Material considerations for hopper design Amount of moisture in product? Is the material typical of what is expected? Is it sticky or tacky? Is there chemical reaction? Does the material sublime? Does heat affect the material? 3/17/00 KVJ 57 Material considerations for hopper design Is it a fine powder (< 200 microns)? Is the material abrasive? Is the material elastic? Does the material deform under pressure? 3/17/00 KVJ 58 Process Questions How much is to be stored? For how long? Materials of construction Is batch integrity important? Is segregation important? What type of discharger will be used? How much room is there for the hopper? 3/17/00 KVJ 59 Discharge Rates Numerous methods to predict discharge rates from silos or hopper For coarse particles (>500 microns) Beverloo equation - funnel flow Johanson equation - mass flow For fine particles - one must consider influence of air upon discharge rate 3/17/00 KVJ 60 Beverloo equation W = 0.58 b g0.5 (B - kdp)2.5 where W is the discharge rate (kg/sec) b is the bulk density (kg/m3) g is the gravitational constant B is the outlet size (m) k is a constant (typically 1.4) dp is the particle size (m) Note: Units must be SI 3/17/00 KVJ 61 Johanson Equation Equation is derived from fundamental principles - not empirical W = b (/4) B2 (gB/4 tan c)0.5 where c is the angle of hopper from vertical This equation applies to circular outlets Units can be any dimensionally consistent set Note that both Beverloo and Johanson show that W B2.5! 3/17/00 KVJ 62 Discharge Rate - Example An engineer wants to know how fast a compartment on a railcar will fill with polyethylene pellets if the hopper is designed with a 6” Sch. 10 outlet. The car has 4 compartments and can carry 180000 lbs. The bulk solid is being discharged from mass flow silo and has a 65° angle from horizontal. Polyethylene has a bulk density of 35 lb/cu ft. 3/17/00 KVJ 63 Discharge Rate Example One compartment = 180000/4 = 45000 lbs. Since silo is mass flow, use Johanson equation. 6” Sch. 10 pipe is 6.36” in diameter = B W = (35 lb/ft3)(/4)(6.36/12)2 (32.2x(6.36/12)/4 tan 25)0.5 W= 23.35 lb/sec Time required is 45000/23.35 = 1926 secs or ~32 min. In practice, this is too long - 8” or 10 “ would be a better choice. 3/17/00 KVJ 64 The Case of Limiting Flow Rates When bulk solids (even those with little cohesion) are discharged from a hopper, the solids must dilate in the conical section of the hopper. This dilation forces air to flow from the outlet against the flow of bulk solids and in the case of fine materials either slows the flow or impedes it altogether. 3/17/00 KVJ 65 Limiting Flow Rates Interstitial gas pressure Bulk density 3/17/00 Note that gas pressure is less than ambient pressure KVJ Vertical stress 66 Limiting Flow Rates The rigorous calculation of limiting flow rates requires simultaneous solution of gas pressure and solids stresses subject to changing bulk density and permeability. Fortunately, in many cases the rate will be limited by some type of discharge device such as a rotary valve or screw feeder. 3/17/00 KVJ 67 Limiting Flow Rates - Carleton Equation 4v sin 15 B sd 1/ 3 f 2 0 3/17/00 KVJ 2/3 4/3 f 0 5/ 3 p v g 68 Carleton Equation (cont’d) where v0 is the velocity of the bulk solid is the hopper half angle s is the absolute particle density f is the density of the gas f is the viscosity of the gas 3/17/00 KVJ 69 Silo Discharging Devices Slide valve/Slide gate Rotary valve Vibrating Bin Bottoms Vibrating Grates others 3/17/00 KVJ 70 Rotary Valves Quite commonly used to discharge materials from bins. 3/17/00 KVJ 71 Screw Feeders Dead Region Better Solution 3/17/00 KVJ 72 Discharge Aids Air cannons Pneumatic Hammers Vibrators These devices should not be used in place of a properly designed hopper! They can be used to break up the effects of time consolidation. 3/17/00 KVJ 73