Chapter3_8FlowOfGranular_3

Flow Behavior of Granular

Materials and Powders

Part III

Asst. Prof. Dr. Muanmai Apintanapong

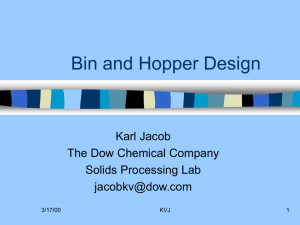

Bin and Hopper Design

Figure 1: a. pressure in a silo filled with a fluid (imaginary); b. vertical stress after filling the silo with a bulk solid; c. vertical stress after the discharge of some bulk solid

Gravity flow through orifices

Law of hydrodynamics do not apply to the flow of solid granular materials through orifices:

Pressure is not distributed equally in all directions due to the development of arches and to frictional forces between the granules.

The rate of flow is not proportional to the head, except at heads smaller than the container diameter.

No provision is made in hydrodynamics for size and shape of particles, which greatly influence the flow rate.

Particle history

Hopper Flow Modes

Mass Flow - all the material in the hopper is in motion, but not necessarily at the same velocity

Funnel Flow - centrally moving core, dead or non-moving annular region

Expanded Flow - mass flow cone with funnel flow above it

Mass Flow

all the material in the hopper is in motion at discharge, but not necessarily at the same velocity

Material in motion along the walls

D

Does not imply plug flow with equal velocity

Typically need 0.75 D to 1D to enforce mass flow

Funnel Flow

If a hopper wall is too flat and/or too rough, funnel flow will appear.

(centrally moving core, dead or nonmoving annular region)

“Dead” or nonflowing region or stagnant zone

Expanded Flow

mass flow cone with funnel flow above it

Mass Flow bottom section

Funnel Flow upper section

Problems with Hoppers

Ratholing/Piping and Funnel Flow

Arching/Doming

Insufficient Flow

Irregular flow

Inadequate Emptying

Time Consolidation - Caking

Ratholing/Piping

• Occurs in case of funnel flow.

• The reason for this is the strength

(unconfined yield strength) of the bulk solid.

• If the bulk solid consolidates increasingly with increasing period of storage at rest, the risk of ratholing increases.

Stable

Annular

Region

Funnel Flow

-Segregation

-Inadequate Emptying

-Structural Issues

Segregation

In case of centric filling, the larger particles accumulate close to the silo walls, while the smaller particles collect in the centre.

In case of funnel flow, the finer particles, which are placed close to the centre, are discharged first while the coarser particles are discharged at the end. If such a silo is used, for example, as a buffer for a packing machine, this behaviour will yield to different particle size distributions in each packing.

In case of a mass flow, the bulk solid will segregate at filling in the same manner, but it will become

"remixed" when flowing downwards in the hopper.

Therewith, at mass flow the segregation effect described above is reduced significantly.

Arching/Doming

• If a stable arch is formed above the outlet so that the flow of the bulk solid is stopped, then this situation is called arching.

• In case of fine grained, cohesive bulk solid, the reason of arching is the strength

(unconfined yield strength) of the bulk solid which is caused by the adhesion forces acting between the particles.

• In case of coarse grained bulk solid, arching is caused by blocking of single particles.

• Arching can be prevented by sufficiently large outlets.

Cohesive Arch preventing material from exiting hopper

Insufficient Flow

- Outlet size too small

- Material not sufficiently permeable to permit dilation in conical section > “plop-plop” flow

Material under compression in the cylinder section

Material needs to dilate here

Irregular flow

Irregular flow occurs if arches and ratholes are formed and collapse alternately. Thereby fine grained bulk solids can become fluidized when falling downwards to the outlet opening, so that they flow out of the silo like a fluid.

This behaviour is called flooding . Flooding can cause a lot of dust, a continuous discharge becomes impossible.

Inadequate emptying

Usually occurs in funnel flow silos where the cone angle is insufficient to allow self draining of the bulk solid.

Remaining bulk solid

Time Consolidation - Caking

Many powders will tend to cake as a function of time, humidity, pressure, temperature

Particularly a problem for funnel flow silos which are infrequently emptied completely

What the chances for mass flow?

Cone Angle Cumulative % of from horizontal hoppers with mass flow

45

60

0

25

70

75

*data from Ter Borg at Bayer

50

70

Mass Flow (+/-)

+ flow is more consistent

+ reduces effects of radial segregation

+ stress field is more predictable

+ full bin capacity is utilized

+ first in/first out

- wall wear is higher (esp. for abrasives)

- higher stresses on walls

- more height is required

Funnel flow (+/-)

+ less height required

- ratholing

- a problem for segregating solids

- first in/last out

- time consolidation effects can be severe

- silo collapse

- flooding

- reduction of effective storage capacity

How is a hopper designed?

Measure

- powder cohesion/interparticle friction

- wall friction

- compressibility/permeability

Calculate

- outlet size

- hopper angle for mass flow

- discharge rates

Types of Bins

Conical Pyramidal

Watch for inflowing valleys in these bins!

Types of Bins

Wedge/Plane Flow

B

L

L>3B

Chisel

Design diagram for mass flow (wedgeshaped hopper)

w

(angle of wall friction)

= effective angle of internal friction

(slope of hopper wall)

Design diagram for mass flow (conical hopper)

w

(angle of wall friction)

= effective angle of internal friction

(slope of hopper wall)

Stress conditions in the hopper

(emptying)

c

<

1

: flow

c

>

1

: arching is stable, no flow

1

= bearing stress,

1

= major principal stress

c

= unconfined yield strength

Flow function and time flow function

Hopper forms

Summary

The design of silos in order to obtain reliable flow is possible on the basis of measured material properties and calculation methods. Because badly designed silos can yield operational problems and a decrease of the product quality , the geometry of silos should be determined always on the basis of the material properties. The expenses for testing and silo design are small compared to the costs of loss of production, quality problems and retrofits.

Critical dimensions of hopper openings

To determine critical dimension, failure conditions must be established for two basic obstructions; arching (no flow) and piping (flow may be reduced or limited).

Consider that the strongest possible arch may form, the critical opening dimension (B) becomes:

B

c

/w (for slot opening)

B

2

c

/w (for circular opening)

Where w = bulk density

1

T = thickness

B = opening dimension

Flow factor (ff) depends upon:

effective angle of internal friction)

w

(angle of wall friction)

(slope of hopper wall)

w funnel flow

Mass flow ff

Example

Calculate the critical width B for arching of the slot opening of a wedge shaped, mild steel hopper with

= 30

C

55

For mild steel hopper with wall friction angle = 35

, the maximaum effective angle of friction (

) =

55

ff = 1.25

ff = 1.25

No intersection of ff and this

FF, there is no arching problem

ff = 1.25

c

= 50

There is an intersection of ff and this

FF, there is arching problem

1

= 65

From

1

= 65 lb/ft 2 ,

c

= 50 lb/ft 2 , w = 90 lb/ft 3 and

= 55

, therefore B

50/90

0.6 ft or critical slot with for arching is about 7 inches.

Determination of Outlet Size

B =

c,i

H(

)/W

H(

) is a constant which is a function of hopper angle

Bulk density = W

H(

) Function

3

2

1

10 20 30 40 50

Cone angle from vertical

60

Example: Calculation of a Hopper Geometry for

Mass Flow

An organic solid powder has a bulk density of 22 lb/cu ft. Jenike shear testing has determined the following characteristics given below. The hopper to be designed is conical.

Wall friction angle (against SS plate) =

w

= 25º

Bulk density = W = 22 lb/cu ft

Angle of internal friction =

= 50º

Flow function

c

= 0.3

1

+ 4.3

Using the design chart for conical hoppers, at

w

c = 17º with 3º safety factor

= 25º

& ff = 1.27

Example: Calculation of a Hopper Geometry for

Mass Flow ff =

/

a or

a

= (1/ff)

Condition for no arching =>

a

>

c

(1/ff)

= 0.3

1

+ 4.3 (1/1.27)

= 0.3

1

+ 4.3

1

= 8.82

c

= 8.82/1.27 = 6.95

B = 2.2 x 6.95/22 = 0.69 ft = 8.33 in

Discharge Rates (Q)

Numerous methods to predict discharge rates from silos or hopper

For coarse particles (>500 microns)

Beverloo equation - funnel flow

Johanson equation - mass flow

For fine particles - one must consider influence of air upon discharge rate

Beverloo equation

Q = 0.58

b g 0.5

(B - kd p

) 2.5

where Q is the discharge rate (kg/sec)

b is the bulk density (kg/m 3 ) g is the gravitational constant

B is the outlet size (m) k is a constant (typically 1.4) d p is the particle size (m)

Note: Units must be SI

Johanson Equation

Equation is derived from fundamental principles - not empirical

Q = b

(

/4) B 2 (gB/4 tan

c

) 0.5

where

c is the angle of hopper from vertical

This equation applies to circular outlets

Units can be any dimensionally consistent set

Note that both Beverloo and Johanson show that Q

B 2.5

!

Silo Discharging Devices

Slide valve/Slide gate

Rotary valve

Vibrating Bin Bottoms

Vibrating Grates

others

Rotary Valves

Quite commonly used to discharge materials from bins.

Screw Feeders

Dead Region

Better Solution

Discharge Aids

Air cannons

Pneumatic Hammers

Vibrators

These devices should not be used in place of a properly designed hopper!

They can be used to break up the effects of time consolidation.

Flow rate equations

From Ewalt and Buelow (1963), measuring flow of shell corn from straight-sided wooden bins equipped with test orifices:

Horizontal openings, circular orifice (8.4% MC db)

Q = 0.1196 B 3.1

Horizontal openings, rectangular orifice (12.1% MC db)

Q = 0.153 W 1.62

L 1.4

Vertical openings, circular orifice (12.7% MC db)

Q = 0.0351 B 3.3

Vertical openings, rectangular orifice (12.4% MC db)

Q = 0.0573 W 1.75

L 1.5

Q = KW n

K and n are two constants which can be found either by substituting experimental data from two sets of tests and solving the two equations simultaneously or by determination them directly from the slope and yintercepts of the straight line plot of Q versus one of the dimensions on log-log graph paper.

Q = f(

i

,

r

, d/D, D, bulk density and etc.)

There is no single parameter satisfactory relationship for estimating Q.

Most important parameter is the opening diameter (greatly affect on flow rate)

Q

D 3

Log Q

Slope ~ 2.8-3.2

Log D