USA Harness, Inc.

advertisement

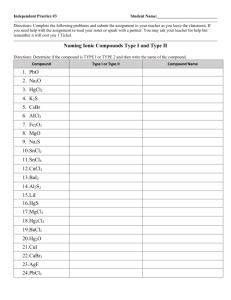

USA Harness, Inc. USA-Plus™ Wiring Harness System USA Harness, Inc. • Introduction • History and Capabilities • Organization Participation • Materials Specifications • Manufacturing/Quality Procedures • USA-Plus™ System/Warranty Terms • Independent Testing • Closing History and Capabilities • Began 1991 • 80,000 sf manufacturing & warehouse space at two facilities • 110 employees • In-house tool and die-making shop • Custom-designed products built to order • Trailer harnessing – light to heavy duty • Loom harnessing – multi-circuit applications; engine and transmission • Electronic security controls Organization Participation • TTMA – Truck Trailer Manufacturers Association • SAE – Society of Automotive Engineers • WHMA – Wiring Harness Manufacturers Association • NATM – National Association Trailer Manufacturers • IACOA – Independent Armored Car Operators Association • TMC – Technology & Maintenance Council (ATA) Materials Specifications • PVC Jacketed Cable - 19 strand AWG automotive copper Conforms to SAE and TTMA requirements -40° to +160°F working temperature range Resists oils, acids, alkalis, sunlight, heat, weathering, abrasion Custom-manufactured to USAH specifications • Terminations - Non-insulated brass, tin-coated stamped and formed contacts • Molding Compound - Virgin PVC compounds in 60, 75, 90 and 100 durometer hardness • Connectors - Metal or nylon sockets/plugs conforming to SAE J560 • Dielectric Grease - Corrosion preventative compound for electrical contacts installed in all female contacts Manufacturing Procedures • Termination - Calibrated machine press crimped terminations - Mandatory pull tests conducted to ensure correct crimp • Splicing - Ultrasonic welded splices for superior conductivity and reliability - All splices are tape wrapped to prevent short circuiting • Molding - Pressure injection molded into tool steel die sets - Cable jackets prepped with solvent for adhesion to mold compound • Inspection/Testing - All parts visually and mechanically inspected to custom print - All parts tested electronically to ensure conductivity and loading USA-Plus™ System • Patented Connector Design (2001) • 10-Circuit Capability • Keyed Termination Orientation • Integral Interior O-Ring Primary Seal • Secondary Pin Lock • Virgin Vinyl Mold Compound • 5-Year Material/Workmanship Warranty Independent Testing • ASTM B117 Salt Spray Test (American Society for Testing & Materials) • Grote & Truck-Lite LED Lamps • Successfully Completed 500 hours of Continuous Operation • SAE J560 for Sockets & Plugs Requires 168 hours – USA-Plus™ nearly 3X!! USA-Plus™ Premium Harness System • Seeking ISO 9001:2000 certification • Leading the way in HD trailer industry for custom harnessing • Thank You for viewing this presentation!! • Any Questions?? See Contact Us page.