Functional Polymers From Renewable Resources

advertisement

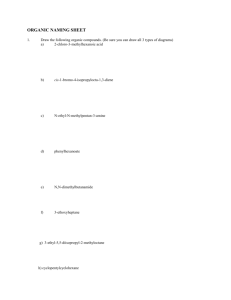

Functional Polymers From Renewable Resources S. Shang, A. Ro, S. J. Huang and R. A. Weiss Polymer Program University of Connecticut Storrs, CT New England Green Chemistry Consortium Annual Meeting University of Maine Orno, ME May 31, 2006 Polymers based on renewable resources crops, grasses, agricultural byproducts Raw materials are sustainable; Polymers can be designed to be biodegradable O O Monomers From Renewable Resources Lactic Acid O CH3 HO Itaconic Anhydride OH Stearyl Methacrylate O O O Fermentation of agricultural by-products (carbohydrates), e.g., corn starch Pyrolysis of citric acid, or Fermentation of carbohydrates to form itaconic acid, followed by dehydration Derived from fatty acid from animal or vegetable fats or oils Poly(lactic acid), PLA CH3 CH3 Azeotropic Distillation - H2O OH * * O HO O O High Molecular Weight PLA n Ring Opening Polymerization (SnOct2 with coinitiator) Condensation -H2O O Depolymerization SnOct2 CH3 H H3C O OH O O O Prepolymer Mn ~ 5000 CH3 n O Lactide Drumwright, R. E.; Gruber, P. R.; Henton, D. E. Adv. Mater. 2000. 12. 1841. Applications: Fibers, films, moldable thermoplastics (Tm ~ 175C), sutures Deficiencies: Low Tg (~ 60C), Narrow melt processing window, Brittle plastic, hydrophobic; incompatible with other polymers (blends) Ionomers Predominantly hydrophobic polymers that contain modest amounts of bonded acid or salt groups (~ 15 mol%) Interchain association of salt groups significantly alters thermal properties, mechanical properties and rheology. PS 1.82 NaSPS 3.44 NaSPS 5.81 NaSPS Applications: coatings, fibers, thermoplastics, adhesion promoters, compatibilizers, viscosifiers, permselective membranes, hydrogels… Research Goals Synthesize and Characterize Ionomers Derived from Lactic Acid, Itaconic Anhydride and Stearyl Methacrylate CH3 H2 C O Random Ionomer -+ n C C H2 O O O O ITA O CH m C O H2C ITA C H2 O CH2 O -+ C C n m O O CH3 H2 C CH3 H2C O x H a Telechelic Ionomer CH3 O O O O O O Telechelic PLA A O H + -+ O n -+ itaconic ahydride ethyl acetate, O 120oC, SnOct2 PLA b SM O O O O O telechelic PLA B PLA OH n O ITA O -+ Radical copolymerizaton of ITA and SM AIBN, 80oC + O O O O O 5 O No peak Absorption O O Ethyl Acetae 1782 co(ITA/SM) CH2 C n CH2 O 1.5 Copolymer 1731 O 2.0 O 1862 m O 1730 O (CH2)17CH3 O SM (CH2)17CH3 4 O O (CH2)17CH3 AIBN, 80o C O+ O (CH2)17CH3 3 Mixture 1.0 Copolymer ITA 0.0 1800 2500 Ethyl Acetae (CH2)17CH3 Mixture SM 3000 O O 0.5 1 AIBN, 80o C O+ 1720 O O 2 0 m O Ethyl Acetate O ITA 6 n 2000 1500 1780 1760 1740 1720 1700 1000 1680 1660 1601 Wavelength (cm-1) IR evidence for copolymerizaiton: 1862, 1782 cm-1: ITA (anhydride) 5 member ring shift of C=O in SM from 1720 to 1731 cm-1 indicating reaction of C=C disappearance of peak at 1601 cm-1: reaction of C=C CH2 O Copolymerization of ITA and SM 1.0 0.8 FITA rITA = r1 = 0.53 r1 f12 f1 f 2 F1 r1 f12 2 f1 f 2 r2 f 22 rSM = r2 = 0.12 0.6 Random Copolymers 0.4 0.2 0.0 0.0 J. Wallach, PhD Dissertation, Univ. Conn., 2000 0.2 0.4 0.6 0.8 1.0 fITA Mn (25k – 60kDa) decreased with increasing fITA Thermal behavior of ITA-co-SM copolymers DSC: 1st scan after ppt from soln. 10 Increasing SM composition g Heat Flow (W/g) f 0 e d c b -10 a -20 -40 -20 0 20 40 60 80 100 fITA Mn (kDa) Tm (C) DH (J/g SM) 0 57.1 30.2 62.8 0.29 45.1 31.2 83.0 0.40 33.0 32.1 77.0 0.53 34.8 44.7 87.9 0.54 29.1 48.2 50.9 0.45 24.1 45.6 21.3 120 o Temperature ( C) Crystallinity is due to the SM side chain packing Melting temperature increased with increasing ITA content! Effect of ITA on crystallinity was complicated. No glass transition was observed (Tg(ITA) ~ 130C). Crystalline structure of ITA-co-SM SAXS (100 % ITA) Intensity (45) (53.8) (52.8) (29.0) (0) 0.5 1.0 1.5 2.0 2.5 3.0 d (nm) 0 2.95 29.0 2.96 45 52.8 3.98 3.18 53.8 3.55 100 -- Length of alkyl side chain = 2.5 nm q (nm-1) WAXD Composition (mol% ITA) (58% ITA) Intensity (45) (53) 0.417 nm characteristic of n-alkyl hexagonal packing, (45) (29) Poly(SM) 10 12 14 16 q (nm-1) 18 20 Side-Chain, Stearyl Methacrylate Crystals L L L Intercalated Crystal Bilayer Crystal 3.9 nm 27 Zn-Stearate Bilayer Crystal ITA-co-SM Ionomers (Mn=33 kDa; 40 mol% ITA) 1630 1570 2+ Ca Salt (50%) 1570 Na+ Salt (100%) ITA-co-SM (40% ITA) 2000 1900 1800 1700 1600 1500 Wavenumber (cm-1) IR evidence of neutralization Peak ~ 1550-1650 cm-1 due to COO- 1400 Ionomer Structure and Properties TMA (F = 60 mN) SAXS 1.0 Ca-salt (50%) ITA-co-SM (40% ITA) Probe Height Intensity Na-salt (100%) Poly(SM) 0.0 0.5 1.0 1.5 2.0 2.5 3.0 Na-Salt (100%) 0.8 ITA-co-SM (40% ITA) 0.6 0.4 Ca-Salt (50%) 0.2 0.0 3.5 q (nm-1) 0 20 40 60 o Temperature ( C) Ionic aggregation was observed Long spacing of SM crystals increased upon neutralization Neutralization increased the elasticity of the polymer. 80 Chemical Recycling of PLA by Transesterification Transesterification Uncatalyzed - slow process, reaction temperature 250-300C. Catalyzed - lower time and temperature (J. Wallach, PhD Dissertation, Univ. Conn., 2000). – SnOct2. FDA approved. Mechanism R O CH3 O O H CH3 O O O OH O OH O O O Sn Oct2 H O O R SnOct2 CH3 O OH + R O O OH O O SnOct2 Synthesis of ω-carboxylate functionalized PLA A. Synthesis of methacrylate-terminated PLA O O OH + O O CH3 SnOct2 O HO O H n O n CH3 2-hydroxyethyl methacrylate H O O poly(lactic acid) telechelic PLA A B. Functionalization with itaconic anhydride O CH3 O O O Telechelic PLA A O O H + O O n itaconic ahydride ethyl acetate, O 120oC, SnOct2 O O O O O telechelic PLA B OH n O O O O O O O Broad OH stretch OH n C=O stretch O C-O-H in-plane bend and C-O stretch Carboxylic C=O stretch C=C stretch O O O O O O O n M O Asymmetric carboxylate anion stretch 1H-NMR Spectrum of Functionalized PLA Oligomer d End group Analysis Mn = 1930, with 25 LLA units c c d h h Glass Transition Temperatures of PLA-ITA Telechelic Ionomers Cations = Li+, Na+, K+, Ca2+, Zn2+, Y3+ 55 50 c = 0.6 mol% (M ~ 13,000 g/mole) o Tg ( C) 45 40 c = 2.1 mol% M ~ 3,000 g/mole 35 30 25 0.0 Ca K Na Li 0.2 0.4 0.6 0.8 1.0 1.2 Zn 1.4 Y 1.6 1.8 q/a For higher molecular weight (M ~ 15,000 – 900,000), Tg was relatively insensitive to functionalization Acknowledgments Funding by: New England Green Chemistry Consortium NSF/EPA Petroleum-Based Polymers * Hydrophobic and resistant to biodegradation Escalating prices of petroleum (only ~ 2% of petroleum is used for polymers) * Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures for 2003, U.S. Environmental Protection Agency, 2003. Tullo, Chem. Eng. News. 2005, 83, 19. Environmental Concerns Plastics production has nearly doubled every 10 years for four decades. Environmental Issue Plastic are the largest volume component in U.S. landfills (~ 25%) Sustainability Issue Existing petroleum resources are limited. Biodegradable Polymers Aliphatic Polyesters from Hydroxyacids Poly(3-hydroxybutyric acid) O CH3 O Poly(lactic acid) NatureWorks LLC CH3 O O n n Itaconic Anhydride • Ramos – PEG functionalization O O A RO OH ROH O O SnOct2 O RO B OH O O • Biocompatible – citric acid distillation, fermentation of carbohydrates (Aspergillus terreus) Ramos, M. Multi-component Hydrophilic-Hydrophobic Systems From Itaconic Anhydride. Ph.D. Thesis, University of Connecticut, Storrs, CT, 2002.