Products and Services

To Accompany Russell and Taylor, Operations Management, 4th Edition, 2003 Prentice-Hall, Inc. All rights reserved.

Design of Products

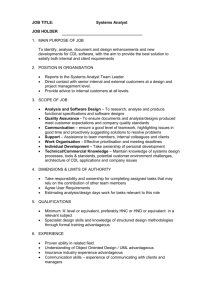

Humor in Product Design

As the customer wanted

it.

© 1984-1994 T/Maker Co.

As Operations made it.

© 1984-1994 T/Maker Co.

As Marketing

interpreted it.

© 1984-1994 T/Maker Co.

As Engineering

designed it.

© 1984-1994 T/Maker Co.

What is a Product?

• Need-satisfying offering of an organization

– Example

• P&G does not sell laundry detergent

• P&G sells the benefit of clean clothes

• Customers buy satisfaction, not parts

• May be a good or a service

Why Companies Design New Products

and Services

To be competitive

To increase business growth and profits

To avoid downsizing with development of new

products

To improve product quality

To achieve cost reductions in labor or materials

Product or Service Design Activities

• Translate customer wants and needs into product and service

requirements (marketing, operations)

• Refine existing products and services (marketing)

• Develop new products and services (marketing, operations)

• Formulate quality goals (marketing, operations)

• Formulate cost targets (accounting, finance, operations)

• Construct and test prototypes (operations, marketing,

engineering)

• Document specifications

• Translate product and service specifications into process

specifications (engineering, operations)

Reasons for Design or Re-Design

• The driving forces for product and service design or

redesign are market opportunities or threats:

– Economic

– Social and Demographic

– Political, Liability, or Legal

– Competitive

– Cost or Availability

– Technological

Major Factors to be Considered in the

(Product and Service) Design Strategy

•Function of product/service

•Cost

•Quality

•Time-to-market

•Appearance

•Customer satisfaction

•Ease of production/assembly

•Ease of maintenance/service

Product and service design – or redesign – should be

closely tied to an organization’s strategy

Product Design

Specifies materials

Determines dimensions &

tolerances

Defines appearance

Sets performance standards

Service Design

Specifies what the customer is to experience

Physical items

Sensual benefits

Psychological

benefits

An Effective Design Process

Matches product/service characteristics with

customer needs

Meets customer requirements in the

simplest, most cost-effective manner

Reduces time to market

Minimizes revisions

Few Successes

2000

1500

1000

500

0

Number of

Ideas

1750

Design review,

Testing, Introduction

Market

requirement

1000

Functional

specifications

500

Product

specification

100

Development Stage

25

One

success!

Key Questions (1 of 2)

• Is there a demand for it?

– Market size

– Demand profile

• Can we do it?

– Manufacturability - the capability of an organization

to produce an item at an acceptable profit

– Serviceability - the capability of an organization to

provide a service at an acceptable cost or profit

Key Questions (2 of 2)

• What level of quality is appropriate?

– Customer expectations

– Competitor quality

– Fit with the current offering

• Does it make sense from an economic standpoint?

– Liability issues, ethical considerations,

sustainability issues, costs and profits

Legal Considerations

• Legal Considerations

– Product liability

• The responsibility a manufacturer has for any

injuries or damages caused by as faulty product

• Some of the concomitant costs

– Litigation

– Legal and insurance costs

– Settlement costs

– Costly product recalls

– Reputation effects

Normative Behavior in Product Design

• Produce designs that are consistent with the goals of

the organization

– e.g., Do not compromise on quality, or cut corners,

even in areas that are not apparent to the customer

• Give customers the value they expect

• Make health and safety a concern

– Do not place employees, customers, or third parties

at risk because of faulty products and services

Sustainability

• Sustainability

– Using resources in ways that do not harm the

ecological systems that support human existence

• Key aspects of designing for sustainability

– Life cycle assessment

– Reduction of costs and materials used

– Re-using parts of returned products

– Recycling

Life Cycle Assessment (LCA)

• LCA

– The assessment of the environmental impact of a

product or service throughout its useful life

• Focuses on such factors as

– Global warming

– Smog formation

– Oxygen depletion

– Solid waste generation

• LCA procedures are part of the ISO 14000

environmental management procedures

Reduce: Costs and Materials

• Value Analysis/Value Engineering

– Examination of the function of parts and materials

in an effort to reduce the cost and/or improve the

performance of a product

– Achieve equivalent or better performance at a

lower cost while maintaining all functional

requirements defined by the customer

– Ratio of Value/Cost

– Value analysis focuses on design improvments

during production

Common Questions Used in Value Analysis/

Value Engineering

• Could a less expensive part of material be

used?

• Is the function necessary?

• Can the function of two or more parts be

performed by a single part?

• Can a part be simplified?

• Could product specifications be relaxed?

• Could standard parts be substituted for nonstandard parts?

Common Questions Used in Value Analysis/

Value Engineering

Assessment of value :

– Can we do without it?

– Does it do more than is required

– Does it cost more than it is worth?

– Can something else do a better job

– Can it be made by less costly method, tools, material?

– Can it be made cheaper, better or faster by someone

else?

– Does the item have any design features that are not

necessary?

– Can two or more parts be combined into one?

– Are there nonstandard parts that can be eliminated

Benefits of VA/VE

• Benefits:

simplified products

additional standardization of products

improved functional aspects of product

improved job design and job safety

improved maintainability of the product

robust design

reduction in cost

Cost Reduction of a Bracket via Value

Engineering

Re-Use: Remanufacturing

• Remanufacturing

– Refurbishing used products by replacing worn-out or

defective components (and reselling the products)

• Can be performed by the original manufacturer or

another company

– Design for disassembly (DFD)

• Designing products so that they can be easily taken

apart

• Includes fewer parts and less material and using

snap-fits where possible instead of screws or nuts

and bolts

Recycle

• Recycling

– Recovering materials for future use

• Applies to manufactured parts

• Also applies to materials used during

production

– Why recycle?

• Cost savings

• Environmental concerns

• Environmental regulations

– Design for recycling (DFR)

• Product design that takes into account the

ability to disassemble a used product to recover

the recyclable parts

Design for the Environment

Design safe and environmentally sound (eg.

recyclable) products

Design from recycled material

Use materials which can be recycled

Design for ease of repair

Minimize packaging

Minimize material & energy

used during manufacture, consumption &

disposal

“Green Manufacturing”

•

•

•

•

•

•

Make products recyclable

Use recycled materials

Use less harmful ingredients

Use lighter components

Use less energy

Use less material

Benefits of Environmentally Friendly

Designs

• Benefits

– Safe and environmentally sound products

– Minimum raw material and energy waste

– Product differentiation

– Environmental liability reduction

– Cost-effective compliance with environmental regulations

– Recognition as good corporate citizen

Design for the

Environment

Other Considerations in Product and

Service Design

•

•

•

•

Product or service life cycles

Standardization

Product or service reliability

Product or service robustness

Product or service life stages

Products in Various Stages of Life Cycle

Sales

Growth

Introduction

CD-ROM

Internet

Maturity

Decline

Jet Ski, fax machines

Boeing

727

3½

Floppy

disks

Flatscreen

monitors

Time

Standardization

Standardization

Extent to which there is absence of variety in a

product, service or process

Standardized products are immediately available to

customers

Advantages of Standardization

(1 of 2)

• Fewer parts to deal with in inventory & manufacturing

• Design costs are generally lower

• Reduced training costs and time

• More routine purchasing, handling, and inspection

procedures

Advantages of Standardization (2 of 2)

• Orders fillable from inventory

• Opportunities for long production runs and automation

• Need for fewer parts justifies increased expenditures on

perfecting designs and improving quality control

procedures.

Disadvantages of Standardization

• Designs may be frozen with too many imperfections

remaining.

• High cost of design changes increases resistance to

improvements.

• Decreased variety results in less consumer appeal.

Designing for Mass Customization

Mass customization: A strategy of producing basically

standardized goods or services, but incorporating

some degree of customization in the final product or

service

Facilitating Techniques

Delayed differentiation

Modular design

Delayed Differentiation

Delayed differentiation is the process of producing

but not quite completing a product or service until

customer preferences or specifications are known

It is a postponement tactic (produce a piece of

furniture, but do not stain it until the customer

chooses the stain)

Modular Design

Modular design is a form of standardization in which

component parts are subdivided into modules that are

easily replaced or interchanged.

Advantages

•

•

•

•

easier diagnosis and remedy of failures

easier repair and replacement

simplification of manufacturing and assembly

And it adds flexibility to both production and marketing

Disadvantages

• Limited number of possible product configurations

• Limited ability to repair a faulty module; the entire module must

be scrapped

Reliability

Reliability: The ability of a product, part or system to perform

its intended function under a prescribed set of conditions

over a specified length of time. It is expressed as the

probability that the product performs its intended function for

a specified length of time

Normal Operating Conditions: the set of conditions under

which an item’s reliability is specified

Maintainability: Ease and/or cost of maintaining/ repairing

product

Computing Reliability (1 of 2)

Components in series

0.90

0.90

0.90 x 0.90 = 0.81

Computing Reliability (2 of 2)

Components in series

0.90

0.90 x 0.90 = 0.81

0.90

Components in parallel

0.90

R2

0.95 + 0.90(1-0.95) = 0.995

0.95

R1

Robust Design

• Robust design

A design that results in products or services that can

function over a broad range of conditions

A robust product is to be designed that is insensitive to

environmental factors either in manufacturing or in use

Pertains to product as well as process design

Consider the following automobiles:

Ferrari 599

Toyota Avalon

Which is design is more robust?

Design for Robustness

Product can fail due to poor design quality

Products are subjected to many conditions

Product is designed so that small variations in

production or assembly do not adversely affect the

product

Design products for consistent performance

Robust design studies

• Controllable factors - under designer’s control

• Uncontrollable factors - from user or environment

Central feature is parameter design

Degree of Newness

• Product or service design changes can be in the form of:

– Modification of an existing product or service

– Expansion of an existing product line or service

offering

– Clone of a competitor’s product or service

– New product or service

• The degree of change affects the newness of the product

or service to the market and to the organization

– Risks and benefits?

50%

45%

40%

35%

30%

25%

20%

15%

10%

5%

0%

Industry Leader

Percent of Sales From New Product

Top

Third

Middle

Third

Bottom

Third

Position of Firm in Its Industry

Phases in Design & Development

1.

2.

3.

4.

5.

6.

7.

8.

9.

Idea generation

Feasibility analysis

Product specifications

Process specifications

Prototype development

Design review

Market test

Product introduction

Follow-up evaluation

Main Phases in the Design Process

1.

2.

3.

4.

5.

Idea Generation — Product Concept

Feasibility Study — Performance

Specifications

Preliminary Design — Prototype

Final Design — Final Design Specifications

Process Planning — Manufacturing

Specifications

The Design Process

Idea

generation

Suppliers

Product or

service concept

Feasibility

study

Performance

specifications

Form design

Customers

R&D

Marketing

Competitors

Revising and testing

prototypes

Production

design

Functional

design

New product or

service launch

Final design

& process plans

Design

specifications

Pilot run

and final tests

Manufacturing

or delivery

specifications

Step 1: Idea Generation (1 of 5)

Suppliers, distributors, salespersons, competitors

Trade journals and other published material

Warranty claims, customer

complaints, failures

Customer surveys, focus

groups, interviews

Field testing, trial users

Research and development

Idea Generation (2 of 5)

1. Supply-chain based

2. Competitor based

3. Research based

Supply-Chain Based (3 of 5)

• Ideas can come from anywhere in the supply chain:

– Customers

– Suppliers

– Distributors

– Employees

– Maintenance and repair personnel

Competitor-Based (4 of 5)

• By studying how a competitor operates and its

products and services, many useful ideas can be

generated

• Reverse engineering

– Dismantling and inspecting a competitor’s product to

discover product improvements

Research Based (5 of 5)

• Research and Development (R&D)

– Organized efforts to increase scientific knowledge or product

innovation & may involve:

– Basic research

• Has the objective of advancing the state of knowledge about a

subject without any near-term expectations of commercial

applications

– Applied research

• Has the objective of achieving commercial applications

– Development

• Converts the results of applied research into useful commercial

applications.

Tools of Idea Generation

Perceptual Maps

Visual comparison of

customer perceptions

Benchmarking

Comparing product/service

against best-in-class

Reverse engineering

Dismantling and inspecting a competitor’s product to

discover product improvements

Step 2: Feasibility Study

Market

Analysis

Economic

Analysis

Technical / Strategic Analysis

Performance Specifications are written for product

concepts that pass the feasibility study

Step 3: Preliminary Design

Create form & functional design

Build prototype

Test prototype

Revise prototype

Retest

3.1. Form Design

(How the Product Looks)

Cellular Personal Safety

Alarm

Personal Computer

3.2. Functional Design

Relates to how the product performs

Relates to the concept of Reliability and Maintainability

3.3. Production Design

Part of the preliminary design phase

Simplification

Standardization

Mass customization

3.3.1. Design Simplification (1 of 3)

(a) The original design

Assembly using

common fasteners

3.3.1. Design Simplification (2 of 3)

(a) The original design

Assembly using

common fasteners

(b) Revised design

One-piece base &

elimination of

fasteners

3.3.1. Design Simplification (3 of 3)

(a) The original design

Assembly using

common fasteners

(b) Revised design

(c) Final design

One-piece base &

elimination of

fasteners

Design for

push-and-snap

assembly

Steps 4&5: Final Design & Process Plans

Produce detailed drawings & specifications

Create workable instructions for manufacture

Select tooling & equipment

Prepare job descriptions

Determine operation & assembly order

Program automated machines

Product Strategy Options

Product differentiation

Low cost

Rapid response (product life cycles are becoming

shorter, therefore faster developers of new products

gain on slower developers and obtain a competitive

advantage)

Improving the Design Process

Design teams & concurrent design

Design for manufacturing - Manufacturability

Component commonality

Design for assembly

Design for disassembly

Design to prevent failures and ensure value

Design for the environment

Measure design quality

Utilize quality function deployment

Utilize Computer Aided Design

Design for robustness

Engage in collaborative design

Organizing for Product Development (1 of 2)

• Historically – distinct departments

– Duties and responsibilities are defined

– Difficult to foster forward thinking

• Today – team approach

– Representatives from all disciplines or functions

– Concurrent engineering – cross functional team

Organizing for Product Development (2 of 2)

• Traditional Approach

– “We design it, you build it” or “Over the wall”

• Concurrent Engineering

– “Let’s work together simultaneously”

“Over the Wall” Approach

New

Product

Mfg

Design

Breaking Down Barriers to Effective

Design

Design Teams

Marketing, manufacturing, engineering

purchasing personnel

Suppliers, dealers, customers

Lawyers, accountants, insurance

companies

Concurrent Engineering: Defined

Concurrent engineering is the bringing together of personnel

from various functions together early in the design phase.

CE can be defined as the simultaneous development of

project design functions, with open and interactive

communication existing among all team members for the

purposes of reducing time to market, decreasing cost, and

improving quality and reliability

Time savings are created by performing activities in parallel

DFM and DFA

• Design for manufacturing (DFM)

The designing of products that are compatible with

an organization’s abilities

• Design for assembly (DFA)

Design that focuses on:

reducing the number of parts in a

product

the assembly methods

the sequence of assembly operations

Design for Manufacturing and Assembly

Design a product for easy & economical production

Incorporate production design early in the

design phase

Taking into account the manufacturing capabilities (equipment, skills,

types of materials, schedules, technologies) of the organization in

designing goods

The more general term “design for operations” encompasses services

as well as manufacturing

Improves quality, productivity and reduces costs

Shortens time to design and manufacture

DFMA Guidelines

1. Simplify products by reducing the number of separate

parts

2. Minimize the number of parts, tools, fasteners, and

assemblies

3. Use standard parts and repeatable processes

4. Design parts for many uses

5. Incorporate modularity in design

6. Design for ease of assembly, minimal handling

7. Allow for efficient testing and parts replacement

Design for Manufacturing and Assembly

DFMA software allows designers to examine the integration of

part designs before the product is manufactured.

Answers are required for such questions as:

• During the operation of the product, does the part move

relative to all other parts already assembled?

• Must the part be of a different material or be isolated

from other parts already assembled?

• Must the part be separate from all other parts to allow the

disassembly of the product for adjustment or

maintenance?

Manufacturability

• Manufacturability

– Ease of fabrication and/or assembly

– It has important implications for

• Cost

• Productivity

• Quality

Component Commonality

• When products have a high degree of similarity in

features and components, a part can be used in

multiple products

• Benefits:

– Savings in design time

– Standard training for assembly and installation

– Opportunities to buy in bulk from suppliers

– Commonality of parts for repair

– Fewer inventory items must be handled

Design Review

Failure Mode and Effects Analysis (FMEA)

A systematic approach for analyzing causes &

effects of failures

Prioritizes failures

Attempts to eliminate causes

Fault Tree Analysis (FTA)

Study interrelationship between failures

Value Analysis (VA)

Fault Tree for Potato Chips

FMEA for Potato Chips

FAILURE

MODE

CAUSE OF FAILURE

EFFECT OF FAILURE

CORRECTIVE ACTION

Stale

Low moisture

content, expired shelf

life, poor packaging

Tastes bad, won’t

crunch, thrown out,

lost sales

Add m cure longer,

better package seal,

shorter shelf life

Broken

Too thin, too brittle,

rough handling,

rough use, poor

packaging

Can’t dip, poor

display, injures

mouth, chocking,

perceived as old, lost

sales

Change recipe,

change process,

change packaging

Too Salty

Outdated receipt,

process not in

control, uneven

distribution of salt

Eat less, drink more,

health hazard, lost

sales

Experiment with

recipe, experiment

with process,

introduce low salt

version

Designing for the Customer:

Quality Function Deployment (QFD)

QFD is an approach that integrates the “voice of the customer” into

the product and service development process. Translates customer

preferences into specific product characteristics

Enables to design for the customer

Cross functional teams are used

Displays requirements in matrix diagrams

First matrix called “house of quality”

Series of connected houses

Quality Function Deployment Process

Identify customer wants

Identify how the good/service will satisfy customer

wants

Relate customer wants to product hows

Identify relationships between the firm’s hows

Develop importance ratings

Evaluate competing products

Importance

House of Quality (1 of 2)

5

Correlation matrix

3

Design

requirements

1

4

2

Customer

requirements

Relationship

matrix

Competitive

assessment

6

Target values

House of Quality (2of 2)

Series of QFD Houses

Part

characteristics

Process

characteristics

A-2

Parts

deployment

Operations

A-3

Process

planning

Process

characteristics

House

of

quality

Part

characteristics

A-1

Product

characteristics

Customer

requirements

Product

characteristics

A-4

Operating

requirements

Benefits of QFD

Promotes better understanding of customer

demands

Promotes better understanding of design

interactions

Involves manufacturing in the

design process

Breaks down barriers between

functions and departments

Provides documentation of

the design process

Technology in Design: Computer

Aided Design (CAD)

• Product design using

computer graphics

• Designing products at

a computer terminal or

work station

– Design engineer

develops rough

sketch of product

– Uses computer to

draw product

• Often used with CAM

© 1995 Corel Corp.

Technology in Design

CAD - Computer Aided Design

Assists in creating and

modifying designs

CAE - Computer Aided Engineering

Tests & analyzes designs

on computer screen

CAM refers to the use of specialized

computer programs to direct and

control manufacturing equipment

CAD/CAM - Design & Manufacturing

Automatically converts CAD data into processing instructions

for computer controlled equipment

Benefits of CAD (1 of 2)

Produces better designs faster

Increases the productivity of designers, 3 to 10 times and thus

allows more time for designers to work on creative projects

Reduces costs and increases product quality

Creates a database for manufacturing information on product

specifications (Builds database of designs and creates

documentation to support them)

Shortens time to market

Benefits of CAD (1 of 2)

Reduces time to manufacture

Enlarges design possibilities

Enhances communication and promotes innovation in design

teams

Provides the possibility of engineering and cost analysis on

proposed designs

CAD that includes finite element analysis (FEA) can

significantly reduce time to market

Enables developers to perform simulations that aid in

the design, analysis, and commercialization of new

products

Consistency is Important in Design

Consistent errors are easier to correct than

random errors

Parts within tolerances

may yield assemblies

which aren’t

Consumers prefer

product characteristics

near their ideal values

Kano Model

• Basic quality

– Refers to customer requirements that have only limited

effect on customer satisfaction if present, but lead to

dissatisfaction if absent

• Performance quality

– Refers to customer requirements that generate

satisfaction or dissatisfaction in proportion to their level of

functionality and appeal

• Excitement quality

– Refers to a feature or attribute that was unexpected by the

customer and causes excitement

The Kano Model

Customer Satisfaction

Kano Model

Excitement

Expected

Must Have

Customer Needs

Trends in Product & Service Design (1 of 2)

Increased emphasis on or attention to:

Customer satisfaction (by translating customer wants and

needs into product and service requirements)

Reducing time to introduce new product or service

Reducing time to produce product

Trends in Product & Service Design (2 of 2)

Increased emphasis on or attention to:

The organization’s capabilities to produce or deliver the

item

Refining existing products and services

Environmental concerns

Designing products & services that are “user friendly”

Designing products that use less material

Global Product Design

Virtual teams

Uses combined efforts of a team of designers working

in different countries

Provides a range of comparative advantages over

traditional teams such as:

Engaging the best human resources around the

world

Possibly operating on a 24-hr basis

Global customer needs assessment

Global design can increase marketability

Design Guidelines (1 of 2)

Produce designs that are consistent with the goals of the

company

Take into account the operations capabilities of the

organization in order to achieve designs that fit with those

capabilities

Take into account the cultural differences related to

product design (for multinationals)

Give customers the value they expect

Make health and safety a primary concern

Consider potential harm to the environment

Design Quidelines (2 of 2)

•

•

•

•

•

•

Increased emphasis on components commonality

Package products and services

Use multiple-use platforms

Consider tactics for mass customization

Look for continual improvement

Shorten time to market