bobcat drillers - Texas State University

advertisement

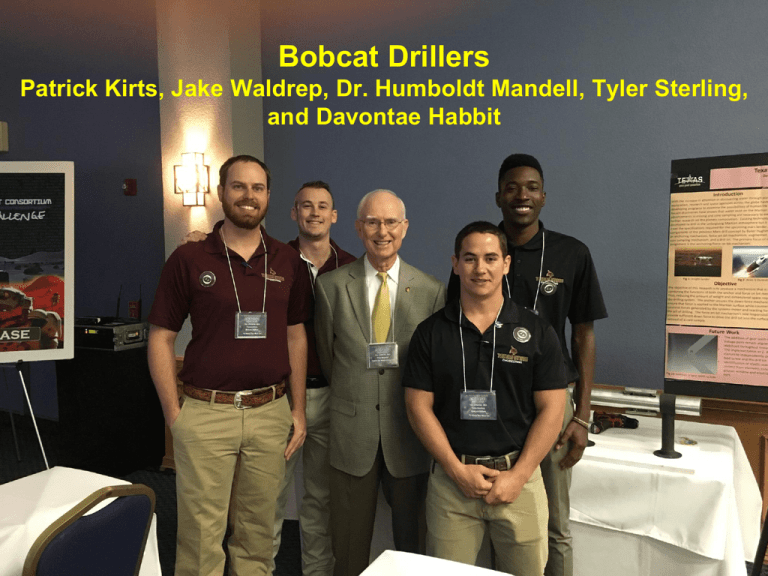

Bobcat Drillers Patrick Kirts, Jake Waldrep, Dr. Humboldt Mandell, Tyler Sterling, and Davontae Habbit BOBCAT DRILLERS Davontae Habbit, Patrick Kirts, Tyler Sterling, and Jake Waldrep BACKGROUND: Product: Mars Drill, designing of anchor mechanism to apply downforce • Sponsor: Texas Space Grant Consortium (TSGC), NASA Funding • • Contact: Dr. Humbolt Mandell, UTAustin • Location • 3925 West Braker Lane, Suite 200, Austin Tx, 78759 • Details: Development of an easily deployable mechanism to apply downforce on 2014’s drill design. • Specifications • Capability of applying sufficient force to drill up 20 meters deep • Compatibility with existing technology supplied by NASA • Design allows for core sample extraction • Minimal cost MISSION STATEMENT Designing and manufacturing of an easily deployable mechanism that is capable of applying extensive downwards force on the previously designed drill bit, removing the need for relocating the drill on the spacecraft or increasing the overall weight. Need Statements Related to Importance Target Specifications and Metrics Specifications 1.Sufficient Force 2.Uses available power source 3.Withstands drilling force 4.Compatibility 5.Counter drilling force 6.Easily retrieved 7.Simple to use Metric 1. 2. 3. 4. 5. 6. 7. Force Target, Force applied on bit : lbs Electricity, Volts/Watts Strength, psi General Design and dimensions, in Torque, Force, N*m lbs N/A Linking Metrics to Needs Gantt Chart Important Dates ● 9/11 - Discussion with Mandell ● 9/28 - TSGC level I report ● 10/6 - Concept Selected ● 10/16 - Make Buy Decisions ● 10/16 - CAD models ● 10/15 - Process management ● 10/30 - Begin Fabrication ● 11/16 - Final Report and Presentation to TSGC Concept Generation Concept Variants Pugh Chart Concept Selection Matrix Scissor Jack Windows Scissor Jack • Critical Customer Needs Met: • Applies down force • Anchors mechanism • Resists torque of drill • Functional in elements • Uses available power source • Simple to Use FMEA (Failure Mode & Effects Analysis) Bill of Materials (BOM) Scissor Jack (Components) Route Sheet OPC (Operation Process Chart) PERT Chart ● Design finalization, processing, OPC, and materials ordering should be ran in parallel to ensure parts arrive in time ● Due to research, concept generation and selection took the longest amount to time. ● Assembly has the shortest duration Process Name X # Duration (days) Manufacturing Process Prototype Testing (FEA) ● Applied 90lb force on lead screw ● Used Von Mises Stress to verify part strength ● Stress seen by lead screw, about 97psi ● Stress seen by links, about 100psi SWOT Analysis Future Considerations and Designs • The addition of gear teeth to ensure linkage pairs remain aligned and stabilized throughout linear travel. • Identification of elastic material to protect from elements entering the gripper window and electrical input port. Acknowledgements Questions?