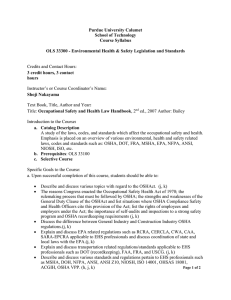

OSHA's Mission

advertisement

Rules and Regs OSHA regulations must be enforced within your operation Most pizzeria operators believe “inspection” describes a Registered Sanitarian stalking health code violations in kitchens, walk-in coolers and washrooms. But equal attention should go to another safety agency whose compliance officers may soon scrutinize pizzerias as never before. We’ve all heard about the Occupational Safety and Health Administration (OSHA). Some of us even have safety compliance inspection tales for anyone who dares mention their last health department visit. But the restaurant industry generally dismisses OSHA as a watchdog suffering tunnel vision, intent on construction and high-hazard industries. Maybe, but try convincing the Ohio pizzeria owner who was penalized $14,000, or the one in Maryland fined $6,700, or the folks in Michigan who shelled out $5,000. That’s in addition to the cost of correcting violations. Contrary to popular belief, OSHA monitors more than “hard hat” occupations — and with good reason. Most telling is the growing number of workers in service industries, a term synonymous with restaurant. This dynamic may increase accident rates and draw regulatory attention. Here’s an excerpt from OSHA’s new Strategic Management Plan: The American workforce has changed in significant ways over the past several decades. It is more diverse in terms of age, gender, race and nationality. The products of labor are increasingly services rather than goods. A smaller percentage of workers are employed in large fixed industries, and higher proportions are employed in small firms, temporary jobs or at home. More work is now contracted, outsourced and part time. These trends are expected to continue over the next several decades and will require different strategies to address developing issues. Thus, OSHA assures restaurant employees it will deal with injury and illness resulting from America’s changing workforce. Rich Fairfax, OSHA's director of enforcement programs, calls the Strategic Management Plan “a balanced effort to address workforce changes through enforcement, education and employer assistance.” It’s important to note that today’s OSHA assumes the role of educator and consultant, but keeps compliance inspections around as an integral weapon in its arsenal. Fairfax is sincere when he says OSHA wants to work with service industry employers. Therefore, perhaps the restaurant industry should listen and, in the process, learn more about the agency too many folks love to hate, usually with consequences including high accident rates, lost workdays or violation penalties. OSHA’s Mission OSHA has one job and jurisdiction: protect America’s 100 million workers. To accomplish that, the agency develops safety standards, offers consultation and enforces regulations. Pick a Card…Any Card The question anxious employers ask most frequently is: “How does OSHA decide who to inspect?” Surprise! Neither rolling dice nor spinning wheels determine the answer. Instead, OSHA inspectors follow a published priority system: Imminent Danger to Life and Health reports receive priority so OSHA can abate unsafe conditions before death or serious injury occur. Fatality/Catastrophe accidents claim second seed so OSHA can quickly correct contributing conditions and assure workers the locations is safe. Any workplace experiencing fatality or catastrophe (three or more workers hospitalized) must report the accident to OSHA within eight hours. Employee Complaint ranks third, but generates most restaurant inspections. Warning lights should be flashing right now for those who caught the line about growing numbers of workers generating more complaints. Planned Inspections are based on industry type, accident rates and emphasis programs. Logging, for example, is a special emphasis industry in Minnesota. Loggers automatically maintain increased interaction with OSHA. Fairfax believes restaurant operators may soon experience inspections driven by a national Emphasis Program that targets amputations. He says, “Powered slicers are one of the four machines the programs covers.” Head’s up folks! If your employees operate slicers, it’s time to learn about standards covering machine use and guarding. Follow-Up Inspections ensure abatement of previous violations. Fairfax’s statistics show the five most commonly cited violations in restaurants are: Hazard Communication Walking and working surfaces Personal protective equipment (gloves, aprons, eye protection) Electrical (circuit and wiring design, extension cords) Fire protection (fire extinguisher availability, use and training) Compliance Inspection Basics Compliance officers arrive unannounced, present credentials and conduct an Opening Conference outlining reasons for the visit and discussing the inspection process. Following the conference, the inspector, management and employee representative tour the workplace. The office takes notes, snaps photographs and questions employees about work conditions and practices. Finally, a Closing Conference addresses violations, abatement methods and dates and employer right-to-contest. The inspector then returns to the OSHA office, researches standards and issues appropriate citations and penalties, which employers receive via certified mail. An employer receiving a citation package may pay penalties as ordered or file a notice of contest. The appeal process begins with an informal hearing between OSHA and the employer, which settles most cases. Abatement dates may also be appealed. Keeping Up With Standards Staying current with safety standards is difficult, but free assistance is available. OSHA’s Web site, www.osha.gov, is packed with information. You’ll find laws and regulations, statistics and training aids. Test-drive the Expert Advisor software employers can use to self-analyze compliance status regarding issues like fire prevention. Rich Fairfax is enthusiastic about OSHA consultation services, which offer employers free workplace evaluations and other assistance. Plus consultation clients usually receive temporary exemption from compliance penalties. Pizzeria operators belonging to industry associations should determine if their organization is an OSHA Alliance partner, a program that offers special assistance for member employers. Larger pizzeria companies should explore the benefits of OSHA Alliance partnership. For more information, call (800) 321-6742. It’s Up To You Tighter control is coming, which means pizzeria operators have to pile more stuff onto already overflowing plates. But, workplace safety is important and nobody else will do the job. Besides, consider the benefits. Informed operators who take reasonable precautions enjoy fewer employee injuries and illness, smaller medical expenses and greater productivity. And, they’re more likely to avoid complain-generated inspections or survive OSHA visits unscathed. That all bolsters the profit line, so get moving and work safely! —Gary Midge