Throughput Assignment

advertisement

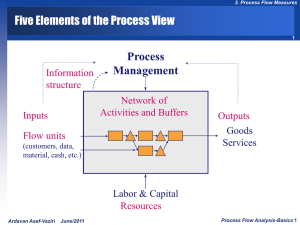

Throughout Problems 5.4. The Process Flowchart from Problem 4.4 2 min molding 1 min welding aut. molding machine 3 min eng. ass. 1 engine assembler 1 molding operator 1 min 3 min stamping welding start 30 min continuous welding machine FA 1 welder end 2 min stamping 10,000lbs press 10 final assemblers 1 press operator 7 min seat ass. 2 seat assemblers Throughput Problems – Set2 Ardavan Asef-Vaziri Nov-2011 2 5.4. The Process Flowchart from Problem 4.4 Resource Pool Molding machine Molding operator 10,000lbs press Press operator Welding machine Welder Engine assembler Seat assembler Final assembler Throughput Problems – Set2 Theoretical capacity of a Number of Unit Load resource unit resources [min/job] [jobs/hr] in pool 2 30 1 2 30 1 3 20 1 3 20 1 4 15 1 4 15 1 3 20 1 7 8.57 2 30 2 10 Ardavan Asef-Vaziri Nov-2011 Theoretical Capacity of Resource pool/hr 30 30 20 20 15 15 20 17.14 20 3 5.4. The Process Flowchart from Problem 4.4 Unable to meet demand for this bike, Honda wants to increase throughput. A team member suggests cross-training the engine and seat assemblers. This suggestion should not be implemented because these resources are non-bottlenecks and therefore do not impact system throughput. We suggest increasing bottleneck capacity by decreasing welding times by design or process improvements. Other options are buying another welding machine and adding another welder, outsourcing some welding. Throughput Problems – Set2 Ardavan Asef-Vaziri Nov-2011 4 Problem 5.5 5.5 – NewLife Finance handles two types of claims: hospital and physician. NewLife charges the HMOs $10 per hospital claim (HC) and $9 per physician claim (PC). The variable costs per claim are negligible. The theoretical capacity of the process is 375 claims per day in the case of HC and 545 claims per day for PC. a. What of the two types of claims is more profitable for NewLife? b. Assume that the maximum number of PCs available for processing per day is 400. What is the best product mix for NewLife? Throughput Problems – Set2 Ardavan Asef-Vaziri Nov-2011 5 Problem 5.5 (a) PC:is the more profitable product: The profit from HC is 10×375 = $3750 per day. The profit from PC is 9 × 545 = $ 4905 per day (b) Assume 480 minutes per day. The unit load for HC is 480/375 = 1.28 minutes per claim. The unit load for PC 480/545 = 0.88 minutes per claim. The time to make 400 PC claims is then 0.88 × 400 = 353 minutes per day. This leaves 480-353 = 127 minutes for HC. At 1.28 minutes per unit, this allows for 127/1.28 = 99.8 (roughly 100) units. The best mix is 400 PC and 100 units of HC per day. (80% and 20%) Throughput Problems – Set2 Ardavan Asef-Vaziri Nov-2011 6 Total Unit Load for Product mix Compute the unit load and the total unit load for each Load batch of Regular tile, Jumbo tile and a product mix of 75% Regular and 25% Jumbo . Load Batches are 4 and 9 for regular and jumbo, respectively. Set-up Batches are 300 and 100 for regular and jumbo, respectively. Product L -Batch S-Batch Cutting time Setup time Regular 4 units 300 L-batch 2 min/L-batch 30 min/S-Batch Jumbo 9 units 100 L-batch 1 min/L-batch 30 min/S-Batch Unit Load (Tp ) Sp/Qp Total unit load Throughput Problems – Set2 Regular 2 30/300=0.1 2+0.1=2.1 Jumbo 1 Mix (2×0.75)+(1×0.25)=1.75 30/100=0.3 (0.1×0.75)+(0.3×0.25)=0.15 1+0.3=1.3 (2.1×.75)+(1.33×.25)= 1.9 Ardavan Asef-Vaziri Nov-2011 7 Effective Capacity of a Resource Unit Theoretical Capacity of a resource unit = (1/Unit Load) × Load Batch × Scheduled Availability Scheduled Availability – the scheduled time period during which a resource unit is available for processing flow units. Availability factor = Net Availability/Scheduled Availability Effective Capacity of a resource unit = (1/Total Unit Load) × Load Batch × Scheduled Availability Effective Capacity of a pool = (c/Tp) × Load Batch ×Scheduled Availability Throughput Problems – Set2 Ardavan Asef-Vaziri Nov-2011 8 Problem 5.6 5.6 – Recall from this chapter that the Tile&Style Company produces kitchen and bathroom tiles in two sizes: jumbo and regular. A bundle of tiles contains 4 jumbo tiles or 9 regular tiles and is cut out of single, larger plate. The cutting time per bundle is 1 minute for jumbo and 2 minutes for regular. Currently, 75% of the bundles are regular, and 25% are jumbo. Typically, Tile&Style produces 300 bundles of regular tiles before it switches over and produce 100 bundles of jumbo. The switching time from one size to the other is 30 minutes in both directions. Plates are cut into tiles by a cutting machine that is available 8 hours per day. The availability loss factor is 20%. a. Compute the theoretical capacity of the process (bundles per hour) b. Compute the effective capacity of the process (bundles per hour) Throughput Problems – Set2 Ardavan Asef-Vaziri Nov-2011 9 Problem 5.6. Th Unit load S/Q Unit load Regular 2 0.1 2.1 Jumbo 1 0.3 1.3 Mix 2×0.75+1×0.25 0.1×0.75+0.3×0.25 2.1×0.75+1.3×0.25 Mix 1.75 0.15 1.9 Theoretical Capacity = 480/1.75 = 274.3 Aggregate Product Effective Capacity = .8(480)/ 1.9 = 202.1 Aggregate Product What is an aggregate product? It is 0.75 Regular and 0.25 Jumbo Therefore; 202.1 aggregate is 151.57 regular bundle and 50.52 Jumbo bundle: 9(151.57) , 9(50.52). Throughput Problems – Set2 Ardavan Asef-Vaziri Nov-2011 10