safety in the pharmacy

safety in the pharmacy

•what is 6th leading cause of death?

•7000 fatalities/year from adverse drug reactions.

The FDA, in a compilation of reports from 1998 to 2005, found that dangerous side effects and deaths from prescription and over-the-counter medications almost tripled to nearly 90,000 incidents

•100000(in 1999) fatalities/year from medical errors(400,000?now)

•celebrities who have been killed by pharmaceutical mistakes, overdoses, etc?

most common?---insulin, narcotics, opiates, methotrexate, warfarin, kcl injection drug use kills more people than MVA now.

ADE=adverse drug event

ADR=adverse drug reaction

Medication errors handwriting, wrong patient, language, wrong strength, wrong calculation, wrong sig,overworked, sound alike, look alike names, pt noncompliance, ect errors have categories--show chart tell pharm stories--medication reconciliation---process to find the most current meds of a patient--show form pg 354

safety in the pharmacy

• A. Personal safety

• 1. Safety from physical harm

• a. substances

• b. supplies (chemicals, poisons, etc.)

• c. equipment

• d. improper body mechanics

• 2. Employee responsibilities

• a. maintain a safe work place

• b. apply principles of proper body mechanics

• c. wear appropriate PPE (Personal Protection Equipment)

• d. follow proper procedures in handling pharmaceutical agents that may pose a hazard to the practitioner

• e. know where to locate the material safety data sheets (MSDS)

• f. know and apply policies and procedures in case of

• emergency

• i. fire safety

• ii. chemical spills and other hazardous materials

• iii. body fluids

• iv. standard precautions

• v. equipment maintenance and failure

• vi. internal disasters (fire, robbery, bomb threat, etc.)

• vii. external disaster (weather related, traffic disaster, etc.)

• Environmental Safety

• 1. Clean work place

• 2. Proper ventilation

• 3. Proper lighting

• 4. Adequate set-up and layout of work place

• 5. Properly functioning equipment

• 6. Well trained employees aware of potential hazards

• Occupational Safety and Health Administration (OSHA)

• 1. Workplaces may be inspected by OSHA officers without prior

• announcement in order to accomplish intent to decrease hazards

• in the workplace and maintain a reporting system for monitoring

• job-related injuries and illness

• 2. They develop mandatory job safety and health standards

• Joint Commission on Accreditation of Healthcare Organizations

• (JCAHO)

• 1. Pharmacy standards of JCAHO provide quasi-legal standard of practice for the profession

• 2. In court of law practice standards define accepted professional practice and assume quasi-legal status

• 3. Pharmacies must meet strict standards in order to be accredited by JCAHO

• 4. Accreditation is voluntary but important if business is interested in dealing with third party payers who require certification through accreditation process, e.g. Medicaid, etc.

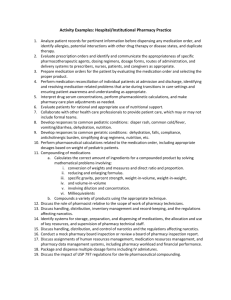

• Pharmacy must ensure

• 1. Right drug – always double check the label on bulk bottle for

• strength and correctness

• 2. Right patient

• 3. Right dosage

• 4. Right route

• 5. Right time

• 6. Right attitude

• Practitioner must be familiar with

• 1. Common side effects

• 2. Contraindications

• 3. Drug or food reactions with medications

• 4. Generic drugs that may be substituted

• D. Practitioner should know at minimum the following information for the drugs most used in individual practice setting or geographical location

• 1. Adverse drug reactions

• 2. Side effects

• 3. Contraindications

• 4. Drug/food interactions

• 5. Safe/effective dosage range

• 6. Common dosage regimens

• 7. Dosage forms

• 8. Route of administration

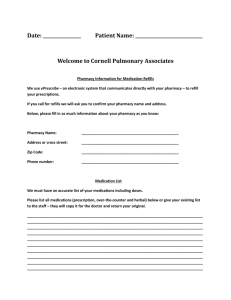

• E. Reviewing Refills

• 1. Number of refills

• 2. Correct drug selection

• 3. Significantly early or late requests for refills may indicate

• medication misuse

• Beware of dispensing errors

. Proper storage of pharmaceuticals

• 1. Store in original container until dispensed

• 2. Follow manufacturer’s directions for proper storage

• 3. Follow proper disposal of expired drugs

• a. deteriorated drugs are ineffective

• b. deteriorated drugs may be a hazard if a condition not treated appropriately

• c. deterioration may cause chemical changes leading to dangerous reactions

• All schedule II drugs must be kept under lock and key.

With schedule III, IV, and V drugs, lock and key storage is optional but suggested

manufacturing label has a bar code somewhere----bottle comes to pharmacy with many pills inside. label gives generic and brand name, how many, strength,NDC code, lot#, expiration, instructions.

prescription label has bar code somewhere---bottle to patient. has pt name, dr name, drug name, refills,sig, pharmacy name accuracy scanner--- a quick scan tells if the rx label and manufacture label have same drug.

medication counter---quickly counts pills that are not see through.

not to be used for sulfa drugs and amoxicllin due to residue.

or use spatula and counting tray. count 3 or 5 at a time.

put into bottle…child safety cap?

pharmacist does verification of the drug.