training - California State University, Fresno

SUPERVISOR’S SAFETY

TRAINING

PART 1:

IIPP, Haz Com, and Emergency Plan compliance basics

On-the-job injury/illness statistics

Bureau of Labor & Statistics 2005:

5,702 workplace deaths in US

16 workers avg. fatally injured/day

More than 4.2 million injuries & illnesses reported in private sector

453 workers fatally injured in

California

Costs…

Employee:

Pain & Suffering

Loss of Wage

Company:

Medical/workers’ comp insurance rates

Loss of productivity

Product/equipment damage

National Safety Council: $27,000 per incident; work-related death $780,000

OSHA General Duty Clause:

Gives the agency wide powers in its enforcement activities.

“

Each employer:

1.

shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees

2.

shall comply with occupational safety and health standards promulgated under this act.

(b) Each employee shall comply with occupational safety and health standards and all rules, regulations, and orders issued pursuant to this Act which are applicable to his own actions and conduct.”

Supervisor/Manager

Responsibilities

Identify, eliminate or minimize hazards.

Ensure employees obtain required training before beginning work.

Investigate accidents to determine causal factors, and implement corrective actions.

Provide supervision to ensure employee compliance with safety rules and procedures.

Implement disciplinary actions when necessary to correct unsafe work behaviors.

Corporate Criminal Liability Act

“ Be a Manager, Go to Jail”

California Penal Code, Section 387

Enacted in 1990 by the California legislature. This law is designed to protect workers as well as the public.

Makes organizations and their managers criminally liable when they fail to warn their employees and report to Cal-OSHA the existence of “serious concealed dangers of which the corporation and its managers have actual knowledge…”

Investigations can be long and involved.

Convictions can involve fines and/or imprisonment.

Corporate Criminal Liability Act cont.

Definition of a manager…

A person having both:

1.

Management authority and

2.

Significant responsibility for any aspect of a business including safety of a product/business practice (Employers, directors, management officials, supervisory personnel)

Note: you do not have to have the words

“manager” or “supervisor” in your title for you to be considered as a manager.

Corporate Criminal Liability Act cont.

Definition of a Serious Concealed Danger…

A danger related to a product or business practice, that creates a substantial probability of death, great bodily harm, or serious exposure to an individual.

Recent Changes at Cal/OSHA:

State agencies, such as Universities and Colleges become subject to OSHA fines starting January

2000.

Proposed penalties increased from less than $1 million in 1999 to over $29 million in 2006.

Employers criminally prosecuted for workplace accidents (recent: 9-year prison term; probation + high six-figure penalty).

Calif. Supreme Court ruling:

Cal/OSHA standards are admissible in any civil proceedings to define standard of care in negligence lawsuits.

What triggers an OSHA visit?

Death or serious injury

Employee complaint (can be anonymous)

Another agency referral

Recognized high hazard industry

Random inspection

Important note: If you are visited by an OSHA enforcement officer, do not turn them away. Ask them to wait and contact EH&S immediately for assistance.

Injury and Illness Prevention

Plan (IIPP)

The IIPP is the “umbrella” safety program that details how the organization will protect employees from hazards in the workplace.

The University has a campus-wide

IIPP, and most departments have their own departmental IIPP.

Check with your department safety coordinator to see if a departmental

IIPP has already been established.

What are the eight components of a model IIPP?

Responsibility

Compliance

Communication

Hazard Assessment

Accident/Exposure Investigation

Hazard Correction

Training and Instruction

Recordkeeping

The next few slides will provide information regarding

each component.

RESPONSIBILITY COMPLIANCE

Who is the

Program

Administrator?

Usually the individual at the highest level.

Who is charged with the responsibility for maintaining the

IIPP?

How will compliance be assured?

Providing info and training to employees

Evaluating safety performance

COMMUNICATION

How will your department handle communication with employees about safety?

Handouts

Posters

Emails

Face-to-face discussions/training

Meetings

On-line training

HAZARD ASSESSMENT

Methods for discovering and correcting hazards in the workplace…

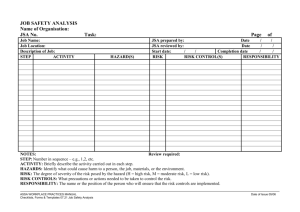

For task/job hazards:

Job Safety Analysis (JSA)

Usually completed by the Supervisor, unless assigned to subordinate.

For work environment hazards:

Job site inspections:

Find hazards and eliminate or minimize them before the job is performed!

Misc. hazards:

Accident Investigations

Employee reports:

Employees should be encouraged to report hazards to the supervisor or EH&S as soon as possible. Form is available for employees to do this anonymously.

Job Safety Analysis (JSA)

Which jobs/tasks to pick first?

-

Set priorities based on:

Review job description/duties

Jobs or tasks that have caused accidents.

Jobs or tasks involving near-misses.

New jobs.

Jobs that have undergone changes in procedures, processes, or equipment.

JSA cont.

Other considerations when prioritizing:

-

-

-

Industry information

OSHA High Hazard listing

OSHA regulations specific to the work

JSA cont.

How do you complete a JSA?

Involve the employees who complete the work and their supervisors

Break tasks into sequence of steps or movements

Identify the potential hazards associated with each step

Recommend Action or Procedure to eliminate or minimize each identified hazard

JSA cont.

What’s next?

Share completed JSAs w/ supervisor and employee

Implement recommendations to minimize/eliminate identified hazards

Engineering controls

Administrative controls

Personal protective equipment

Develop procedures and train employees

Keep a file of all JSAs

Periodically review for new tasks/hazards

Hierarchy of Control

Keep this in mind when choosing control solutions for identified hazards .

Your ability to control hazards decreases as you go down the following list of solutions…

Substitution/Elimination

Engineering

Administration

Personal Protective Equipment

Hierarchy of Control cont.

Substitution/Elimination

Can the work be completed in a way that the hazard can be completely eliminated?

Can you replace the hazard with something less hazardous, and still get the job done?

Example: replace a organic solvent cleaner with an non-toxic citrus-based cleaner.

Hierarchy of Control cont.

Administration

Can you limit employee exposure through scheduling of work?

Example: Can you limit the amount of time employee is exposed using the employee’s work schedule?

Watch out for the need for administration pitfalls!

Workload requiring extra work time

Peer absences

Hierarchy of Control cont.

Engineering

Can the hazard be eliminated or mitigated through remodeling/revamping equipment?

Example: Surround a process that creates loud noise with a sounddampening enclosure.

Hierarchy of Control cont.

Personal Protective Equipment

Unpopular with employees, often uncomfortable.

Requires increased level of supervision to ensure proper use and maintenance.

Job Site Inspections

Complete regular job site inspections.

Frequency will depend on level of safety hazards.

Most administrative office spaces need only an annual inspection.

Labs: monthly/quarterly

Construction/mfg: daily/weekly

ACCIDENT/EXPOSURE

INVESTIGATIONS

(Note: EH&S will be assisting with this process)

Procedures for investigating incidents include:

Interview injured employees and witnesses.

Examine the workplace for causal factors.

Take corrective action to prevent reoccurrance.

Record the findings and actions taken.

HAZARD CORRECTION

…

Must be done in a timely manner…

When observed or discovered; and

If the hazard can’t be fixed in a timely manner, determine if:

the piece of equipment should be tagged out “unsafe – do not use” employees need to be removed from the area until it is safe to return.

TRAINING

Common threads leading to injuries:

Lack of knowledge

Unfamiliarity with equipment

Incorrect performance of task

Training and proper supervision to ensure tasks are completed properly can reduce the risk of injury.

TRAINING cont

.

Step 1: Determine which training is necessary .

Complete a Job Safety Analysis.

Ask employees to describe job procedures.

Observe employees as they work. Ask questions.

Review accident reports/records

Consult with EH&S Workers’ Compensation Coordinator regarding previous injury statistics in your department

Review industry information

Are there practices or operations that have not led to accidents in your organization, but have led to accidents elsewhere (other departments, other Universities)?

TRAINING cont

.

Step 2: Determine scope of training.

All employees

Employees in a particular workspace

Employees who work with or near hazardous chemicals or substances

Employees who work with or near a hazardous piece of equipment

Supervisors

TRAINING cont

.

Step 3: Identify goals and objectives

Step 4: Conduct the training and collect/maintain documentation.

Step 5: Provide refreshers as needed

TRAINING cont

.

1.

2.

3.

Every employee must receive training regarding:

4.

5.

The existence of the campus IIPP

The departmental IIPP

The department Emergency Plan and campus emergency and evacuation procedures.

Hazard Communication (Chemicals)

Job Specific hazard training

This training should be completed before beginning work .

TRAINING cont

.

1. Existence of campus IIPP

Provide a link to the campus plan so that they may download it.

http://www.csufresno.edu/ehs/policies.htm

Questions about the campus plan should be directed to EH&S

TRAINING cont.

2. Departmental IIPP

Review all components of the departmental IIPP with the employee.

Provide employee with a copy.

TRAINING

cont.

3.

Department Emergency Plan

Review & provide a copy of your department emergency plan.

Emergency escape procedures/routes

Preferred means for reporting fires/other emergencies

Names/job titles of ees/departments to contact for further info

If applicable: procedures to be followed by ees remaining to operate critical operations before evacuating

If applicable: rescue/medical duties for key ees

TRAINING

cont.

3.

Emergency and Evacuation Procedures

Provide link to campus emergency procedures handbook.

http://www.csufresno.edu/police/emergenc y.htm

Have the employee complete the

Campus Emergency Evacuation

PowerPoint training.

TRAINING cont.

4. Hazard Communication

Every employee has a “Right to Know” about chemicals.

The Hazard Communication Standard

(HazCom) was created by Cal-OSHA to provide individuals with information about the chemical hazards on the job, and how to protect themselves against those hazards.

HAZARD COMMUNICATION cont.

Chemicals are hazardous if they:

Cause acute health problems

(such as corrosives that can burn eyes or skin)

Cause chronic health problems

(such as toxic chemicals that can cause long-term illnesses, such as cancer)

Suddenly release pressure

(these explosive chemicals includes gases that could expand violently

Are flammable/combustible

(chemicals that catch fire easily)

Are reactive

(these chemicals are not stable, and thus can burn, explode, or release dangerous vapors if exposed to heat, air, water, or particular other chemicals.

HAZARD COMMUNICATION cont.

The HazCom Standard details threepronged compliance:

1) Chemical manufacturers are required to:

determine the physical and health hazards of each product they make. provide detailed container labels and supply Material Safety Data Sheets (MSDS)

HAZARD COMMUNICATION cont.

2) Employers are required to:

Make MSDS’s available to employees

Provide employees with training about the

Hazard Communication Standard

Explain how it’s being put into effect in their workplace, including:

How to recognize, understand and use labels and MSDSs

Using safe procedures when working with hazardous substances

HAZARD COMMUNICATION cont.

3) Employees are required to:

Read labels and MSDS’s

Follow label and MSDS instructions and warnings.

HAZARD COMMUNICATION cont.

How do I find MSDS’s?

Look up your chemical at www.msdsonline.com

Username: csuf

Password: bulldog

Call the chemical/product manufacturer or distributor.

“Google” your chemical/product or distributor

Call EH&S for assistance.

HAZARD COMMUNICATION cont.

Next steps…

Complete a chemical inventory.

Obtain Material Safety Data Sheets

(MSDS) for each chemical used or stored in your department. MSDS’s must be available to the employee.

Ensure that employees receive appropriate training.

Hazard communication cont.

Training…

Determine the level of training needed

Level 1: High chemical use/exposure potential

(Research/laboratory, Ag or Grounds Maintenance)

Consult with EH&S for training.

Level 2: Medium chemical use/exposure potential

(Plant Operations/Maintenance)

Consult with EH&S to training.

Level 3: Minimal chemical use/exposure potential

(Administrative/Office work/Non-lab teaching)

See outline of necessary training on next slide.

Hazard communication cont.

Training…

Level 3

Provide training on:

Location of your MSDS files (must be available to the employee at will)

Right to know law*

Precautions to follow*

How to read labels*

How to read MSDSs*

*

Training handouts available from EH&S

DOCUMENTATION

Document everything. If you don’t have a record of it – it didn’t happen.

“Training” can be as detailed as a 40-hour class or simply a 5-minute safety talk at the end of a department meeting

have everyone sign in for every meeting

If info is distributed via email – keep a copy w/the distribution list

Must attach an outline of the information covered and/or handouts

Utilize documentation forms already developed

DOCUMENTATION cont.

The following documentation forms have been developed for your use:

Employee safety/emergency procedures training record

For documenting initial training on IIPP, Emergency procedures, HazCom and Job-specific training

Safety Training Attendance Record

For documenting subsequent training

Safety Committee Meeting (if applicable)

Report of Unsafe Condition or Hazard

Provides employees with an anonymous method for reporting hazards.

Hazard Correction Report

For documenting corrections to identified/reported hazards.

Next steps…

Keep up to date with training new employees.

Provide trained employees with refreshers regarding IIPP;

Emergency Plan; Hazard

Communication; job-specific hazards

Review job tasks to determine the need for JSA’s