INDUSTRY

advertisement

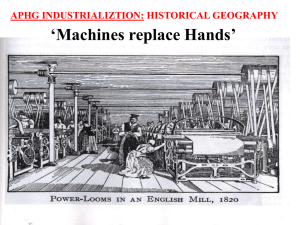

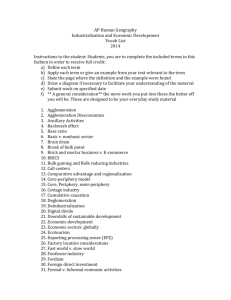

INDUSTRY Rachel Meggers and Ben Seely INDUSTRIALIZATION: The growth of manufacturing activity in an economy or a region Characterized by a decreasing number of subsistence farmers as they leave the agriculture sector for manufacturing jobs Major Economic Classifications Primary Sector (ex: fishing, farming) - Activities that revolve around extracting raw materials from the earth Secondary Sector (ex: factory worker, manufacturing) - Activities that deal with processing the raw materials into a finished product Tertiary Sector (ex: bank tellers, carpet salesman) - Activities or service that move, sell, and trade the products made in the second sector Quaternary Sector (ex: university researcher) - Activities that involve information creation and transfer Quinary Sector (ex: legislatures, CEOs) - Activities that involve the highest level of decision making Diffusion of 5 Characteristics Industrialization of Industrialization Cottage industries, before the Industrial Revolution, were where people made tools and equipment in their own home INDUSTRIAL REVOLUTION: A series of improvements in industrial technology that transformed the process of manufacturing goods The Industrial Revolution began in England in the 1760’s as a period of rapid socio-economic change and mass exploitation of workers Machines replaced human labor New source of energy found Beginnings of assembly-line production Transportation improved Farming became mechanized Industrial Regions Europe: UK – used to be steel and coal, now high-tech Moscow – fabrics, and product with skilled labor St. Petersburg – shipbuilding, Navy industries United States: New England – oldest in U.S., textiles Middle Atlantic – Largest U.S. market Mohawk Valley – steel and food processing Pitts- Lake Erie – steel 19th century Western Great Lakes – transportation and steel Southern Cal.- 1940s – aircraft SE Ontario – Canada’s most imp., steel East Asia: Japan (1950s and 60s) – automobiles, ships, cameras, stereos, TVs China – low cost labor, largest consumer market Weber’s Least Cost Theory of Industrial Location Predicts where factories would choose to locate based on the places that would be the lowest cost to them Considers two issues: Distance of transportation to market Weight of goods being transported Weber’s Model Assumptions Transportation cost is solely determined by the weight of the goods being shipped and the distance they are being shipped Labor exists only in certain places and is not mobile Markets are in fixed locations Industries are competitive and aim to minimize their costs and maximize their profits Physical geography and political/cultural landscapes are assumed to be uniform across the model’s space Weber’s Model Assumptions With the assumptions, location of industry is driven by four factors: Transportation Labor The theory does not identify the fact that markets and labor are often mobile and that the labor force varies in age, skill sets, gender, etc. Some transportation costs are not in fact directly proportional to distance Agglomeration (spatial clumping in industry) Deglomeration (spatial “unclumping” in industry) Weber’s Model Critics Weight-Gaining Industries Weight-Losing Industries Manufacturing processes that that take the raw materials and create a heavier final product Manufacturing processes that take the raw materials and convert them into a lighter final product Typically locate near the market. Typically located closer to raw materials “bulk-gaining” Ex: beverage bottling, fabricated metals “bulk-reducing” Ex: paper production, copper, steel US Steel Industry Principal inputs: Iron ore and coal Centers of Steel Production: “Rust belt” (Pennsylvania, Ohio, Michigan, etc.) Mid 19th century: Pittsburgh, PA Late 19th century: Lake Erie and Ohio cities Early 20th century: Lake Michigan Mid 20th century: closer to oceans on both coasts Bulk-reducing industry Footloose Industries have spatially fixed costs and are not affected by transportation costs Often produce lightweight products of high value, ex: computer chips Transportation The farther something is transported, the cheaper the cost Trucks (short distances, load/unload quickly) Trains (ship to destinations, longer to load and travel) Air (most expensive, speedy delivery of small-bulk, high-value items) Ships (long distances, international, slower than land Break-of-bulk point: Location where transfer among modes of transportation is possible, where two or more transportation modes meet Ex: seaports and airports Substitution Principle Weber’s model assumes that the cost of labor is a key factor that influences where industries choose to locate It also includes the availability of industrial capital: machinery and the money to purchase the tools and workers the factory needs Substitution principle is applied when an industry moves to access lower labor costs, even though transportation costs might increase as a result In the long run, theses companies will save more because of the cheaper labor Labor Intensive Industries One in which the wages and other compensation paid to employees constitute a high percentage of expenses Ex: textile and apparel industry Agglomeration Deglomeration Occurs when industries clump together in the same geographic space Factories can then share costs associated with resources such as electrical lines, roads, pollution control, etc. “Unclumping” of factories because of negative effects and higher costs associated with industrial overcrowding When agglomeration negatively affects the industries in ways such as pollution, traffic congestion, or overused resources and labor Backwash effects are negative consequences of agglomeration that can occur when areas suffer brain-drain of talented people who are moving to a technopole or other center of industrial agglomeration Future of Industry Industry is shifting away from traditional areas of northeastern US 2 million jobs added to the “sun belt” between 1950 and 2009 South has lower wages and little interest in joining unions International shifts in industry to Brazil, China, and India BRIC = Brazil, Russia, India, China Outsourcing has effected the distribution of manufacturing Maquiladoras: foreign owned factories located in Mexico Located close to the US border and major cities Located in Mexico because of cheap labor, NAFTA, Mexico’s proximity to the US market, and improved transportation Helpful Review Links http://quizlet.com/20184677/ap-human-geography-chapter-10-vocabularyflash-cards/ http://www.flashcardmachine.com/ap-humangeographyindustryvocab.html