industrial capital

advertisement

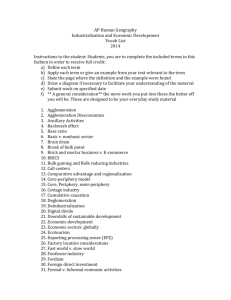

Industrialization Defining Industrialization • Definition – The growth of manufacturing activity in an economy or a region • Usually industrialization is accompanied by a decrease in the # of subsistence farmers in a country or region as they leave the agricultural sector in favor of manufacturing jobs Major Economic Classifications • The economy is the system of production, consumption, and distribution in a region • Classifications – Primary sector • Part of the economy in which activities revolve around getting raw materials from the earth – Ex: Fishing, Farming – Secondary sector • Economic activities that deal with processing the raw materials into a finished product of greater value – Ex: Factories, Manufacturing – Tertiary Sector • Economic activities or services that move, sell, and trade the products made in the 1st two sectors – Ex: bank tellers, carpet salesman – Quaternary Sector • Economic activity that involves information creation and transfer – Ex: University researcher – Quinary Sector • Economic activities that involve the highest level of decision making – Ex: Legislatures, CEOs Diffusion of Industrialization • Prior to the Industrial Revolution – People made household tools and agricultural equipment in their own home or obtained them in a local valley • Called cottage industries • Characteristics – Machines replaced human labor • Root of IR was technology – – – • Definition of Industrial Revolution – A series of improvements in industrial technology that transformed the process of manufacturing goods – New sources of energy found • Coal leading source – • History of the Industrial Revolution – Began in England in the 1760s • Period of rapid socio-economic change Several inventions that transformed the way goods were manufactured Result in unprecedented expansion in productivity Industries impacted » Iron, Coal, Transportation, Textiles, Chemicals, Food Processing Major cities rose up near coal fields – Beginnings of assembly- line production • Small-scale, mechanized factories – Transportation improved – Farming became mechanized • Results – Higher standards of living, stage 2 DTM Diffusion of Industrialization • Commodification of labor – One result industrialization – Factory owners began looking at their human labor as commodities (objects for trade) with price tags per hour, rather than seeing workers as people • Spread of the Revolution – By 1825, the technology of industrialization had spread to North America and Western European countries • Thrived in areas with rich coal deposits • By the 1920s the production process in the U.S. automobile factories had broken down into differentiated tasks to complete the product – Process known as the Ford (Fordist) production method • Built factories “out” rather than “up” so they factories were only one story and the product could be transported through the assembly line with no problems • Based on division of labor – where different parts of the assembly process were divided up among different workers and areas of the factory Diffusion of Industrialization Industrial Regions • Concentrated in three regions – Europe, North America, East Asia – Outside the region include Brazil and India • Europe – – – – – – – – – – – – UK – used to be steel/ coal, now high-tech Rhine-Ruhr Valley- Iron/Steel Mid-Rhine- 2nd most imp. Industrial area Po Basin- oldest, most imp. Industrial area NE Spain- fastest growing, textile, autos Moscow- fabrics, and product w/ skilled labor St. Petersburg- shipbuilding, Navy industries Volga- petroleum and natural gas Urals- more than 1,000 minerals Kuznetsk- Russia’s most imp. manufacturing Donestk- iron/steel (largest in E. Europe) Silesia- Poland and Czech Rep, steel • United States – – – – – – – New England- oldest in U.S., textiles Middle Atlantic- Largest U.S. market Mohawk Valley- steel, food process Pitts- Lake Erie- steel 19th century Western Great Lakes- transpo, steel Southern Cal- 1940s- aircraft SE Ontario- Canada’s most imp., steel • East Asia – Japan • Industrial power in 1950s, 1960s • Became world leader in autos, ships, cameras, stereos, TVs – China • World’s largest supply of lowcost labor, largest consumer market. Explaining and Predicting Where Industries locate • Alfred Weber’s Least Cost Theory of Industrial Location – Set out to predict where factories would choose to locate and grow – Similar to Von Thunen, studied the locations of industrial activities and set up a hypothetical state with several assumptions – Called the Least Cost Theory because it predicted where industries would locate based on the places that would be the lowest cost to them – Industries wanting to locate where transportation costs are minimized must consider two issues: • The distance of transportation to market • Weight of goods being transported Weber’s Model • Assumptions – Transportation cost determined by the weight of the goods being shipped and the distance they are being shipped • The heavier the good and/or the farther the distance = the most expensive to ship – Industries are competitive and aim to minimize their costs and maximize their profits – Markets are in fixed locations – Labor exists only in certain places and is not mobile – Physical geography and politicalcultural landscape are assumed to be uniform across the model’s space • With these assumptions, the location of industry is driven by four factors • • • • Transportation Labor Agglomeration Deglomeration • Critics – Theory does not identify the fact that markets and labor are often mobile and that the labor force varies in age, skill sets, gender, language, etc. – Some transportation costs are not directly proportional to distance Concepts related to Weber’s Model • Weight-Gaining versus Weight-Losing Industries • – Manufacturing processes that take the raw materials and convert them into a product that is lighter than the raw materials that went into making it – Early factories also had to consider their proximity to the raw materials they needed • Also called “material orientation” or “bulkreducing” • These early factors had spatially-variable costs – – costs that changed depending on the factory’s location • A factory using heavy or perishable raw materials in its production might be built as close as possible to its source of raw materials to minimize the cost of transporting the materials into the factory Weight-losing processes • Ex: paper production, copper, steel Weight-gaining processes – Take raw materials and create a heavier final product • When weight-gaining industries locate near the place where the heavier product will be sold called “market oreintation” or “bulk-gaining” – Ex: Beverage bottling industry, fabricated metals U.S. Steel Industry • Two principal inputs (resources) of steel are iron ore and coal • Steel-making is an example of bulkreducing industry – Needs to be located next inputs to minimize transportation costs – Map of “Rust belt” • Centers of Steel Production – Mid-19th century • Concentrated near Pittsburgh, P.A. • Today center for research – Late 19th century • Built around Lake Erie and OH cities • Influenced by new discovery of iron ore in Mesabi Range in Minn. – Early 20th century • Located near Lake Michagan • Closer to Mesabi range – Mid-20th century • Closter to ocean on both coasts • Reflective of Iron ore from other countries – Today • Most in U.S. are closed Concepts related to Weber’s Model • Footloose Industries – Are not restricted in where they can locate because of transportation costs • Some maintain the same cost of transportation and production regardless of where they choose to locate – They industries have spatially fixed costs • costs that remain in same no matter where they choose to locate – Often produce lightweight products of extremely high value • Computer chips Transportation • Inputs and products transported one of four ways – Trucks • Short-distance delivery • Loaded/unloaded quickly • Advantage if driver can reach location in one day – Trains • Often used to ship to destinations that take longer than one day • Take longer to load – Air • Most expensive • Reserved for speedy delievry of small-bulk, high-value packages – Ships • Attractive for very long distances • Slower than land-based transpo • Used for international • • The farther something is transported the cheaper the cost Lots of companies mix the modes of delivery – – – Thanks for containerization Regardless of mode, cost increases each time you change modes of transporation Many companies that use multiple transport mode locate at break-of-bulk points • Location where transfer among modes is possible • Often seaports, airports Concepts related to Weber’s Model • Labor costs and the Substitution principle – The Weber model assumes that the cost of labor is a key factor influencing where industries choose to locate – Included in labor considerations is the availability of industrial capital • Consists of machinery and the money to purchase the tools and workers the factory needs – The substitution principle applies when an industry will move to a place to access lower labor costs, even though transportation costs might increase as a result • In the long run, these companies will save more because of the cheaper labor Labor-Intensive Industries • Definition – One in which the wages and other compensation paid to employees constitute a high percentage of expenses • Labor constitutes an average of 11% of overall manufacturing costs in the U.S. – Labor-intensive industries in the U.S. would have a higher percentage • Average wage paid exceeds $20 an hour in MDCs with benefits – LDCs less than $5 an hour with limited to no benefits • Different that high-wage industry – Labor-intensive measured in percentages – High-wage measured in currency • Examples – Textile and apparel industry • Spinning of fibers and prep work • Weaving or knitting of yarn into fabric • Cutting and sewing of fabric for assembling clothing and other products Concepts related to Weber’s Model • Agglomeration – Occurs when industries clump together in the same geographic space • Alfred Marshall first identified the benefits of agglomeration in industrializing England in the late 19th century – Factories that are in the same area can share costs associated with resources such as electrical lines, roads, pollution control, etc. • Agglomeration economies occur when the positive effects of agglomeration result in lower prices for consumers – Categories of agglomeration economies » » » Localization economies occur when many firms in the same industry benefit from clustering close together Urbanization economies occur when large populations in urban areas benefit from clustering together because they get to share infrastructural elements Ex: power lines and transport system Concepts related to Weber’s Model • High-Tech Corridor and Technopoles – A high-tech corridor is a place where technology and computer industries agglomerate – A technopole is another name for a region of high-tech agglomeration, formed by similar high-tech industries seeking to locate in a shared area so that they can benefit from shared resources • Like sharing a highly-trained workforce, and utilizing similar support businesses – Ex: computer repair shops, electrical wiring services Concept’s related to Weber’s Model • Backwash Effects – Negative consequences of agglomeration that can occur when other areas suffer out-migration (brain-drain) of talented people who are moving to a technopole or other “hot spot” of industry agglomeration • Locational Interdependence – The theory that industries choose their locations based on where their competitors are located – Industries want to maximize their dominance of the market, so they are influenced by the competition. • Ex: Gas stations – Multiple gas stations at highway exit because one would not be enough to service needs Concepts related to Weber’s Theory • Deglomeration – “unclumping” of factories because of the negative effects and higher costs associated with industrial overcrowding – Often occurs when a agglomerated region becomes too clustered, too crowded • Or when such agglomeration negatively affects the industries such as pollution, traffic congestion, or strained resources and labor