Chapter Seven-Joint and By-product Costing

advertisement

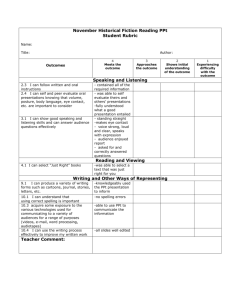

COST MANAGEMENT Don R. Hansen Maryanne M. Mowen PPT 7 -1 Chapter Seven Joint Product and By-Product Costing PPT 7 -2 Learning Objectives Identify the characteristics of the joint production process. Allocate joint product costs according to benefitsreceived approaches and the relative market value approaches. Describe methods of accounting for by-products. PPT 7 -3 Learning Objectives (continued) Explain why joint cost allocations may be misleading in management decision making. Discuss why joint production is seldom found in service industries. PPT 7 -4 Joint Production Process Pork Meat Raw Material: Hog Processing Split-Off Point Hides PPT 7 -5 Independent Multiple-Product Production Processing Mustang Processing Taurus Raw Material: Steel PPT 7 -6 Joint Production Process Joint products are two or more products produced simultaneously by the same process up to a “splitoff” point. The split-off point is the point at which the joint products become separate and identifiable. Separable costs are easily traced to individual products and offer no particular problem. PPT 7 -7 Joint Production Costs (Manufacturing perfume) Joint Costs Separable Costs Processing $100,000 Oil Processing $400,000 Processing $300,000 (Flower Oil) Charm: 10,000 ounces @ $40 per ounce Wild Scent: 20,000 ounces @ $10 per ounce Wild Flower: 50,000 ounces @ $1 per ounce PPT 7 -8 By-Product Costs Characteristics By-product resulting from scrap, trimmings, and so forth, of the main products in essentially nonjoint-product types of undertakings (e.g., fabric trimmings from clothing pieces). Scrap and other residue from essentially jointproduct types of processes (e.g., fat trimmed from beef carcasses). A minor joint product situation (fruit skins and PPT 7 -9 trimmings used as animal feed). By-Products The distinction between joint and by-products rests solely on the relative importance of their sales value. A by-product is a secondary product recovered in the course of manufacturing a primary product. PPT 7 -10 Examples of Joint Products and By-Products Industry Joint Products and By-products Agriculture and Food Industries Flour milling Patent flour, clear flour, middlings, bran, and wheatgem Extractive Industries Copper mining Copper, gold, silver, and other metals Chemical Industries Soap making Soap and glycerine Manufacturing Cement Concrete pipe and aggregate PPT 7 -11 Accounting For Joint Product Costs Methods Benefits-Received Approaches Physical Units Method Weighted Average Method Allocation Based on Relative Market Value Sales-Value-at-Split-Off-Method Net Realizable Value Method PPT 7 -12 Joint Costs Example An Example: Suppose that a sawmill processes logs into four grades of lumber totaling 3,000,000 board feet as follows. Board Feet Weight Factor Price at Split-Off (per 1,000 ft.) 1 450,000 1.30 $300 2 1,200,000 1.10 200 3 600,000 1.00 121 4 750,000 .50 70 Total 3,000,000 ======= Grades Total joint cost is $186,000 PPT 7 -13 The Physical Units Method Board Feet % of Units Joint Cost Allocation 1 450,000 .15 $ 27,900 2 1,200,000 .40 74,400 3 600,000 .20 37,200 4 750,000 .25 46,500 Total 3,000,000 ======= Grades $186,000 ======= PPT 7 -14 Weighted Average Method Grades 1 2 3 4 Totals * Rounding Board Feet 450,000 1,200,000 600,000 750,000 3,000,000 ======= Weight Factor 1.30 1.10 1.00 .50 Weighted # of Board Feet 585,000 1,320,000 600,000 375,000 2,880,000 ======= Percent .2031 .4583 .2083 .1302 100.00 ===== Allocated Joint Cost $ 37,776 85,244 38,744 24,217 *$186,000 ======= Error Grades with higher weights require more cost to obtain the required finish and quality appearance. PPT 7 -15 Sales-Value-At-Split-off Method Grades 1 2 3 4 Totals Board Feet 450,000 1,200,000 600,000 750,000 3,000,000 ======= Price at Split-Off $300 200 121 70 Sales Value at Split-off $135,000 240,000 72,600 52,500 $500,100 ====== Percent .2699 .4799 .1452 .1050 100.00 ===== Allocated Joint Cost $ 50.201 89,261 27,007 19,530 *$186,000 ====== *Rounding Error PPT 7 -16 Net Realizable Value Method An Example: Suppose that a company manufactures two products, Alpha and Beta, from a joint process. One production run costs $5,750 and results in 1,000 gallons of Alpha and 3,000 gallons of Beta. Neither product is salable at split-off, but must be further processed . The separable costs for Alpha is $1 per gallon and for Beta is $2 per gallon. The eventual market price for Alpha is $5 and for Beta $4. Alpha Beta Market Price $5 4 Further Hypothetical Processing Cost $1 2 Market Price $4 2 Hypothetical Number of Units 1,000 3,000 Market Value $4,000 6,000 $10,000 Allocated Joint Cost $2,300 3,450 $5,750 PPT 7 -17 Constant Gross Margin Percentage Method Using data from the previous example: Revenue [($5 x 1,000) + ($4 x 3,000)] Costs[$5,750 + ($1 x 1,000) + ($2 x 3,000)] Gross profit $17,000 12,750 $ 4,250 100 % 75 25 % Alpha Beta Eventual market value Less: Gross margin @ 25% Cost of goods sold Less: Separable costs $5,000 1,250 $3,750 1,000 $12,000 3,000 $ 9,000 6,000 Allocated joint costs $2,750 ===== $ 3,000 ===== PPT 7 -18 Sales-To-Production-Ratio Method Assume that $1,000,000 of joint cost was allocated to five products based on the sales-toproduction ratio. Note that under this method, less cost is assigned to slower moving goods like Product C, which accounted for 25% of production by only 15% of sales. A good like Product B, which accounted for just 15% of production but 20% of sales, receives relatively more joint cost. The end result is that relatively higher production cost is matched against current revenues, and the company claims lower net income for tax purposes. Product A B C D E %of Total Sales 10 20 15 40 15 100 === % of Production 10 15 25 30 20 100 === Sales-to-Production Ratio Percent 1.0000 19.9338 1.3333 26.5778 0 .6000 11.9603 1.3333 26.5778 0.7500 14.9504 5.0166 *100.000 ===== ====== Cost Assigned Sales/Prod. $ 199,338 265,778 119,603 265,778 149,504 $1,000,001 ======== *Rounding error PPT 7 -19 Accounting for By-Product Costs Given for a main product and a by-product: Total manufacturing costs of main product and by-product $22,000 Total sales of main product 25,000 Estimated net realizable value of by-product produced 2,000 Beginning inventories (including ending inventory of by-product) None Ending inventory of main product is 25% of production volume Ending inventory of by-product is 10% of production volume PPT 7 -20 Accounting for By-Product Costs (continued) Sales of main product Cost of goods sold: Total manufacturing costs Deduct net revenue of byproduct (90% x $2,000) Net manufacturing costs Deduct main product inventory (25% x 20,200) Deduct byproduct inventory (10% x $2,000) Gross margin $25,000 $22,000 1,800 $20,200 5,050 200 14,950 $10,050 ====== By-product revenue is treated as a reduction of main product manufacturing costs. PPT 7 -21 Accounting for By-Product Costs (continued) Sales of main product Add net revenue of byproduct (90% x $2,000) Total Sales Cost of goods sold: Total manufacturing costs Deduct main product inventory (25% x 22,000) Deduct byproduct inventory (10% x $2,000) Gross margin $25,000 1,800 $26,800 $22,000 5,500 200 16,300 $10,500 ====== By-product revenue is treated as a separate revenue item. PPT 7 -22 Effect of Joint Product Costs on Cost Control and Decision Making It is important to understand when the use of allocated joint product costs may be misleading. In making decisions relative to jointly produced articles, it must be remembered that the products are necessarily produced jointly. Some areas that can be affected by joint cost allocations are: Output decisions Further processing of joint products Pricing jointly produced products PPT 7 -23 End of Chapter 7 PPT 7 -24