Chemical Strengthening of LAS Glass

advertisement

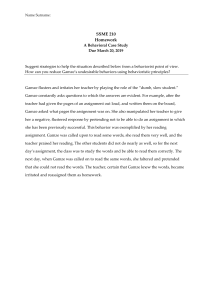

Chemical Strengthening of LAS Glass-Ceramics for Thinner and Stronger Automobile Glasses Gamze KARAKEDI, Ali Coskun ATLAS and Emrah DOLEKCEKİC Department of Materials Science and Engineering, Anadolu University, Eskisehir, Turkey Abstract: Automotive industry is a very strong sector in terms of internal volume, employment, and economy and it affects many sectors. However, atmospheric pollutant emission and the amount of carbon dioxide gas increase due to the increasing number of automobiles; hence, this leads to problems like the greenhouse effect and the climate change. Furthermore, due to the reduction of fossil fuels, automobile producers are in search of automobile design working on different energy sources. Electric vehicles are the most preferred in alternative energy applications because of their eco-friendly behaviors and economical benefits. It is known that the weight of electric automobiles should be as less as possible comparing with commercial fuel oil cars due to the necessity of less energy consumption. For that reason, chemical strengthening methods can be applied to produce more durable and slimmer automobile glasses. In this study, Li2O-Al2O3-SiO2 (LAS) glass- ceramics were used for chemical strengthening process, because, they are usually three times more stronger than commercially available soda-lime-silicate glasses. Chemically strengthened lithium alumina silicate glass-ceramics were characterized by scanning electron microscopy (SEM), four point bending and microhardness tests. Four point bending test results revealed that chemically strengthened LAS glass- ceramics have nearly 4 times higher strength values then commercially available automobile glasses. Keywords: Chemical strengthening, Lithium Alumino Silicate Glass- Ceramics, Automobile glasses