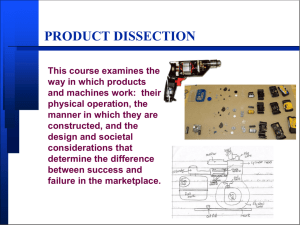

ME240/107S: Product Dissection

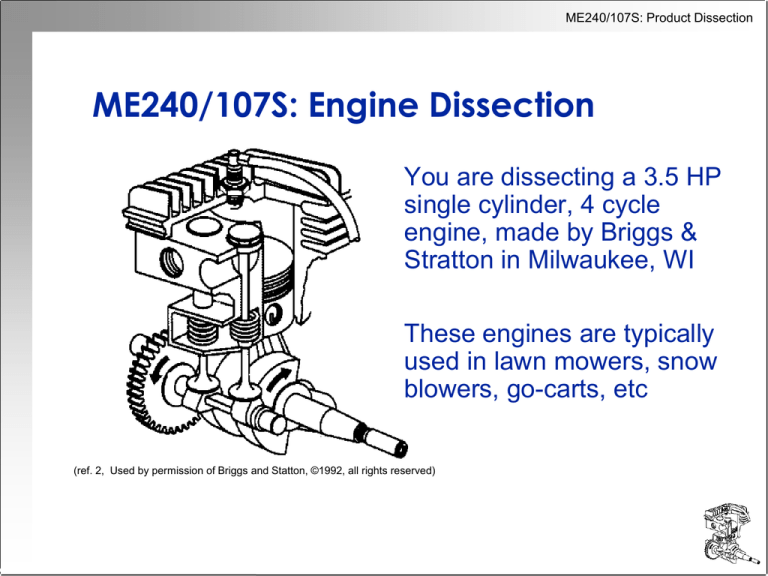

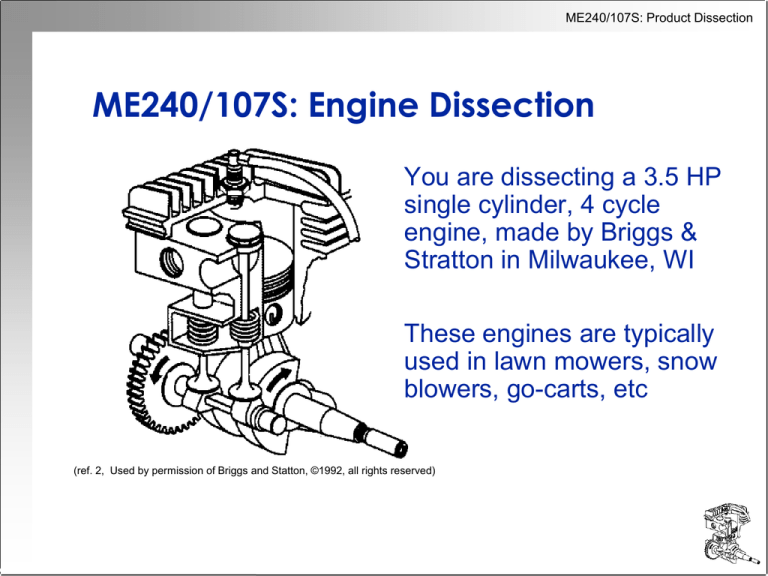

ME240/107S: Engine Dissection

You are dissecting a 3.5 HP

single cylinder, 4 cycle

engine, made by Briggs &

Stratton in Milwaukee, WI

These engines are typically

used in lawn mowers, snow

blowers, go-carts, etc

(ref. 2, Used by permission of Briggs and Statton, ©1992, all rights reserved)

ME240/107S: Product Dissection

Lecture 2

Carburetor

Ignition System

Drivetrain Components

ME240/107S: Product Dissection

Session 1: Carburetor and Ignition

In small groups, discuss your answers to the

following questions from Session 1

Carburetor:

What

are the components of the Pulsa-Jet

Carburetor and how do they work?

How

many jets are used? What is their function?

ME240/107S: Product Dissection

Session 1: Carburetor and Ignition

Ignition:

What

is the purpose of the starter clutch?

Why

is the flywheel comprised of different

materials? What are those materials?

How

does the ignition system work?

How

is ignition timing achieved in the engine?

ME240/107S: Product Dissection

Carburetor

Purpose of the carburetor is to produce a

mixture of fuel and air on which the engine

can operate

Uses a venturi nozzle to

reduce air pressure in

the carburetor to create

suction to “pull” fuel into air

ME240/107S: Product Dissection

Pulsa-Jet Carburetor

Incorporates a diaphragm type fuel pump

and a constant level fuel chamber

ME240/107S: Product Dissection

Pulsa-Jet Carburetor Operation

Intake stroke of piston

creates a vacuum in

carburetor elbow

Pulls cap A and pump

diaphragm B inward and

compresses spring

Vacuum thus created on

“cover side” of diaphragm

pulls fuel up suction pipe S

into intake valve D

ME240/107S: Product Dissection

Pulsa-Jet Carburetor Operation

When engine intake stroke

is complete, spring C

pushes plunger A outward

Gasoline in pocket above

diaphragm to close inlet

valve D and open

discharge valve E

Fuel is then pumped into

fuel cup F

ME240/107S: Product Dissection

Pulsa-Jet Carburetor Operation

Venturi in carburetor is

connected to intake pipe

I which draws gasoline

from fuel cup F

Process is repeated on

the next stroke, keeping

the fuel cup full

Since fuel cup level is

constant, engine gets

constant air-fuel ratio

ME240/107S: Product Dissection

Ignition System

Consists of:

Spark

plug

Armature

Coil

(primary and

secondary)

Flywheel

Magnet

ME240/107S: Product Dissection

Ignition System - Electric Circuit

Uses a changing

magnetic field to

generate current in

primary and

secondary circuits

ME240/107S: Product Dissection

Ignition System - Magnetic Flux

As magnet approaches,

induces magnetic flux in

armature

Breaker points close

and current dissipates

through primary circuit

ME240/107S: Product Dissection

Ignition System - Spark Fires

After magnet rotates past

armature flux reverses

direction, and the breaker

points open

Change in magnetic flux

produces 170 volts in

primary circuit

Induces 10,000 volts in

secondary circuit, firing

spark plug

ME240/107S: Product Dissection

Ignition System - Breaker Point

Crankshaft rotation

causes mechanical

actuation of breaker

ME240/107S: Product Dissection

Ignition System - Magneto System

In Magnetron ignition

system, magnetic flux

induced by flywheel

magnet also actuates

primary circuit and

spark timing

Capacitor helps

regulate current (i.e.,

serves as condenser)

ME240/107S: Product Dissection

The Drivetrain

As a group, brainstorm as many drivetrain

components as you can. You have 3 min.

ME240/107S: Product Dissection

Drivetrain

Provide power via

rotating crankshaft

ME240/107S: Product Dissection

Drivetrain: Piston-Rod Assembly

Piston is connected

to the crankshaft by

the connecting rod

Vertical motion of

piston rotates the

crankshaft

What is purpose of

compression rings?

ME240/107S: Product Dissection

Drivetrain: Valves

Valves regulate air-fuel

flow mixture into and out

of piston cylinder

ME240/107S: Product Dissection

Drivetrain: L-Valve Actuation

Camshaft drives

actuation and

timing of intake

and exhaust

valves in L-head

configuration

ME240/107S: Product Dissection

Drivetrain: Valve Actuation

In overhead or I-head,

camshaft actuates a

tappet (lifter) which

forces a push rod

upward, causing the

rocker arm to rotate to

actuate the valves

What is the purpose

of the valve spring?

Rocker arm

Push rod

Tappet

ME240/107S: Product Dissection

4 Stroke Cycle

1

Intake Valve

Intake

Manifold

Cylinder

2

Exhaust Valve

Exhaust

Manifold

3

4

Spark

Plug

Piston

Connecting

Rod

Intake Stroke

Intake valve opens,

admitting fuel and air.

Exhaust valve closed

for most of stroke

Crank

Crankcase

Compression Stroke

Both valves closed,

Fuel/air mixture is

compressed by rising

piston. Spark ignites

mixture near end of

stroke.

Power Stroke

Fuel-air mixture burns,

increasing temperature

and pressure, expansion

of combustion gases

drives piston down. Both

valves closed - exhaust

valve opens near end

of stroke

Exhaust Stroke

Exhaust valve open,

exhaust products are

displaced from cylinder.

Intake valve opens

near end of stroke.

ME240/107S: Product Dissection

Parts of an

IC Engine

Name as many

parts as you can

Your name:_________________

CROSS SECTION OF OVERHEAD VALVE FOUR CYCLE SI ENGINE