ME240/107S: Product Dissection

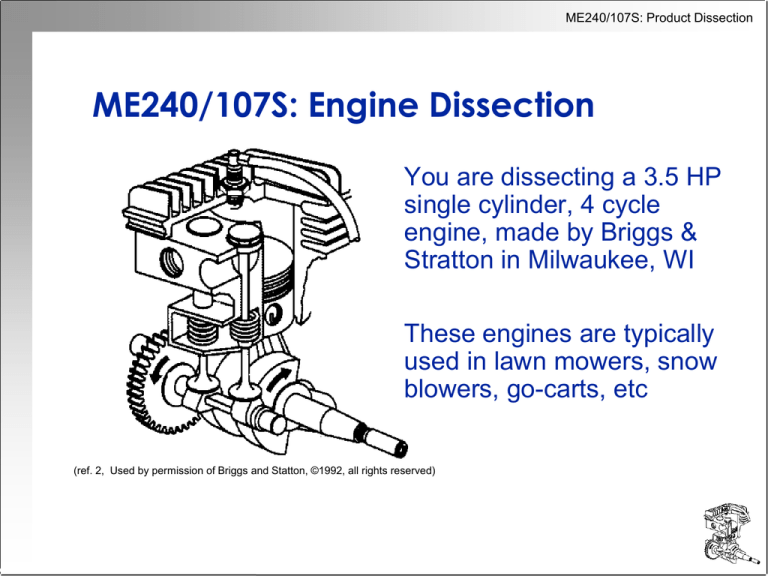

ME240/107S: Engine Dissection

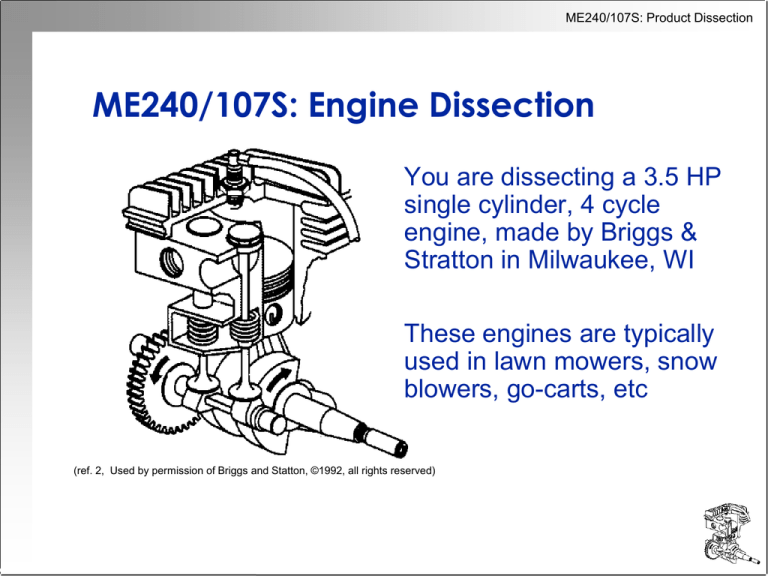

You are dissecting a 3.5 HP

single cylinder, 4 cycle

engine, made by Briggs &

Stratton in Milwaukee, WI

These engines are typically

used in lawn mowers, snow

blowers, go-carts, etc

(ref. 2, Used by permission of Briggs and Statton, ©1992, all rights reserved)

ME240/107S: Product Dissection

Lecture 3

Material Considerations

Why Internal Combustion?

Engine Labeling Diagram

ME240/107S: Product Dissection

Session 2: Engine Block and Drivetrain

What materials are used in the camshaft?

How are the cams fastened to the shaft?

What material is used for the crankshaft?

What manufacturing processes were used

for the crankshaft, camshaft, connecting

rod, wrist pin, and piston?

What type of lubrication system does your

engine have and how does it work? Which

components receive lubrication?

ME240/107S: Product Dissection

Crankshaft

Originally steel forged;

however, large stiff

crankshafts with

relatively low stresses

allowed cast iron to be

substituted as a

means to reduce cost

How is crankshaft

supported?

ME240/107S: Product Dissection

Piston Assembly

Piston: aluminum, cast steel

or cast iron

Wrist pin: machined steel

Connecting rod: forged-steel

or cast iron

ME240/107S: Product Dissection

Cylinder Head and Crankcase

Crankcase and cylinder

block are usually cast

iron; however, some

have been assembled

from welded steel plate

Crankcase and cylinder

are usually integral for

greater rigidity

How is cylinder

head made?

Cylinder block

Crank case

ME240/107S: Product Dissection

Cylinders

How are cylinders fabricated?

Gray

cast iron with cylinder bores machined to

meet tolerance

Why must a new engine be “broken in”?

Cast

iron forms a hard glazed surface when

subject to sliding friction

When first assembled, slow speeds and light

loads should be used to facilitate forming this

protective coating to give long engine life

ME240/107S: Product Dissection

Camshaft and Cams

Camshaft and cams are

usually made from steel

In your Briggs & Stratton

engine, how is camshaft

made? How are cams

fastened?

What does the little

metal flapper do?

ME240/107S: Product Dissection

Valves

Intake valve: a

chromium-nickel

alloy

Exhaust valve: a

silicon-chrome alloy

since it operates at

higher temperatures

(about 1200oF)

ME240/107S: Product Dissection

Engine Temperature Profiles

What two

purposes

does engine

lubrication

serve?

minimize

friction

dissipate

heat

ME240/107S: Product Dissection

How does your engine lubrication

system work?

An oil pan seals

the engine block,

providing a

reservoir for

lubricating oil for

most drivetrain

components

Dip stick

Oil gallery

(for piston)

Oil gallery

Oil pan

How is oil pan

fabricated?

ME240/107S: Product Dissection

Automotive Fuel Needs

x1.1

x2.2

x2.5

After combustion and friction losses are considered, only

about 1/6 of energy available in gasoline is actually used

ME240/107S: Product Dissection

Minimizing

Losses

ME240/107S: Product Dissection

Streamlining to Reduce Air Drag

ME240/107S: Product Dissection

Why Internal Combustion?

IC engines were thought to have a bleak

future when first invented

“You can’t get people to sit over an explosion”

“The automobile industry will surely

burgeon…but this motor will not be a factor.”

- Col. Albert A. Pope, largest

automobile manufacturer at the

turn of the century

ME240/107S: Product Dissection

Why Internal Combustion?

Each group will be assigned either a steam,

electric, or internal combustion engine.

Within your group, discuss the pros/cons of

your particular type of engine based on

what you know and read in “Why IC?” article

At the end of your discussion, be prepared

to share your results with the class

ME240/107S: Product Dissection

History of IC Engines

1860 Lenoir’s

engine (a converted

steam engine)

combusted natural

gas in a double

acting piston, using

electric ignition

ME240/107S: Product Dissection

Stanley Steamer

ME240/107S: Product Dissection

History - continued

1876 Nikolaus Otto patented the 4 cycle engine;

it used gaseous fuel

1882 Gottlieb Daimler, an engineer for Daimler,

left to work on his own engine. His 1889 twin

cylinder V was the first engine to be produced in

quantities. It used liquid fuel and Venturi type

carburetor, engine was named “Mercedes” after

the daughter of his major distributor

1893 Rudolf Diesel built successful IC engine

which was 26% efficient (double the efficiency of

any other engine of its time)

ME240/107S: Product Dissection

Complementary Technologies for

IC Engine-powered Automobiles

Pneumatic tires (1888, Dunlop)

Cheap liquid fuels (Oil industry born in PA 1859)

Venturi effect carburetor (1892, Willi Maybach)

Variable mechanical transmission (primitive type

by Levassor, 1891)

Electric starter (1912 by Kettering of Cadillac)

The real end to electric cars? http://usat.ly/wRmS5K

ME240/107S: Product Dissection

Parts of an

IC Engine

Name as many

parts as you can

Your name:_________________

CROSS SECTION OF OVERHEAD VALVE FOUR CYCLE SI ENGINE