i-DMSS for Bus Rental in Seoul, Korea

advertisement

i-DMSS for Bus Rental in Seoul, Korea

Katta G. Murty

Dept. IOE, U. of Michigan

Ann Arbor, MI-48109-2117, USA

e-mail: murty@umich.edu

and

Woo-Je Kim

Dept. of IISE, Seoul National University of Technology

172 Gongneung 2-dong, Nowon-gu, Seoul 139-743, South Korea

e-mail: wjkim@snut.ac.kr

Work done for Arirang in Seoul, South Korea,

which rents buses (with drivers) to groups

n = up to 100 customer requests daily

Each request called job specifies

Start location pi

Start time t

i

End location q

_

End time ti

i

Group size

D = (dij) is distance data matrix for day

Each job involves travel (possibly with stops),

driver has to be available to group continuously

Two bus types:

45 seat (20 available, for large groups)

15 seat (5 available, for small group)

Stationed at two separate depots

Company can also borrow buses from other vendors

Duration of job = end time - start time

Varies from half hour to 20 hours

For 75% of jobs, duration is less than five hours

Job Number: Serially in increasing order of start

Work-sequence: Sequence of jobs handled by a bus in a day

Necessary condition for i1, ... ir to be a work- sequence:

_

t {s+1} - ts > driving time from qs to p{s+1} for s = 1 to r-1

In this work sequence, the driver of bus from qs to p{s+1}

for s = 1 to r called empty load drives

_

Duration of this work-sequence: (depends on depot of bus) = tr - t1 + (driving

time from depot to p1) + (driving time from qr to depot)

Drivers prefer long duration work-sequences (more money). But company has

safety limit = 12 hours.

But 10% jobs are long > 11 hour duration. They are OK, because they have

intermediate stops when driver can rest. Only long duration work-sequences with

continuous driving (fatigue causing) problematic

Decisions to be made:

Partition trips into work-sequences,

each for a bus

Allocate buses from two depots, (and

outside vendors if necessary) to worksequences

Objectives to Optimize

min OBJ1 = number of buses to handle

jobs = number work-sequences into

which jobs partitioned

min OBJ2 = total cost of empty load

driving

Keep OBJ3 = % of long duration worksequences below 50 as far as possible

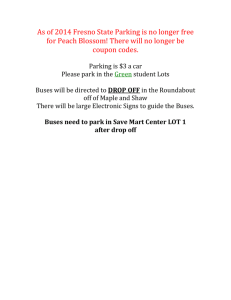

Representation Using Network G

Each trip a node

N = set of nodes

Include arc (i, j) if bus

can handle trip j after

completing trip i

A = set of arcs

Leave long duration

trips as isolated nodes

G = (N, A) acyclic

network (no directed

cycles)

Each work-sequence is a

chain in G, and each

chain (including single

node chains) in G can

be a work-sequence

5

8

2

4

1

0

7

1

3

6

9

1

1

How to minimize OBJ1?

Can be

minimized by

finding a min

chain cover for

nodes of G

(i.e., smallest

number of chains

containing all

nodes)

This problem

transformed into

a max bipartite

matching

problem, can be

solved very

efficiently

How to minimize OBJ2?

OBJ2 = OBJ2.1

+ OBJ2.2,

OBJ2.1 is cost

of empty load

drives between

consecutive

jobs in worksequence,

OBJ2.2 is

empty load

drives from, to,

depot

i1

i2

i3

..

ir

OBJ2.1 depends only on how jobs

portioned into work-sequences for buses

OBJ2.2 depends on from which source

(depot 1, 2, outside vendor) buses

allocated to work-sequences

We minimize OBJ2.1, 2.2 in separate

stages

How to minimize OBJ1, OBJ2.1

simultaneously?

Find a min

cost max

matching in

bipartite

network, and

use it to form

worksequences

Can be solved

efficiently

using

assignment

algorithm

How to Handle OBJ3?

OBJ3 makes problem hard. Even simpler problem of forming

work-sequences with no long duration work sequences has

been proved hard. Handle OBJ3 heuristically, manually

(interactively)

Removing longest arc, reapplying algorithm usually reduces %

of long duration work sequences, while increasing OBJ1 only

slightly

Breaking some longest duration multi-trip work-sequences into

two of reasonable durations, exchanging trips at beginning or

end of some long duration ones to others, always yields good

set, to implement

How to Minimize OBJ 2.2

Let WS1,..., WSs be work-sequences in final solution

set

Let Depot 1, 2, OV (Outside Vendor) be sources of

buses

Knowing WSt, we can easily calculate value of OBJ

2.2 (cost of driving from source to starting location of

first trip + from ending location of last trip back to

source) for allocating bus from source to WSt, and

model this problem as a 3 x s transportation

problem

Strategy for the problem

Our strategy is a 2-stage hierarchical process

Stage 1: Select work sequences to implement, to min

OBJ1, OBJ 2.1 simultaneously, by solving min cost max

matching in bipartite network

Modify work sequences obtained to satisfy OBJ 3

interactively by heuristic techniques

Stage 2: Allocate buses from sources to selected worksequences to min OBJ 2.2 by solving transportation model

How to Handle 2 Bus Sizes?

5 small 15 seat buses

On days when more small buses needed, much cheaper to

use one of company's large 45 seat buses than renting small

bus

Use following procedure:

1. Consider only small group jobs. Use algorithm to allocate

small buses to these, up to 5 available

2. If any small group jobs unallocated, combine them with set

of large group jobs and use algorithm to allocate large buses

to this set

Results

Previously decisions made manually, took two

people

Using DSS, solution time reduced to a few manhours each day

OBJ1 reduced by 15% from manual approach

OBJ2 reduced by 10% from manual approach