machine intelligence_MAY09

advertisement

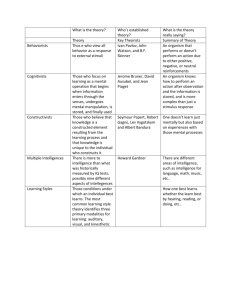

Research and Innovation Machine Intelligence: An Investigation in the Application of Hierarchical Temporal Memory L. Salemi, Professor Centre for Construction and Engineering Technologies May 2009 Introduction Project was approved in Oct. 2008 • Seed Funding - $6,250 • OCE Connections Grant - $3,000 Student participation from 3 programs • T146 Electro-Mechanical Engineering Technician • T147 Computer Systems Technology • T121 Mechanical Engineering Technology - Design Introduction – The Team Research Assistants • Clayton Wozney • Steven Irwin • Michael Joyette • Olek Kushnarenko • Scott Vannan • Terence D'Cunha • Avinash Singh • Intiaz Abdulla Section T121 T146 T146 T146 T146 T147 T147 T147 Status Paid Researcher Course Credit Course Credit Volunteer Volunteer Course Credit Course Credit Course Credit • Volunteers - Albert So, Bruno D’Agostino Introduction – Industry Involvement Company Status Industrial Technical Services – Reynold Ramdial – Amit Setti In Kind Sponsor • Grace Instrumentation & Controls – Terry Grace Equipment Donation • Hoskin Scientific – Marc DeGrace Technical Advisor • Hatch Engineering – Dennis Phair Technical Advisor Equipment Donation • ISA Toronto Section – Currie Gardner Presented at the ISA Technical Conference during the Ontario Process and Automation • Technical Support Show April 2009 Introduction – The Plan Phase 1: Oct – Dec 08 C. Wozney Paid Researcher Investigate HTM Technology Create Workspace Rm. C504A Wozney to manage Phase 2 6 - Student Volunteers (T146) Students to Work for Course credit Phase 2: Jan – May 08 Collect Data Plan B Build the Infrastructure Simulate Remote Site Control Objective Apply Intelligence to Building Automation Applications Use one of the classrooms to collect data • • • • HVAC (Heating, Ventilation, and Air Conditioning) Lighting (Occupancy based) Security (Access control, intrusion) Security Cameras Incorporate intelligence to • • • Turn off the lights when no one is in the room Lower the temperature Monitor room occupancy Research Question How can we make a machine intelligent? But first, what is intelligence? • Human Intelligence • Machine Intelligence • Artificial Intelligence • Military Intelligence There is no universal definition Research – The Challenge Intelligence Test: Which one is flat? Research Question Answer: All of the above are flat Does intelligence lie in the senses of the beholder? Yes/No? • • • Our 5 primary sensors provide an abundance of data Our intelligence forms the conclusion (BELIEF) Where is this “intelligence” located and how can we make a machine do it? Research – The Answer Hierarchal Temporal Memory (HTM) • Developed by Jeff Hawkins founder of Numenta and inventor of palm pilot & treo • HTM is modeled after the neocortex • Data is fed to neuron-like networks that learn to recognize patterns and sequences that change over time • When presented with “new” data the HTM is good at predicting what it is • www.numenta.com Book: On Intelligence Research – The Technology • NuPIC (Numenta Platform for Intelligent Computing) • Vision4 Demo program was designed using HTM networks What’s this? Research – The Technology Vision4 Demo program was trained to recognize 4 different images • Sail Boat • Rubber Duck • Cell Phone • Cow Research – The Technology Its not perfect but neither are we. Sailboat ??? Research – The Technology • More detail provides better recognition It’s a duck Research – The Technology • HTM is capable of recognizing several variations Cow in the background How far away are we? • Not a question of if, but when! • Next 400 years? • Only 400 years have passed since we thought the earth was flat. "I visualize a time when we will be to robots what dogs are to humans. And I'm rooting for the machines." - Claude Shannon (1916 - 2001) Industry Problem Phase 2 - How to apply HTM intelligence to Building Automation applications Identifying an industry problem was difficult • Many “smart” systems already out there • HTM was beyond our scope – now what? • HTM would be hard to sell to industry partners without something to demo Leo’s Problem • Engage students and comply with course outlines (course credit for research work) • Build something that we could demonstrate to attract industry partners • No Clayton – No HTM • Go with Plan B Methodology – Plan B Plan B – Make sure Plan A works Build the infrastructure to collect real time data in room C504A • Simulate something that is used in industry (remote water pumping station) • Be able to monitor and control the site remotely via the web • Use current technologies plus add some extra’s – SCADA (Supervisory Control And Data Acquisition) – Security Alarm and Video Surveillance – Process Cameras for operators – Full network integration for each subsystem • Incorporate intelligence between all of the subsystems Results Remote monitoring & control of pumping station – Operator has full control of station (typical) – Process cameras allow operators to view the station as if they were present – Surveillance Alarm & Cameras connected via the web and VOIP system (24/7 monitoring station) – SCADA system used to the control process – More features to be added Infrastructure Testing Lab VOIP Operator Terminals Security System REMOTE SITE Pumping Station SCADA Control System Surveillance Cameras Process Cameras Lessons Learned Benefits gained • Excellent learning experience for students and professor • Infrastructure Testing Lab – a place for us to work and others to utilize • Opportunity to learn new technologies and add to curriculum • Interdivisional co-operation • Industry Partners Lesson Learned Bumps along the way • Hard to convince some of the course coordinators to let students do this for a course credit (T147 was the exception) • Uncertainty of the use of room 504A makes it difficult to plan future projects Future Research • Full integration of sub-systems using an OPC data manager • Train the HTM using the remote site data • Work with Video Analytics • Design and build sensors that are HTM-ready • Attracted an industry sponsor who is interested in using solar power in a remote site application Questions Thank you and Acknowledgements Meadow Larkins and the ARI team The student research team Reynold Ramdial and Amit Setti from Industrial Technical Services Members of the technical advisory committee Jeff Litwin for supporting our efforts ISA Toronto for allowing us to present at their technical conference in April