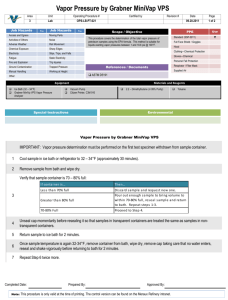

OPS-LB-PT-020 Vapor Pressure by Grabner CCA

advertisement

Vapor Pressure by Grabner CCA-VPS Area 3 Job Hazards Unit Lab Yes Operating Procedure # OPS-LB-PT-020 Job Hazards Access and Egress Moving Parts Activities of Others Noise Adverse Weather Rail Movement Chemical Exposure Sharp Edges Electricity Slips, Trips, and Falls Fatigue Static Electricity Fire and Explosion Trip Injuries Ground Contamination Trapped Pressure Manual Handling Working at Height Certified by Yes Revision # Scope / Objective Page 1 of 2 PPE Standard (SSP-0011) This procedure covers the determination of the total vapor pressure of petroleum samples using the EPA formula. This method is suitable for liquids exerting a vapor pressure between 1 and 18.6 psi @ 100°F. Full Face Shield / Goggles Hood Clothing—Chemical Protection Gloves—Chemical Personal Fall Protection Respirator / Filter Mask References / Documents Supplied Air ASTM D 5191 Other: Equipment Ice Bath (32 – 34°F) Grabner CCA-VPS Vapor Pressure Analyzer Date 10.11.2011 Materials and Reagents Vacuum Pump Citizen Printer (CMB-910) Special Instructions 2.2 – Dimethylbutane (≥ 99% purity) Toluene Environmental Vapor Pressure by Grabner CCA-VPS IMPORTANT: Vapor pressure determination must be performed on the first test specimen withdrawn from sample container. 1 Cool sample in ice bath to 32-34°F (approximately 30 minutes). 2 Remove sample from bath and wipe dry. Verify that sample container is 70-80% full: If container is… Then… Less than 70% full Discard sample and request new one. Greater than 80% full Pour out enough sample to bring volume to within 70-80% full, reseal sample and return to bath. Repeat Steps 1-3. 70-80% full Proceed to Step 4. 3 4 Unseal cap momentarily before resealing it so that samples in transparent containers are treated the same as samples in nontransparent containers. 5 Return sample to ice bath for 2 minutes. 6 Once sample temperature is again 32-34°F, remove container from bath, wipe dry, remove cap taking care that no water enters, reseal and shake vigorously before returning to bath for 2 minutes. 7 Repeat Step 6 twice more. 8 Insert adapter end(s) of sampling tube(s) into sample port(s) (on right side of instrument). Completed Date: Note: Prepared By: Approved By: This procedure is only valid at the time of printing. The control version can be found on the Meraux Refinery intranet. Use Y Vapor Pressure by Grabner CCA-VPS Continued Area 3 Unit Lab Operating Procedure # OPS-LB-PT-020 Certified by Revision # Date 10.11.2011 Page 2 of 2 Vapor Pressure by Grabner CCA-VPS Continued 9 Unscrew knurled nut to remove waste reservoir from left side of instrument. 10 Place tubing from vacuum pump over waste port. 11 Ensure vacuum pump has sufficient oil. 12 From starting display, the cursor is on “ * measuring”; press task button. 13 Turn on vacuum pump and observe pressure reading (bottom right of display screen). 14 Ensure pressure drops to 0.03 psi or less. 15 Turn off pump, disconnect tubing and reattach waste reservoir. 16 Input sample information (using arrow keys): a. Move cursor to “number: #.#” – enter sample port # in the first # position. b. The second # position is for the desired number of measurements (ex., “number: 3.2” means the sample in position 3 of the sampler will be measured 2 times). c. To give sample a particular name, shift cursor to “ * name” and press Task. i. The number # after name is the port position on the multi-sampler (1-6) and should be changed for each port position (sample name). ii. To select sample name from list, shift cursor to # position to right side of display and scroll through list using arrow keys; once desired name is located, shift cursor from # position to one of the letters of the name and press “Task”. iii. To create a new sample name, place cursor on letters in sample name in the “name:# XXXXXXX” field and use arrow keys to shift through various numbers and letters of the alphabet. (Holding down RUN together with ↑ or ↓ key allows scrolling through alphabet in steps of 10 letters at a time.) iv. Continue adding sample names and updating sampler position until all sample names have been entered. 17 Immerse sampling tube(s) into sample(s) ensuring order corresponds to sample info entered previously. 18 Press RUN button to begin measurement(s). 19 Results are printed automatically as each sample analysis is completed. Completed Date: Note: Prepared By: Approved By: This procedure is only valid at the time of printing. The control version can be found on the Meraux Refinery intranet.