New Product Development_3501

New Product Development

What is product development all about?

“

Product development is the set of activities beginning with the perception of a market opportunity and ending in the production, sale, and delivery of the product”

Ulrich & Eppinger, 2002

Some products…

And their development efforts..

Annual Production volume

Sales lifetime

Sales price

Number of unique parts

Development time

Internal development team

(peak size)

External development team

(peak size)

Development cost

Stanley Tools

Jobmaster

Screwdriver

Rollerblade In-

Line Skate

HP DeskJet

Printer

VW New Beetle

Automobile

Boeing 777

Airplane

Product Development Strategy

Task: Define a well-defined product development process and propose a product development organization that will allow your company to compete effectively over the next decade.

• Is there a standard development process that will work for every company?

• What milestones will be used to divide the overall product development process into phases?

• What role do experts from different functional areas play in the development process?

• Should the development organization be divided into groups corresponding to projects or to development functions?

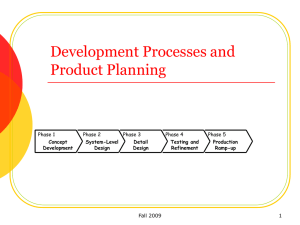

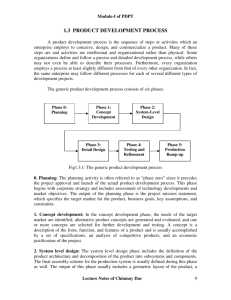

Product Development Process

Phase 0

Planning

Generate mission statement

(target market, business goals, key assumptions and constraints)

Phase 1

Concept

Development

Phase 2

System-level

Design

Phase 3 Phase 4

Detail Design Testing and

Refinement

Phase 5

Production

Ramp-Up

Ulrich and Eppinger 2004

Example

Mission: “design a better hand-held roofing nailer”

Assumptions:

The nailer will use nails (as opposed to adhesives, screws, etc.)

The nailer will be compatible with nail magazines on existing tools

The nailer will nail through roofing singles into wood

The nailer will be handheld.

Product Development Process

Phase 0

Planning

Phase 1

Concept

Development

Identify needs of target market;

Select several product concepts for further development and testing

Phase 2

System-level

Design

Phase 3 Phase 4

Detail Design Testing and

Refinement

Phase 5

Production

Ramp-Up

Ulrich and Eppinger 2004

Example

Needs of target market:

The nailer inserts nails in rapid succession.

The nailer is lightweight.

The nailer has no noticeable nailing delay after starting tool.

Product concepts:

Rotary motor with spring and single impact

Rotary motor with spring and multiple impacts

Linear motor with a moving mass and single impact

Product Development Process

Phase 0

Planning

Phase 1

Concept

Development

Phase 2

System-level

Design

Define product architecture

Decompose product into subsystems and components

Define final assembly scheme

Phase 3 Phase 4

Detail Design Testing and

Refinement

Phase 5

Production

Ramp-Up

Ulrich and Eppinger 2004

Product Development Process

Phase 0

Planning

Phase 1

Concept

Development

Phase 2

System-level

Design

Phase 3 Phase 4

Detail Design Testing and

Refinement

Ulrich and Eppinger 2004 Complete specification of geometry, materials and tolerances of all parts

List of standard parts to be purchased

Detailed drawings

Process plans for fabrication and assembly

Phase 5

Production

Ramp-Up

Product Development Process

Phase 0

Planning

Phase 1

Concept

Development

Phase 2

System-level

Design

Phase 3 Phase 4

Detail Design Testing and

Refinement

Phase 5

Production

Ramp-Up

Building of alpha- and beta- prototypes alpha: same material and geometry

- does it work?

- does it satisfy customer needs?

beta: parts supplied by production process

- tested internally and by customers

- tested for performance and reliability

Product Development Process

Phase 0

Planning

Phase 1

Concept

Development

Phase 2

System-level

Design

Phase 3 Phase 4

Detail Design Testing and

Refinement

Phase 5

Production

Ramp-Up

Small volume production to train workforce and work out any remaining problems.

Finally…

LAUNCH!!

Variations to Product Development Process

• Market pull products

– Market opportunity to technology, e.g. sporting goods, furniture

– Uses generic process

• Technology push products

– Technology to market opportunity, e.g. teflon, gore-tex

– Concept development takes technology as given

• Platform products

– Built around existing platform, e.g. consumer electronics, printers

– Concept development assumes proven technology platform

• Process intensive products

– Product constrained by production process, e.g. semiconductors, chemicals

– Product and process developed from start

• Quick build products

– Rapid modeling and prototyping, e.g. software, cell phones

– Many design-build-test cycles

• Complex systems

– System includes many subsystems and components, e.g. airplanes, jet engines

– System and subsystems developed by many teams working in parallel

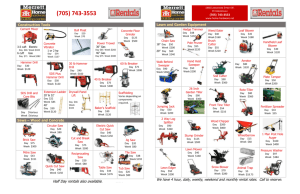

Some products…

And their development efforts..

Annual Production volume

Sales lifetime

Sales price

Number of unique parts

Development time

Internal development team

(peak size)

External development team

(peak size)

Development cost

Stanley Tools

Jobmaster

Screwdriver

Rollerblade In-

Line Skate

HP DeskJet

Printer

VW New Beetle

Automobile

Boeing 777

Airplane

Some development efforts

Stanley Tools

Jobmaster

Screwdriver

Rollerblade In-

Line Skate

Annual Production volume 100,000/year 100,000/year

HP DeskJet

Printer

4M/year

Sales lifetime 40 years 3 years 2 years

Sales price

Number of unique parts

Development time

$3

3

1 year

Internal development team

(peak size)

External development team

(peak size)

Development cost

3 people

3 people

$150,000

$200

35

2 years

5 people

10 people

$750,000

$300

200

1.5 years

100 people

75 people

$50M

VW New Beetle

Automobile

Boeing 777

Airplane

100,000/year

6 years

$17000

10,000

3.5 years

800 people

50/year

30 years

$130M

130,000

4.5 years

6800 people

800 people

$400M

10,000 people

$3B

Food for thought..

• Plot development cost against the other rows and see if there is any correlation. Why or why not?

What drives product development costs?

development cost

3500000000

3000000000

2500000000

2000000000

1500000000

1000000000

500000000

0

-20000

-500000000

0 20000 40000 60000 80000 100000 120000 140000

# parts

What drives product development costs?

development cost

3500000000

3000000000

2500000000

2000000000

1500000000

1000000000

500000000

0

-500000000

0 2000 4000 6000 8000 10000

Internal team size x duration

What drives product development costs?

development cost

3500000000

3000000000

2500000000

2000000000

1500000000

1000000000

500000000

0

-20000

-500000000

0 20000 40000 60000 80000

Total team size x duration

Market issues…

“

Rather than compete with the super jumbo (a 550-seat cruiser by

Airbus), Boeing has decided to concentrate on a smaller, faster

‘sonic cruiser’. So the petty snipping of old has been replaced by a genuine battle of philosophies: on one side is size, on the other speed ”

The Economist, July 2001

Technical issues…

… “ advance fuel cell-vehicles, could have a profound effect on vehicle manufacturing - perhaps setting the stage for the reinvention of the automobile business. One of the biggest hurdles is the development of safe and effective on-board hydrogen storage.

”

L. D. Burns

Vice President of R&D, General Motors

Resource issues…

“AstraZeneca has to rein in some of its most promising drug candidates because of lack of resources to develop them simultaneously ”

Claes Wilhelmsson

Head of R&D, AstraZeneca

Who is Involved in Product Development?

• Marketing

– Mediates interactions between firm and customers

– Identifies product opportunities

– Defines market segments

– Identifies customer needs

– Oversees launch and promotion of product

• Design

– Lead role in defining physical form of product to best meet customer needs

– Includes engineering design and industrial design

• Manufacturing and supply chain

– Designs and operates the supply chain in order to produce the product from procurement to distribution

Characteristics of Successful Product

Development

• Product quality

– How good is the product?

• Product cost

– What is the capital equipment cost and unit production cost?

• Development time

– How quickly did the team complete the effort?

• Development cost

– How much did the firm have to spend to develop the product?

• Development capability

– Are the team and firm better able to develop other products?

Challenges of Product Development

• Trade-offs

– Lightweight vs costly

• Dynamics

– Technologies, customer tastes, competition change environment

• Details

– Screws vs snap fits on enclosure of computer

• Time pressure

– Decisions made quickly and without complete information

• Economics

– Large investment – will it pay off?

• Organizational realities

– Team composition, empowerment, functional allegiance, resources

Design Changes over Time

Quality Function Deployment

• A method to translate customer requirements into engineering specifications

• Aims to get design, engineering and production people involved early on in the process

Quality Function Deployment

Quality Function Deployment (QFD)

Quality Function Deployment (QFD)

Quality Function Deployment (QFD)

Quality Function Deployment (QFD)

Quality Function Deployment (QFD)

Organizational challenges

• How should the product development team operate?

Project-Based Organization

Marketing Engineering Operations

Project Manager Project 1

Project

Managers have more power

“Heavy Weight”

Project Manager Project Manager Project 2

Functional-Based Organization

Marketing manager Engineering Operations manager

Project 1

Project 2

Project 3

Project 1

Project 2

Project 1

Project 2

Project 3

Project 4

Functional managers have more power

Matrix Organization

Marketing manager R&D manager Engineering

Project 1

Project 2

Pros and cons

Functional

Strength

Weakness

Example

Major issue

Matrix Project

Fosters specialization and expertise

Coordination among groups can be slow

Slight variations to custom design

How to integrate different functions to achieve a common goal.

Provides integration and speed benefits

Optimal resource allocation, quick trade-off resolution

Requires more managers and administrators

Difficulty maintaining functional capabilities

Many recently successful projects in automobile, electronics, aero

How to balance functions and projects. How to evaluate project & functional performance.

Start-up companies, dynamic markets, to achieve breakthroughts

How to maintain functional expertise over time

Final Word…

Phase 0

Planning

Phase 1

Concept

Development

Phase 2

System-level

Design

Phase 3 Phase 4

Detail Design Testing and

Refinement

Phase 5

Production

Ramp-Up

Product development is a process and it can be managed!!