Bourdon tube

advertisement

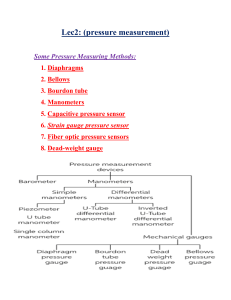

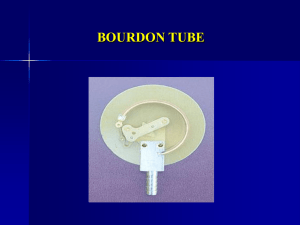

Lecture 2: Pressure Measurements 1 Pressure • Pressure is the force per unit area that a liquid or gas exerts on its surroundings, such as the force or pressure of the atmosphere on the surface of the Earth, and the force that liquids exert on the bottom and walls of a container. • Pressure is not only an important parameter for process control, but also as an indirect measurement for other parameters. 2 Pressure Measurement Pressure is most commonly expressed in – pounds per square inch (psi) in English units; or – Pascals (Pa) in metric units, which is the force in Newtons per square meter (N/m2). 3 Absolute, differential, and gauge pressures 1. Total vacuum is zero pressure or lack of pressure, as would be experienced in outer space, and is very difficult to achieve in practice. 2. Atmospheric pressure is the pressure on the Earth’s surface, due to the weight of the gases in the Earth’s atmosphere (14.7 psi or 101.36 kPa absolute). The pressure decreases above sea level. 3. Absolute pressure is the pressure measured with respect to a vacuum, and is expressed in psia or kPa(a). 4. Gauge pressure is the pressure measured with respect to atmospheric pressure, and is normally expressed in psig or kPa(g). Note the use of a and g when referencing the pressure to absolute and gauge. 5. Differential pressure is the pressure measured with respect to another pressure, and is expressed as the difference between the two values. This represents two points in a pressure or flow system, and is referred to as the “delta p,” or ∆p. 4 Other Definitions • Static pressure is the pressure of a fluid or gas that is stationary or not in motion. • Dynamic pressure is the pressure exerted by a fluid or gas when it impacts on a surface or an object due to its motion or flow. • Impact pressure (total pressure) is the sum of the static and dynamic pressures on a surface or object. 5 Pressure Gauges • Many of the devices used to monitor fluid pressure in industrial processes involve the monitoring of the elastic deformation of diaphragms, bellows and tubes. The following are some common examples of such sensors. 6 Diaphragms • Diaphragms consist of a thin layer or film of a material supported on a rigid frame. • The movement of the center of a circular diaphragm as a result of a pressure difference between its two sides is the basis of a pressure gauge. • The displacement will be proportional to the value of pressure difference. • The movement of the center of a diaphragm can be monitored by some form of displacement sensor. 7 Diaphragms • Pressure can be applied to one side of the film for gauge sensing, with the other inlet port being left open to the atmosphere. • Pressures can be applied to both sides of the film for differential sensing. • Absolute pressure sensing can be achieved by having a partial vacuum on one side of the diaphragm. • A wide range of materials can be used for the sensing film: from rubber to plastic for low pressures, silicon for medium pressures, and stainless steel for high pressures. 8 Diaphragms • When a pressure is applied to the diaphragm, the film distorts or becomes slightly spherical, and can be sensed using a strain gauge, piezoelectric, or changes in capacitance techniques. 9 Diaphragms • Sensing the position of the diaphragm using capacitance and ac bridge is very accurate, and excellent linear correlation between pressure and output signal amplitude can be obtained. 10 A Piezoelectric pressure sensor • When certain crystals, such as quartz and tourmaline, are stretched or compressed, electrical charges appear on their surfaces. This effect is called piezo-electricity. • As a result of the diaphragm movement a potential difference appears across it. 11 A Piezoelectric pressure sensor • The voltage produced by the crystal is proportional to Pressure exerted on the crystal surface. This voltage can be amplified, and hence the device is used as a pressure sensor. • This sensor does not require any voltage supply. • However, if the pressure keeps the diaphragm at a particular displacement, the resulting electrical charge is not maintained but leaks away. Therefore, this sensor is not suitable for static pressure measurements but is suitable for fast changing pressure. 12 Bellows • Bellows are a corrugated tube or a tube with convolutions. • When pressure is applied to the bellows, it elongates by stretching the convolutions, rather than the end diaphragms. • The bellows is the most sensitive of the mechanical devices for lowpressure measurements (i.e., 0.5 to 210 kPa). 13 Bellows • Bellows devices can be used for absolute, gauge, and differential pressure measurements. • Differential measurements can be made by mechanically connecting two bellows to be opposing each other when pressure is applied to them, as shown in below. • When pressures P1 and P2 are applied to the bellows, a differential scale reading is obtained. P2 could be atmospheric pressure for gauge measurements. 14 Using LVDT with bellows The LVDT can be used to convert the linear motion of a bellows into an electrical signal. The bellows converts the differential pressure between P1 and P2 into linear motion, which changes the position of the core in the LVDT. The device can be used as a gauge sensor when P2 is open to the atmosphere. 15 Bourdon tube • The Bourdon tube is C-shaped tube with an almost rectangular or elliptical cross-section made from e.g. stainless steel or phosphor bronze. • When the pressure inside the tube increases the closed end of the C opens out, thus the displacement of the closed end becomes a measure of the pressure. 16 Bourdon tube • The operating principle is that the outer edge of the cross section has a larger surface than the inner portion. When pressure is applied to the Bourdon tube, the outer edge has a proportionally larger total force applied because of its larger surface area, and hence the free end of the tube moves outward. • This movement can be mechanically coupled to a pointer, which will indicate pressure on a scale, or it can be coupled to a potentiometer, which will give a resistance value proportional to pressure as an electrical signal. • The Bourdon tube is reliable, inexpensive, and one of the most common general-purpose pressure gauges. 17 The bourdon tube pressure sensor. The bourdon tube (C-shaped portion) expands with pressure, turning the dial (below the bezel, not seen) through a leverage arm and gear mechanism. 18 Bourdon tube Bourdon tubes can also be shaped into helical or spiral shapes to increase their measurement range. 19