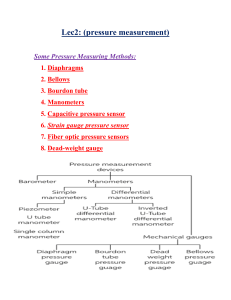

Various types of pressure gauges

advertisement

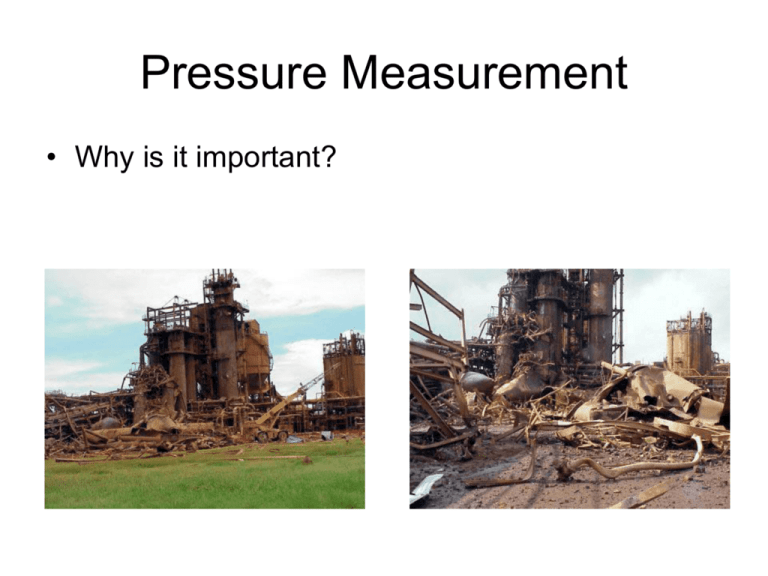

Pressure Measurement • Why is it important? Pressure Measurement • Asses the situation – What is the range of pressures to be measured? – Is pressure dynamic or static? – What is more important: absolute accuracy or good repeatability? – How much overpressure protection is required? Types of Measurement • Mechanical – U-tube manometer, Bourdon tube, Diaphragm and Bellows • Electrical – Strain Gauge, Capacitive sensor, Potentiometric, Resonant Wire, Piezoelectric, Magnetic, Optical Mechanical • Mechanical pressure measurement devices are large and cumbersome. • Not suited for automated control loops typical in industry. • Mechanical devices: – U-tube Manometer – Bourdon tube – Diaphragm and Bellows element U-tube Manometer • Measures difference in pressure between two points in a pipe. • Typical in laboratories. Bourdon Type • Flexible element used as sensor. • Pressure changes cause change in element position. • Element connected to pointer to reference pressure. Diaphragm and Bellows Element • Similar concept to Bourdon type. • Widely used because they require less space and can be made from materials that resist corrosion. Electrical • Have become more common with increased reliance on computerized control systems. Strain Gauge • Measures deflection of elastic diaphragm due to pressure difference across diaphragm. • Widely used in industry. • Used for small pressure ranges. • Measurements tend to drift. Capacitive Sensor • Measures changes in capacitance of electrically charged electrodes from movement of metal diaphragm due to pressure difference across diaphragm. Capacitive Sensor, cont. • Can be operated in balanced or unbalanced mode. – Balanced always has capacitance of zero. Measures pressure indirectly by measuring drift in capacitor arms. – Unbalanced measures ratio between output voltage and excitation voltage. • Widely used in industry. • Large rangeability. Resonant Wire • Wire is oscillated at resonant frequency by oscillator circuit. • Pressure changes cause change in wire tension which changes oscillatory frequency. • Generates digital signal. • Very precise, used for low differential pressure measurements. • Sensitive to temperature variation and has non-linear output Piezoelectric • Measures the charge developed across quartz crystal due to change in pressure. • Charge decays rapidly making unsuitable for static pressure measurements. • Sensors are very rugged. Pressure can be applied longitudinally or transversally. • Used to measure dynamic pressure changes associated with explosions and pulsations . Magnetic • Measures induced current caused by movement of magnetic components from pressure changes. • Used in applications where high resolution in small range is desired due to very high output signals. • Sensitive to stray magnetic fields and temperature changes. Optical • Detects effects of minute motions due to process pressure changes through partial blocking of an LED. • Immune to temperature effects. • Excellent stability and long-duration capability. Various types of pressure gauges Questions?