Valid Inequalities for Chemical Production

advertisement

Valid Inequalities for Chemical Production Scheduling

Sara Zenner and Christos T. Maravelias

Department of Chemical and Biological Engineering

University of Wisconsin – Madison - WI

s max 0, iI s

is i

s

S1

i max s

sSi

ζS1 = 45

50%

50% T1: 50

T2: 30

S1

ζS1 = 45 65

20

μ = 100

80%

Where?

Heater

Reactor 1

Reactor 2

Separator

When?

Heat/52

0

Heat/20

50

React2/50

React2/50

React1/50

React2/50

React1/80

React2/80

React3/80

React3/55

React2/70

Separate/80

Separate/55

2

3

4

5

6

7

8

9

k

j

min

j

jJi

10

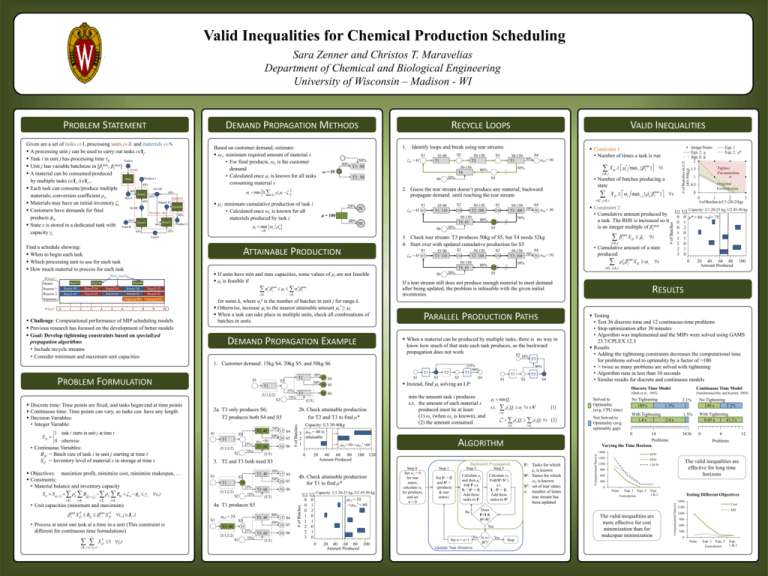

Challenge: Computational performance of MIP scheduling models

Previous research has focused on the development of better models

Goal: Develop tightening constraints based on specialized

propagation algorithms

• Include recycle streams

• Consider minimum and maximum unit capacities

S1

ζS1 = 45 65

jJi

S2

104

55-90

T1: 110

S6

PARALLEL PRODUCTION PATHS

10%

PROBLEM FORMULATION

T2

S3

50%

T1

25%

{U1,U2}

Objectives: maximize profit, minimize cost, minimize makespan, …

Constraints:

• Material balance and inventory capacity

Sst Sst 1 is Bij t is Bijt st st s s, t

ij

iI s

jJi

iI s

T1

25%

{U1,U2}

S2

S1

iI j tt ij 1

S3

55

25%

T1

{U1,U2}

S2

S1

T1 = 55

X 1 j , t

75%

T1: 60

S3

55

25%

{U1,U2}

P

ijt

20 S5

50 S6

T3: 60

3 T2 = 40 is

2 attainable

1

{U3}

0

T2: 40

50%

50%

15 S4

20 S5

20

S2

75%

T2: 40

50%

50%

T3: 60

{U3}

15 S4

20 S5

50 S6

0

0

0

1

1

2

2

3

S1

S2

S4

k

Q

s

S

is i s

iI s

s0 is Qi is Qi s

iI s

40

60

80

Amount Produced

100

U1

0

0

0

1

1

2

2

3

iI s

1

2

120

Step 0

Set ωs = 0

for tear

states,

calculate ωs

for products,

and set

n=0

Step 1

Set Ik = ∅

and Sk =

{products

& tear

states}

Calculate μi

and then μi*

∀i∉ Ik s.t.

Si+\ Sk = ∅.

Add these

tasks to Ik

Calculate ωs

∀s∉(Sk\ ST )

s.t.

Is-\ Ik = ∅.

Add these

states to Sk

Does

Ik=I &

Sk=S?

Set n = n+1

20 40 60 80 100

Amount Produced

Update Tear Streams

No Is n≥

|ST|?

Yes

Stop

0

U2 Capacity: U1 20-25 kg, U2 45-50 kg

0 * = 60 →̂ = 75

1

2

0

1

0

1

0

20 40 60 80

Amount Produced

Ik:

Tasks for which

μi is known

Sk: States for which

ωs is known

ST: set of tear states

n: number of times

tear stream has

been updated

100

Solved to

Optimality

(avg. CPU time)

Not Solved to

Optimality (avg.

optimality gap)

Discrete Time Model

Continuous Time Model

(Shah et al., 1993)

(Sundaramoorthy and Karimi, 2005)

No Tightening

189 s

2.1%

No Tightening

149 s

2.2%

1.5%

With Tightening

0.45 s

41.2 s

3436

0

1.3%

With Tightening

1.4 s

2.4 s

6

12

Problems

40 hr

1500

80 hr

1200

120 hr

The valid inequalities are

effective for long time

horizons

900

600

300

0

None

F1

Eqn.

F2 1 Eqn.

F3 2

Formulation

Eqn.

F4

1&2

Testing Different Objectives

1800

The valid inequalities are

more effective for cost

minimization than for

makespan minimization

Yes

Original

Formulation

0.5

0

14

Problems

Varying the Time Horizon

Backward Propagation

Step 2

Step 3

1

Testing

• Test 36 discrete-time and 12 continuous-time problems

• Stop optimization after 30 minutes

• Algorithm was implemented and the MIPs were solved using GAMS

23.7/CPLEX 12.3

Results

• Adding the tightening constraints decreases the computational time

for problems solved to optimality by a factor of >100

• > twice as many problems are solved with tightening

• Algorithm runs in less than 10 seconds

• Similar results for discrete and continuous models

1800

No

0

T2

i min Qi

s.t.

Tighter

Formulation

1.5

RESULTS

ALGORITHM

T3 =50→T3

T1 = 55

→T1* = 60

0

1

2

0

1

0

1

0

S3

* =60

U1 U2 Capacity: U1 20-25 kg, U2 45-50 kg

{U3}

• Cumulative amount of a state

produced

max

is j X ijt s s

Eqn. 1

Eqn. 2: μ*

0

1

2

3

# of Batches in U1 (20-25kg)

0

4b. Check attainable production

for T1 to find μ*

50 S6

T3: 60

4a. T1 produces S5

jmin X ijtP Bijt jmax X ijtP i, j J i , t

• Process at most one task at a time in a unit (This constraint is

different for continuous time formulations)

75%

T3 =50

50%

15 S4

Capacity: U3 30-40kg

3. T2 and T3 both need S3

jJi

• Unit capacities (minimum and maximum)

t

S3

S2

T1

min the amount task i produces

s.t. the amount of each material s

produced must be at least:

(1) ωs (when ωs is known), and

(2) the amount consumed

2b. Check attainable production

for T2 and T3 to find μ*

# of Batches

S1

50%

T2

T3

90%

Instead, find i solving an LP:

20 S5

{U3}

2a. T3 only produces S6;

T2 produces both S4 and S5

T2: 40

S1

15 S4

50 S6

75%

# of Batches

1 task i starts in unit j at time t

X ijt

0 otherwise

• Continuous Variables:

Bijt = Batch size of task i in unit j starting at time t

Sst = Inventory level of material s in storage at time t

S2

T3

T1

10%

90%

T3

S4

i

Integer Points

Eqn. 2: μ

Eqn. 2: μ̂

2

iI s , jJi ,t

52

S5

When a material can be produced by multiple tasks, there is no way to

know how much of that state each task produces, so the backward

propagation does not work

S3

DEMAND PROPAGATION EXAMPLE

jmax X ijt ˆi

i

50%

80%

Constraint 2

• Cumulative amount produced by

a task. The RHS is increased so it

is an integer multiple of βjmax

jJ ,t

S4

50-150

T3: 104 50% 50 φS4 = 50

S3

104

50-150

T2: 104

20%

1. Customer demand: 15kg S4, 20kg S5, and 50kg S6

Discrete time: Time points are fixed, and tasks begin/end at time points

Continuous time: Time points can vary, so tasks can have any length

Decision Variables:

• Integer Variable:

52

S5

X ijt s max i , j {is jmax } s

If a tear stream still does not produce enough material to meet demand

after being updated, the problem is infeasible with the given initial

inventories

for some k, where αjk is the number of batches in unit j for range k.

Otherwise, increase i to the nearest attainable amount i* ≥ i

When a task can take place in multiple units, check all combinations of

batches in units

S1

iIs , jJ i ,t

3. Check tear stream: T3 produces 50kg of S5, but T4 needs 52kg

4. Start over with updated cumulative production for S5

i kj jmax

50%

50%

80%

20%

S6

If units have min and max capacities, some values of μi are not feasible

μi is feasible if

Heat/48

• Number of batches producing a

state

S4

50-150

T3: 100 50% 50 φS4 = 50

S3

100

50-150

T2: 100

50-150

T4: 65

React1/50

1

S2

100

55-90

T1: 110

jJ ,t

X ijt i* max j { jmax } i

i

S5

50-150

T4: 65

ATTAINABLE PRODUCTION

How much?

80%

2. Guess the tear stream doesn’t produce any material; backward

propagate demand until reaching the tear stream

20%

Constraint 1

• Number of times a task is run

50%

20%

S6

S4

50-150

50%

φS4 = 50

T3

S3

50-150

T2

50-150

T4

Feed C

Find a schedule showing:

When to begin each task

Which processing unit to use for each task

How much material to process for each task

S2

55-90

T1

ω = 55

μi: minimum cumulative production of task i

• Calculated once ωs is known for all

materials produced by task i

is

Identify loops and break using tear streams

# of Batches in U2

(45-50kg)

1.

Based on customer demand, estimate:

ωs: minimum required amount of material s

• For final products, ωs is the customer

demand

• Calculated once µi is known for all tasks

consuming material s

VALID INEQUALITIES

Computational Time (s)

Given are a set of tasks iI, processing units jJ, and materials sS

A processing unit j can be used to carry out tasks iIj.

Task i in unit j has processing time τij

Feed A

Unit j has variable batchsize in [βjmin, βjmax]

Heater

A material can be consumed/produced

Product 1

Heat

by multiple tasks iIs-/iIs+.

40%

Int AB

Each task can consume/produce multiple

40%

10%

React2

materials; conversion coefficient ριs

60%

Hot A

Separator

60%

Impure E

Materials may have an initial inventory ζs

Separate

Int BC

Customers have demands for final

Reactors 1&2

90%

products ϕst

50%

React3

React1

Product 2

80%

State s is stored in a dedicated tank with Feed B

20%

50%

capacity γs

RECYCLE LOOPS

# of Batches

DEMAND PROPAGATION METHODS

Computational Time (s)

PROBLEM STATEMENT

Cost

1500

MS

1200

900

600

300

0

None

F1

Eqn.

F2 1

Eqn.

F3 2

Formulation

Eqn.

F4

1&2