Chapter 6: Inventory Control

advertisement

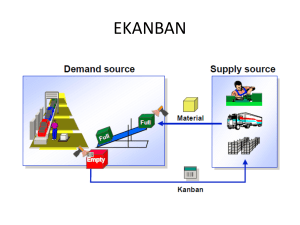

Chapter 6: Inventory Control 1.Reasons for Holding Inventories Summarize Sheet Final (2/2014) IBM4715: Designing and Managing Global Operations CH.6,8,9,10,11 Members: M2N Nunticha L. 5513961 Natcha K. 5513962 Rada C. 5514026 Economies of Scale Uncertainty in delivery lead times Speculation. Changing Costs Over Time Smoothing. Demand Uncertainty Costs of Maintaining Control System 2.Relevant Costs 1.Holding Costs - Costs proportional to the quantity of inventory held. 2.Ordering Cost (or Production Cost). Includes both fixed and variable components. 3.Penalty or Shortage Costs. All costs that accrue when insufficient stock is available to meet demand leading to Loss of revenue for lost demand, Costs of bookkeeping for backordered demands ,Loss of goodwill for being unable to satisfy demands 3. Inventory Systems 3.1Single-period inventory: One time purchasing decision and seeks to balance the costs of inventory overstock and under stock 3.2Multi-period Models: Demand for the product is constant and uniform throughout the period. Lead time (time from ordering to receipt) is constant. Price per unit of product is constant. Inventory holding cost is based on average inventory ,Ordering or setup costs are constant , all demands for the product will be satisfied---- FixedOrder Quantity Models ***Fixed-Order Quantity Models formula Question: An auto parts supplier sells Hardy-brand batteries to car dealers and auto mechanics. The annual demand is approximately 1,200 batteries. The supplier pays $28 for each battery and estimates that the annual holding cost is 30 percent of the battery’s value. It costs approximately $20 to place an order (managerial and clerical costs). The supplier currently orders 100 batteries per month. Determine the ordering, holding, and total inventory costs for the current order quantity and find EOQ? Solution: The current ordering and holding costs are : The EOQ is ***Quantity Discount Models ----divide into 2 methods All Units Discounts: the discount is applied to ALL of the units in the order. Gives rise to an order cost function such as that pictured in Figure 4-9 .For all units discounts, the optimal will occur at the bottom of one of the cost curves or at a breakpoint. (It is generally at a breakpoint.). One compares the cost at the largest realizable EOQ and all of the breakpoints succeeding it. Incremental Discounts: the discount is applied only to the number of units above the breakpoint. Gives rise to an order cost function such as that pictured in Figure 4-10. For incremental discounts, the optimal will always occur at a realizable EOQ value. Compare costs at all realizable EOQ’s. Chapter 8: Lean Production Lean Production can be defined as an integrated set of activities designed to achieve high-volume production using minimal inventories (raw materials, work in process, and finished goods) involves The elimination of waste in production effort The timing of production resources (i.e., parts arrive at the next workstation “just in time” Elimination of Waste 1. Focused factory networks 2. Group technology 3. Quality at the source 4. JIT production 5. Uniform plant loading 6. Kanban production control system 7. Minimized setup times Focused Factory Networks Small factories gather together because if let only one big firm responds for each region separately it has some eliminations such as Resource of quality labor – limited amount of qualified engineers Risk of the firm – economic, political, environmental risk Small, medium firms can be controlled easily Minimizing Waste: Group Technology Old Fashion – Department Specialization, Chaos order and slow Base on sequence – Lesser mistakes, easier Kanban • Card which indicates standard quantity of production • Derived from two-bin inventory system • Maintain discipline of pull production • Authorize production and movement of goods Kanban Production Control Systems Types of Kanban • Production kanban – authorizes production of goods • Withdrawal kanban – authorizes movement of goods • Kanban square – a marked area designated to hold items • Signal kanban – a triangular kanban used to signal production at the previous workstation • Material kanban – used to order material in advance of a process • Supplier kanban – rotates between the factory and suppliers Determining the Number of Kanbans Needed • Setting up a kanban system requires determining the number of kanbans cards (or containers) needed • Each container represents the minimum production lot size • An accurate estimate of the lead time required to produce a container is key to determining how many kanbans are required Respect for People • Level payrolls • Cooperative employee unions • Subcontractor networks • Bottom-round management style • Quality circles (Small Group Involvement Activities or SGIA’s) Lean Implementation Requirements: Design Flow Process • Link operations • Balance workstation capacities • Redesign layout for flow • Emphasize preventive maintenance Chapter 9: Facilities Location What is Logistics? • The movement of goods through the supply chain • “the art and science of and product in the proobtaining, producing, and distributing material per place and in proper quantities” How to best transport goods? Modes of transportation 1. Truck 2. Ship 3. Rail pipelines Warehouses 1. Consolidation 2. Cross Docking 3. Hub-and-Spoke systems Plant Location Methodology: Transportation Method of Linear Programming • Transportation method of linear programming seeks to minimize costs of shipping n units to m destinations or its seeks to maximize profit of shipping n units to m destinations. Plant Location Methodology: Centroid Method • The centroid method is used for locating single facilities that considers existing facilities, the distances between them, and the volumes of goods to be shipped between them. • This methodology involves formulas used to compute the coordinates of the twodimensional point that meets the distance and volume criteria stated above. Where Cx = X coordinate of centroid Cy = X coordinate of centroid dix = X coordinate of the its location diy = Y coordinate of the its location Vi = volume of goods moved to or from its location • To find what is the best location? 1. To begin, you must identify the existing facilities on a two- dimensional plane or grid and determine their coordinates. 2. You must also have the volume information on the business activity at the existing facilities. 3. You then compute the new coordinates using the formulas. 4. You then take the coordinates and place them on the map. Chapter 10: Quality Management 1.Meaning of Quality Consumer’s and producer perspectives depend on each other -Consumer’s perspective: PRICE ƒ -Producer’s perspective: COST Consumer’s view must dominate **** Quality of conformance: Making sure product or service is produced according to design. for example, if a hotel room is not clean when a guest checks, hotel is not functioning according to specifications of its design 2.Total Quality Management Partnering: a relationship between a company and its supplier based on mutual quality standard Customers: system must measure customer satisfaction Information Technology: infrastructure of hardware, networks, and software necessary to support a quality program Participative problem solving: employees involved quality management every employee has undergone extensive training to provide quality service to Disney’s guests Six Sigma A process for developing and delivering near perfect products and services. Measure of how much a process deviates from perfection. It allows managers to readily describe process performance using a common metric: Defects per Million Opportunities (DPMO) Cost of Quality : Cost of Achieving Good Quality --Prevention costs:costs incurred during product design --Appraisal costs: costs of measuring, testing, and analyzing Cost of Poor Quality: -- Internal failure costs include scrap, rework, process failure, downtime, include scrap, rework, process failure, downtime, and price reductions - - External failure costs include complaints, returns, warranty claims, include complaints, returns, warranty claims, liability, and lost sales Seven Quality Control Tools Seven Quality Control Tools 1.Pareto Analysis 2. Flow Chart 4.Histogram 5.Scatter Diagram 7. Cause--an d--Effect Diagram 3.Check Sheet 6. SPC Chart Chapter 11: Statistic Process Control Assignable variation is caused by factors that can be clearly identified and possibly managed. Also called special causes of variation Generally this is some change in the process Variations that can be traced to a specific reason The objective is to discover when assignable causes are present Eliminate the bad causes Incorporate the good causes Common/ Natural variation is inherent in the production process. Also called common causes Affect virtually all production processes Expected amount of variation Output measures follow a probability distribution For any distribution there is a measure of central tendency and dispersion If the distribution of outputs falls within acceptable limits, the process is said to be “In control” Process Capability • Tolerances – Design specifications reflecting product requirements • Process capability – Range of natural variability in a process what we measure with control charts Process capability index – Capability Index shows how well parts being produced fit into design limit specifications. – As a production process produces items small shifts in equipment or systems can cause differences in production performance from differing samples. – A Standard Measure of How Good a Process Is. We use a simple ratio to measure. – This is a “one-sided” Capability Index Concentration on the side which is closest to the specification - closest to being “bad”. – A capable process must have a Cpk of at least 1.0 – A capable process is not necessarily in the center of the specification, but it falls within the specification limit at both extremes Interpreting Cpk Types of Statistical Sampling • Attribute (Go or no-go information) – Defective refers to the acceptability of product across a range of characteristics. – Defects refer to the number of defects per unit which may be higher than the number of defectives. – p-chart application • Variable (Continuous) – Usually measured by the mean and the standard deviation. – X-bar and R chart applications Patterns in Control Charts Steps in Creating Control Charts 1. Take samples from the population and compute the appropriate sample statistic 2. Use the sample statistic to calculate control limits and draw the control chart 3. Plot sample results on the control chart and determine the state of the process (in or out of control) 4. Investigate possible assignable causes and take any indicated actions 5. Continue sampling from the process and reset the control limits when necessary Control Charts for Attributes For variables that are categorical - Good/bad, yes/no, acceptable/unacceptable Measurement is typically counting defectives Charts may measure - Percent defective (p-chart) Control Limits for p-Charts Population will be a binomial distribution, but applying the Central Limit Theorem allows us to assume a normal distribution for the sample statistics p = mean fraction defective in the sample z = number of standard deviations σp^ = standard deviation of the sampling distribution n = sample size Control Charts for Variables For variables that have continuous dimensions Weight, speed, length, strength, etc. X-charts are to control the central tendency of the process R-charts are to control the dispersion of the process These two charts must be used together Setting Chart Limits For x-Charts when we know σ Upper control limit (UCL) = x + zσx Lower control limit (LCL) = x - zσx x = mean of the sample means or a target value set for the process z = number of normal standard deviations σx = standard deviation of the sample means = σ/ n σ = population standard deviation n n = sample size R – Chart Type of variables control chart Shows sample ranges over time Difference between smallest and largest values in sample Monitors process variability Independent from process mean Upper control limit (UCLR) = D4R Lower control limit (LCLR) = D3R R = average range of the samples D3 and D4 = control chart factors from Table S6.1 Acceptance Sampling Form of quality testing used for incoming materials or finished goods Take samples at random from a lot (shipment) of items Inspect each of the items in the sample Decide whether to reject the whole lot based on the inspection results Only screens lots; does not drive quality improvement efforts Operating Characteristic Curve Shows how well a sampling plan discriminates between good and bad lots (shipments) Shows the relationship between the probability of accepting a lot and its quality level Average Outgoing Quality Pd = true percent defective of the lot Pa = probability of accepting the lot N = number of items in the lot n = number of items in the sample 1. If a sampling plan replaces all defectives 2. If we know the incoming percent defective for the lot We can compute the average outgoing quality (AOQ) in percent defective The maximum AOQ is the highest percent defective or the lowest average quality and is called the average outgoing quality level (AOQL) SPC and Process Variability -----------------------------------------------END----------------------------------------------