Protected Agriculture Course

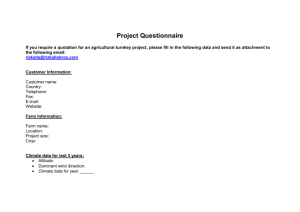

advertisement