The 5 Base Metals

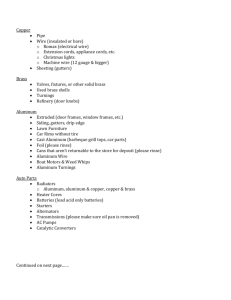

advertisement

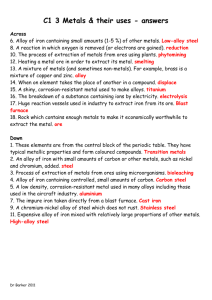

The 5 Base Metals STEEL STAINLESS STEEL CAST IRON COPPER/BRASS ALUMINUM Steel – A Ferrous Metal A iron alloy containing less than 2% carbon Melting point of 1535 degrees C or 1535 degrees F 2795 Boils From at 3000 degrees C or 5432 degrees F Iron, add coke, limestones lots of air and boom steel is created Steel Forms Bars – Solid shapes, hot or cold rolled, rounds, squares, or flats Billets – A section of an ingot Blooms – A slab of steel, usually the same thickness and width Plates – Large flat slabs thicker than ¼” (inch) Shapes – Can be in the forms of beams or any other shape needed Sheets – Hot or cold rolled with varying thicknesses Wires – Drawn form bars of steel Steel Nomenclature Created by S.A.E and A.I.S.I Referred to by a four digit designation (e.g. 1060, 8620, 4340) The first two digits refer to types of alloys in the steel (e.g. 1018 means it is plain carbon) The last two digits refer to the carbon content in hundredths (e.g. 1018 is .18% carbon. 1018 means that we have a plain carbon steel with .18% carbon Stainless Steel – A Ferrous Metal A iron alloy containing less than 2% carbon Contains chromium and sometimes nickel Melting point Boiling of 1535 degrees C or 2795 degrees F point of 3000 degrees C or 5432 degrees F Why do we use Stainless Steel? Better aesthetics Minimizes Can oxidation and corrosion have the ability to be ultrahigh-strength steel Stainless Steel Classification Designated with the same 4 digit coding of steel Ferritic 11 to 27 percent chromium Low carbon content (.1 to .35 percent) Used in jewelry, car accessories, and is considered very weak Austenitic Non-magnetic 16 to 26 chromium and 6 to 22 percent nickel Very low carbon content Wieldable, somewhat machinable, but cannot be hardened by heat treatments Used in low strength structural purposes Martensitic Higher carbon content .15 to 1.2 percent 4 to 18 percent chromium with usually no nickel Magnetic Not easily machined or welded but possible Good for knives and such Cast Iron – A Ferrous Metal Contains 2% or more carbon Can be Gray, White, Ductile, Malleable, or Wrought Somewhat unpredictable to work with due to its high carbon content Two most common are Gray and White Cast Iron Gray Most Common type of cast iron About 4% carbon Cheap to make, good compression strength, good machinability, and good vibration dampening Broken up into three classes based on minimum tensile strength Class 20 – 20,000 lb/in^2 Class 40 – 40,000 lb/in^2 Class 60 – 60,000 lb/in^2 Cast Iron White 2.5 to 3.5 percent carbon and .5 to 1.5 percent silicon and 1 to 3 percent nickel, molybdenum, or chromium Same Very class system as Gray Cast Iron hard and very brittle Great wear resistance Ideal for rolling/crushing machines or tools Cast Iron Ductile – ability to be drawn into a wire 4% carbon and 2.5% silicon Is composed of spherulites (Key factor in the ductile part) This removes the stress risers which potentially allow cracking in the metal Tensile strength at around 120,000 lb/in^2 Designated by three individual number sets e.g. 60:40:18, 65:45:12 First Set – Tensile Strength (amount of energy required to rip the material apart) Second Set – Yield Strength (the point at which the material begins to deform) Set – Percent Ultimate Elongation (the permanent deformation of the material) Third Copper/Brass – A Non-ferrous Metal Copper One of the first metals used Dozens of types of ores but not many are commercially important Predominantly found in Michigan, Utah, Nevada, Montana, Arizona, Alaska, Chile, Canada, Africa, England, Spain, Peru, Mexico, and Bolivia Most practical copper is found near the surface of the earth Usually used for wire and electrical components (must be extremely pure) Good conductivity and good corrosion resistance but will react with sulfur, oxygen, and chlorine when heated Its tensile strength is considerably less than steel and it modulus of elasticity is roughly half that of steel Copper/Brass Continued Brass A type of Copper, Bronze, and Zinc However may contain more elements besides Copper and Zinc Roughly, Brass is 70% Copper, 29% Zinc, and 1% Tin Most common types are Muntz, Red, and Free Machining Muntz – also called Malleable Brass, is 60% Copper and 40% Zinc Red – 85% Copper and 15% Zinc Tensile strength of 52,000 lb/in^2 Tensile strength of 38,000 lb/in^2 but can be cold rolled (Hardened) to 70,000 lb/in^2 Free Machining 60% Copper, 40% Zinc, .75% Tin, and .25% Lead Aluminum – A Non-ferrous Metal Second most abundant metallic element in the Earth’s crust Never found in a pure natural form 1/3 the weight of steel or copper Easily recyclable (maintaining 100% reuse) Melting Point: 1,220.58 degrees Fahrenheit (660.32 degrees Celsius) Boiling Point: 4,566 degrees F (2,519 degrees C) Refined made readily useable by the Bayer and Hall–Héroult processes Aluminum Continued Why do we use Aluminum? Light in weight Strong Noncorrosive Nonsparking Nonmagnetic Nontoxic Noncombustible. Aluminum Continued Aluminum is a very versatile metal It is used in the auto and aero space industry due to lightness and durability It is used in many situations where sparks or fire are concerns It is generally thought of as more versatile than steel Aluminum Continued Aluminum Code System Good online sources (http://www.esab.ca/ca/en/education/blog/understanding-thealuminum-alloy-designation-system.cfm and http://www.kanabco.com/vms/eng_metal_stds/eng_metal_stds_06.html ) Wrought Aluminum (4 digit codes) Cast Alloy Designation (3 digit codes) The Aluminum Temper Designation (letter designation) F (As Fabricated) O (Annealed) H (Strain Hardened) W (Solution Heat Treated) T (Thermally Treated) Commercial Grading (8 digit code) Formability or Workability Weldability Machining Corrosion Resistance Heat Treating Strength Typical Applications Alloy 1100 Excellent Excellent Good Excellent No Low Metal Spinning Alloy 2011 Good Poor Excellent Poor Yes High General Machining Alloy 2024 Good Poor Fair Poor Yes High Aerospace Application Alloy 3003 Excellent Excellent Good Good No Medium Chemical Equipment Alloy 5052 Good Good Fair Excellent No Medium Marine Applications Alloy 6061 Good Good Good Excellent Yes Medium Structural Applications Alloy 6063 Good Good Fair Good Yes Medium Architectural Applications Alloy 7075 Poor Poor Fair Average Yes High Aerospace Applications