Chapter 3 : Material Balance PART 1 ERT 214, Sem 1 2015/2016

advertisement

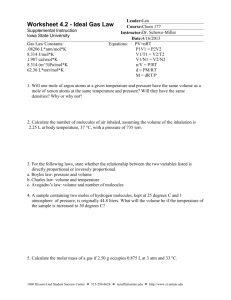

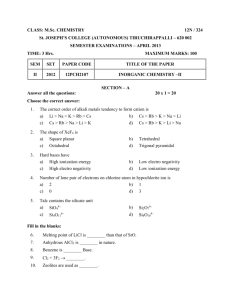

CHAPTER 3 MATERIAL BALANCE PART I Sem 1, 2015/2016 ERT 214 Material and Energy Balance / Imbangan Bahan dan Tenaga OBJECTIVES Students will be able to identify types of processes; batch, semi-batch and continuous Students will be able to perform Degree of Freedom Analysis Students will be able to perform Material Balance on Single Unit, Multiple Unit, Nonreactive process under steady state condition Process Classification Three type of process 1. Batch process Feed is charge to the process and product is removed when the process is completed No mass is fed or removed from the process during the operation Used for small scale production Operate in unsteady state 2. Continuous process Input and output is flow continuously throughout the duration of the process Operate in steady state Used for large scale production 3. Semi-batch process Neither batch nor continuous During the process a part of reactant can be fed or a part of product can be removed. Operate in unsteady state 1. Steady state 2. All the variables (i.e. temperatures, pressure, volume, flow rate, etc) do not change with time (eg: continuous process) Minor fluctuation can be acceptable Unsteady state or transient Process variable change with time, in particular mass flow rate. (eg; batch and semibatch) Test Yourself Define type and operation of process given below A balloon is filled with air at steady rate of 2 g/min A bottle of milk is taken from the refrigerator and left on the kitchen Water is boiled in open flask Answer • Semibatch and unsteady state • Batch and unsteady state • Semibatch and unsteady state Balances General Balance A balance on a conserved quantity (total mass, mass of a particular species, energy, momentum) in a system ( a single process unit, a collection of units, or an entire process) may be written in the following way: INPUT + GENERATION – OUTPUT – CONSUMPTION = ACCUMULATION (Enters through system boundaries) (Produced within system) (Leave through system boundaries) (Consumed within system) (Buildup within system) Differential vs. Integral Balances Two types of balances may be written: 1. Differential balances balances that indicate what is happening in a system at an instant time. balance equation is a rate (rate of input, rate of generation, etc.) and has units of the balanced quantity unit divided by a time unit (people/yr, g SO2/s). usually applied to a CONTINUOUS process. 2. Integral balances Balances that describe what happens between two instants of time. balance equation is an amount of the balanced quantity and has the corresponding unit (people, g SO2). usually applied to a BATCH process, with the two instants of time being the moment after the input takes place and the moment before the product is withdrawn. Simplified Rule for Mass Balance If the balanced quantity is TOTAL MASS, set generation = 0 and consumption = 0. Mass can neither be created nor destroyed. If the balanced substances is a NONREACTIVE SPECIES (neither a reactant nor a product), set generation = 0 and consumption = 0. If a system is at STEADY STATE, set accumulation = 0, regardless of what is being balanced. Balances on Continuous Steady State Process General Mass Balance Equation (GMBE) INPUT + GENERATION – OUTPUT – CONSUMPTION = ACCUMULATION Steady state: accumulation = 0 INPUT + GENERATION – OUTPUT – CONSUMPTION = 0 If balance on nonreactive species or total mass; balance equation become (generation=consumption=0) INPUT = OUTPUT Non-reactive processes Processes that undergo without chemical reaction Depends on the physical / environmental factors like temperature, volume, pressure, Example Material Balances on a Continuous Distillation Process One thousand kilograms per hour of a mixture of benzene (B) and toluene (T) containing 50% benzene by mass is separated by distillation into two fractions. The mass flow rate of benzene in the top stream is 450 kg Blh and that of toluene in the bottom stream is 475 kg T/h. The operation is at steady state. Write balances on benzene and toluene to calculate the unknown component flow rates in the output streams. The process can be depicted schematically as follows: Benzene Balance 500 kg B/h = 450 kg B/h + m2 m2 = 50 kg B/h Toluene Balance Since the process is at steady state there can be no buildup of anything in the system, so the accumulation term equals zero in all material balances. In addition, since no chemical reactions occur, there can be no nonzero generation or consumption terms. For all balances, Equation 4.2-2 therefore takes the simple form input = output. 500 kg B/h = 475 kg B/h + m1 m1 = 25 kg T/h Check the calculation: Total Mass Balance 1000 kg /h = 450 + m1+m2+475 (all in kg/h) ml = 25 kg T/h M2= 50kg B/h 1000 kg/h = 1000 kg/h Integral Balances on Batch Process Ammonia is produced from nitrogen and hydrogen in a batch reactor. At time t = 0 there are n0 mol of NH3 in the reactor, and at a later time tf the reaction terminates and the contents of the reactor, which include nf ammonia, are withdrawn. Between t0 and tf no ammonia enters or leaves through the reactor boundaries. General Mass Balance Equation (GMBE) INPUT + GENERATION – OUTPUT – CONSUMPTION = ACCUMULATION From GMBE: (input=0; output=0) Generation – Consumption = Accumulation For batch reactor: Accumulation = Final output – Initial Input Final GMBE for batch process Initial input + Generation = Final output + Consumption Example Balances on a Batch Mixing Process Two methanol-water mixtures are contained in separate flasks. The first mixture contains 40.0 wt% methanol, and the second contains 70.0 wt% methanol. If 200 g of the first mixture is combined with 150 g of the second, what are the mass and composition of the product? Observe that the input and output "streams" shown on the chart denote the initial and final states for this batch process. Since no reactions are involved, the generation and consumption may be omitted so that all balances have the simple form "input = output.“ Total Mass Balance: 200 g + 150 g = m m = 350 g Methanol Balance : 200 g 0.4 g CH3OH + 150 g g m = 350 g, So….. X = 0.529 g CH3OH/g Check the solution: Water Balance : input = output (200)(0.6) + (150)(0.3) = (300)(1-0.529) 0.7 g CH3OH g = mg x g CH3OH g Example Integral Balances on Semi-Batch Process Air is bubbled through a drum of liquid hexane at a rate of 0.100 kmol/min. The gas stream leaving the drum contains 10.0 mole% hexane vapor. Air may be considered insoluble in liquid hexane. Use an integral balance to estimate the time required to vaporize 10.0 m3 of the liquid. We begin with a differential balance on air. Since we assume that air neither dissolves in the liquid (accumulation = 0) nor reacts with hexane in the process unit (generation = consumption = 0). the balance reduces to input = output: Integral hexane balance, proceeding from time t = 0 to t = tf(min), the time we seek to calculate. The balance has the form accumulation = -output (verify). The accumulation term, which is the total change in the moles of liquid hexane in the system during time tf. Must be negative since hexane is being lost from the system. Since the total number of moles of hexane evaporated occupied a liquid volume of 10.0 m3and the specific gravity of liquid hexane is 0.659, the accumulation term equals The output term in the balance is the rate at which hexane is leaving the system [0.1n (kmol C6H14/min)] times the total process time, tf (min). The balance (accumulation = -output) is therefore Flowcharts When you are given process information and asked to determine something about the process, ORGANIZE the information in a way that is EASY for subsequent calculations. The best way draw a flowchart using boxes or other symbols to represent process units (reactors, mixers, separation units, etc.) lines with arrows to represent inputs and outputs. Flowcharts The flowchart of a process can help get material balance calculations started and keep them moving. Flowchart must be fully labeled when it is first drawn, with values of known process variables and symbols for unknown variables being written for each input and output stream. Flowchart will function as a scoreboard for the problem solution: as each unknown variable is determined its value is filled in, so that the flowchart provides a continuous record of where the solution stands and what must still be done. Flowcharts Labeling Write the values and units of all known stream variables at the locations of the streams on the flowchart. For example, a stream containing 21 mole% O2 and 79% N2 at 320˚C and 1.4 atm flowing at a rate of 400 mol/h might be labeled as: 400 mol/h 0.21 mol O2/mol 0.79 mol N2/mol T = 320˚C, P = 1.4 atm Flowcharts Labeling Process stream can be given in two ways 1. As the total amount or flow rate of the stream and the fractions of each component 100 kmol/min 60 kmol N2/min 40 kmol O2/min 2. 0.6 kmol N2/kmol 0.4 kmol O2/kmol Or directly as the amount or flow rate of each component. 10 lbm 3.0 lbm CH4 4.0 lbm C2H4 3.0 lbm C2H6 0.3 lbm CH4/lbm 0.4 lbm C2H4/lbm 0.3 lbm C2H6/lbm Flowcharts Labeling Assign algebraic symbols to unknown stream variables [such as m (kg solution/min), x (lbm N2/lbm), and n (kmol C3H8)] and write these variable names and their associated units on the flowchart. n mol/h 0.21 mol O2/mol 0.79 mol N2/mol T = 320˚C, P = 1.4 atm 400 mol/h y mol O2/mol (1-y) mol N2/mol T = 320˚C, P = 1.4 atm Example : Flowchart An experiment on the growth rate of certain organism requires an environment of humid air enriched in oxygen. Three input streams are fed into an evaporation chamber to produce an output stream with the desired composition. A: Liquid water fed at rate of 20 cm3/min B: Air (21% O2 and 79% N2) C: Pure O2 with a molar flow rate one-fifth of the molar flow rate of stream B The output gas is analyzed and is found to contain 1.5 mole% water. Draw and label the flowchart of the process, and calculate all unknown stream variables. 0.200n1 mol O2/min n1 mol air/min 0.21 mol O2 /mol 0.79 mol N2 /mol n 3 mol/min Evaporation 0.015 mol H2O /mol y mol O2 /mol (0.985-y) mol N2/mol 20 cm3 H2O (l)/min n 2mol H2O/min Notes on the Labeling: 1. Since the one known flow rate (20 cm3 H20/min) is given on a per minute basis, it is most convenient to label all stream flow rates on this basis. 2. Once the variable name (n1 is chosen for the air flow rate, the given information about the ratio of the air and O2flow rates may be used to label the O2 flow rate 0.200 nl. 3. The mole fractions of the components of any stream must add up to 1. Since the mole fraction of H20 in the outlet stream is known to be 0.015, once the mole fraction of O2 is labeled y, that of N2 must be 1 - 0.015 - y) = (0.985 - y) (mol N2/mol). 0.200n1 mol O2/min n1 mol air/min 0.21 mol O2 /mol 0.79 mol N2 /mol n 3 mol/min Evaporation 0.015 mol H2O /mol y mol O2 /mol (0.985-y) mol N2/mol 20 cm3 H2O (l)/min n 2 mol H O/min 2 The quantity n2 may be calculated from the given volumetric flow rate and the density of liquid water (conversion unit): The three remaining unknowns (nl' n3, and y) may be determined from balances, all of which have the simple form input = output for this nonreactive steady-state process. The balances are easily written by referring to the flowchart. Flowcharts Labeling If that the mass of stream 1 is half that of stream 2, label the masses of these streams as m and 2m rather than m1 and m2. If you know that mass fraction of nitrogen is 3 times than oxygen, label mass fractions as y g O2/g and 3y g N2/g rather than y1 and y2. When labeling component mass fraction or mole fraction, the last one must be 1 minus the sum of the others If volumetric flow rate of a stream is given, it is generally useful to label the mass or molar flow rate of this stream or to calculate it directly, since balance are not written on volumetric qualities Consistent on Notation m mass mass flow rate m n moles n molar flow rate V volume volume flow rate V x component fraction (mass or moles) in liquid y moles fraction in gas Flowchart Scaling & Basis of Calculation Flowchart scaling – procedure of changing the values of all stream amounts or flow rates by a proportional amount while leaving the stream compositions unchanged. The process would still be balance. 1) Scaling-up – if final stream quantities are larger than the original quantities. 2) Scaling down – if final stream quantities are smaller than the original quantities. Flowchart Scaling & Basis of Calculation 1 kg C6H6 1 kg C7H8 300 kg C6H6 300 kg C7H8 300 lbm/h 300 lbm/h x 300 2 kg 0.5 kg C6H6/kg 0.5 kg C7H8/kg 600 kg 0.5 kg C6H6/kg 0.5 kg C7H8/kg kg kg/h Replace kg with lbm 600 lbm/h 0.5 lbm C6H6/lbm 0.5 lbm C7H8/lbm Flowchart Scaling & Basis of Calculation Suppose you have balanced a process and the amount or flow rate of one of the process streams is n1.You can scale the flow chart to make the amount or flow rate of this stream n2 by multiplying all stream amounts or flow rate by the ratio n2/n1. Scaling Factor= Desired amount / Old amount You cannot, however, scale masses or mass flow rates to molar quantities or vice versa by simple multiplication; conversions of this type must be carried out using the methods as discussed in mass fraction and mol fraction section. Example : Scale Up of a Separation Process Flowchart A 60-40 mixture (by moles) of A and B is separated into two fractions. A flowchart of the process is shown here. It is desired to achieve the same separation with a continuous feed of 1250 lb-moles/h. Scale the flowchart accordingly. desired Balancing a Process 3.0 kg/min of benzene and 1.0 kg/min of toluene are mixed 3 kg C6H6/min m (kg/min) 1 kg C7H8/min x (kg C6H6/kg) (1-x) (kg C7H8/kg) Two unknown quantities – m and x, associated with process, so two equations are needed to calculate them. For NONREACTIVE STEADY STATE process, input = output. 3 possible balance can be written – Balance on total mass, benzene, and toluene – any two of which provide the equations needed to determine m and x. For example, Total Mass Balance: 3.0 kg/min + 1.0 kg/min = m kg/min = 4.0 kg/min Benzene Balance: 3.0 kg C6H6/min = 4.0 kg/min (x kg C6H6/kg) x = 0.75 kg C6H6/kg Balancing a Process Which balance to be used when a choice exists and the order in which these balanced should be written? Rules of thumb for NONREACTIVE process 1. 2. The maximum number of independent equations that can be derived by writing balances on a nonreactive system equals the number of chemical species in the input and output streams. Write balances first that involve the fewest unknown variables. Non-reactive processes Processes that undergo without chemical reaction Depends on the physical / environmental factors like temperature, volume, pressure, Basis of Calculation Balanced process can always be scaled. Mean that material balance calculation can be performed on the basis of any convenient set of stream amount or flow rate and the results can afterward be scaled to any desired extent. A basis of calculation is an amount (mass or moles) of flow rate (mass or molar) of one stream or stream component in a process. All unknown variables are determined to be consistent with the basis. If a stream amount or flow rate is given in problem, choose this quantity as a basis If no stream amount or flow rate are known, assume one stream with known composition. If mass fraction is known, choose total mass or mass flow rate as basis. If mole fraction is known, choose a total moles or molar flow rate as basis Example : Balance on Mixing Unit An aqueous solution of NaOH contains 20.0% NaOH by mass. It is desired to produce an 8.0% NaOH solution by diluting a stream of the 20% solution with a stream of pure water. Calculate the ratios (liters H20/kg feed solution) and (kg product solution/kg feed solution). Solution: Choose a basis of calculation-an amount or flow rate of one of the feed or product streamsand then draw and label the flowchart. We will arbitrarily choose a basis of 100 kg of the 20% feed solution. (We could also have chosen a flow rate of 100 Ibm/min of the 8% product solution or 10 tons of diluent water. The final results do not depend on the basis chosen since we are only asked to find ratios of stream amounts.) The flowchart appears as follows: input = output. Total mass balance 100 kg + ml = m2. NaOH Balance Total mass balance (input = output). Diluent water volume. Although we are not given the temperature or pressure at which the mixing is done, the density of liquid water is approximately constant at 1.00 kg/liter. So, Ratios requested in problem statement. ratios (liters H20/kg feed solution) and (kg product solution/kg feed solution). Degree-of-Freedom Before doing any material balance calculation, use a properly drawn and labeled flowchart to determine whether there is enough information to solve a given problem. The procedure for doing so is referred to as degree-of-freedom analysis. Procedure to perform a degree-of-freedom analysis: a) draw and completely label a flowchart b) count the unknown variables on the chart (n unknowns) c) count the independent equations (n indep. eq.) d) Find number of degree-of-freedom (ndf) ndf= n unknowns - n indep. eq. Number of Degree-of-Freedom Three possibilities number of degree-of-freedom (n df) 1. If ndf = 0 the problem can in principle be solved. 2. If ndf > 0 there are more unknowns than independent equations relating to them at least ndf additional variable values must be specified before remaining variable values can be determined. Either relations have been overlooked or the problem is underspecified. 3. If ndf < 0 there are more independent equations than unknowns. Either the flowchart is incompletely labeled or the problem is over specified with redundant and possibly inconsistent relations. There is little point wasting time trying to solve material balance for n df > 0 or n df <0. Sources of Equation for Balance Material balances. An energy balance. Process specifications (when problem statement specify process variables) Physical properties and Laws (eg: equation of state for gases etc) Physical constrains (eg:if the mole fractions of the three components of a stream are labeled XA, XB, and Xc, then a relation among these variables is XA +XB +Xc =1) General Procedure for Single Unit Process Material Balance Calculation 1. 2. 3. 4. 5. 6. 7. 8. 9. Choose as basis of calculation an amount or flow rate of one of the process streams. Draw a flowchart and fill in all unknown variables values, including the basis of calculation. Then label unknown stream variables on the chart. Express what the problem statement asks you to determine in terms of the labeled variables. If you are given mixed mass and mole units for a stream (such as a total mass flow rate and component mole fractions or vice versa), convert all quantities to one basis. Do the degree-of-freedom analysis. If the number of unknowns equals the number of equations relating them (i.e., if the system has zero degree of freedom), write the equations in an efficient order (minimizing simultaneous equations) and circle the variables for which you will solve. Solve the equations. Calculate the quantities requested in the problem statement if they have not already been calculated. If a stream quantity or flow rate ng was given in the problem statement and another value nc was either chosen as a basis or calculated for this stream, scale the balanced process by the ratio ng/nc to obtain the final result. BALANCE ON MULTIPLE UNIT PROCESSES Balances on Multiple Unit Processes In real chemical industries, more than one unit processes exist such as a separation unit after reactor and so on. Need to know term called SYSTEM in order to solve material problem SYSTEM: Any portion of process that can be enclosed within a hypothetical box (or boundary) It can be the entire process, an interconnected of process unit, a single unit, a point which two or more stream come together into one stream or etc. The inputs and outputs to a system are the process streams that are intersect to the system boundary System of Multiple Unit Processes C A D B E Balances on Multiple Unit Processes Solving material balances in multiple unit process is basically the same as single unit processes In multiple unit, must isolate and write balance on several subsystems to obtain enough equation to determine all unknowns stream variables Always perform degree-of-freedom analysis before solving a material balance of system. Example : Balance on Two Unit Process A labeled flowchart of a continuous steady-state two-unit process is shown below. Each stream contains two components, A and B, in different proportions. Three streams whose flow rates and/or compositions are not known are labeled 1,2, and 3. Calculate the unknown flow rates and compositions of streams 1,2, and 3. Basis-Given Flow Rates The systems about which balances might be written are shown on the following representation of the flowchart: The outer boundary encompasses the entire process and has as input and output streams all of the streams that enter and leave the process. Two of the interior boundaries surround individual process units, and the third encloses a stream junction point. RECYCLE & BYPASS RECYCLE BYPASS Recycle stream Bypass stream Eg: Unused reactant, recovery catalyst etc Fraction of the feed to process unit is diverted around the unit and combined with the output stream from the unit. Example: RECYCLE PROCESS Material and Energy Balances on an Air Conditioner Fresh air containing 4.00 mole% water vapor is to be cooled and dehumidified to a water content of 1.70 mole% H20. A stream of fresh air is combined with a recycle stream of previously dehumidified air and passed through the cooler. The blended stream entering the unit contains 2.30 mole% H20. In the air conditioner, some of the water in the feed stream is condensed and removed as liquid. A fraction of the dehumidified air leaving the cooler is recycled and the remainder is delivered to a room. Taking 100 mol of dehumidified air delivered to the room as a basis of calculation, calculate the moles of fresh feed, moles of water condensed, and moles of dehumidified air recycled. The labeled flowchart for this process, including the assumed basis of calculation, is shown below. Dashed lines depict the four subsystems about which balances might be written-the overall process, the recycle-fresh feed mixing point, the air conditioner, and the recycle-product gas splitting point. The quantities to be determined are n1, n3, and n5. All balances have the form input = output, and each additive term in each equation has the units (mol of the balanced quantity). THANK YOU MID TERM EXAM 1 WEEK 8 (26 – 30 Oct 2015) TUESDAY, 27 Oct 2015 DKD3 (10 am-12.00 pm)